Gas filter

A filter and gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as filter blockage, reduced gas output, filter blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

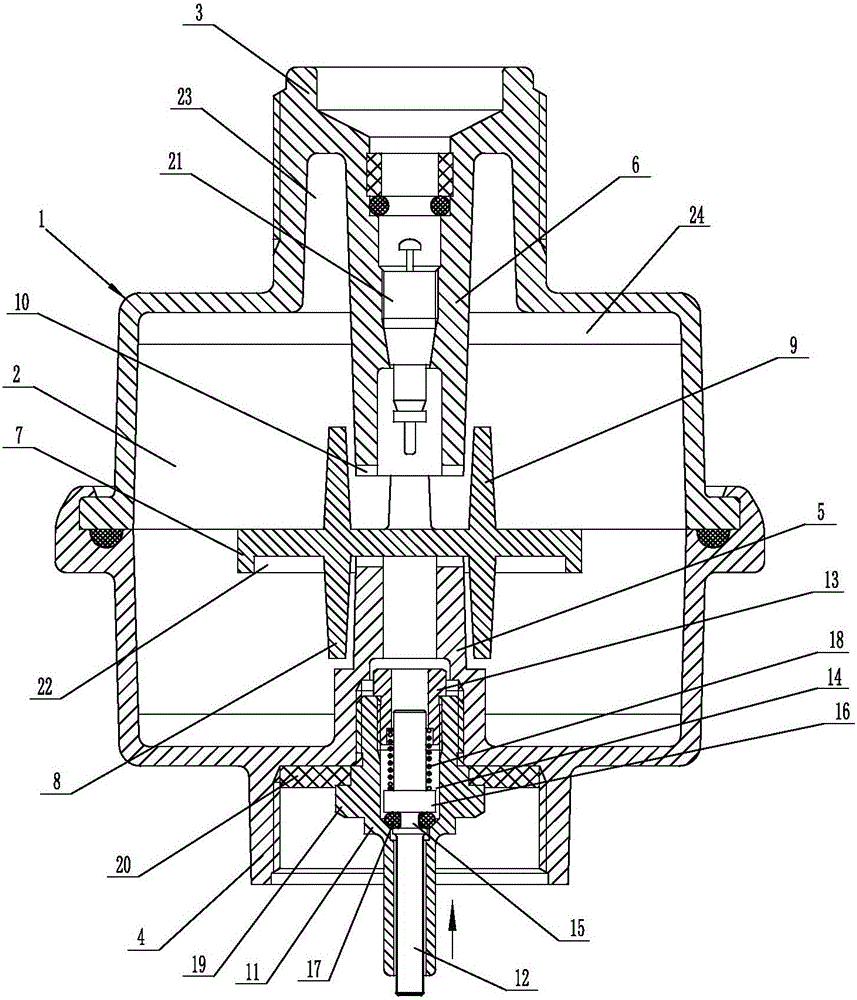

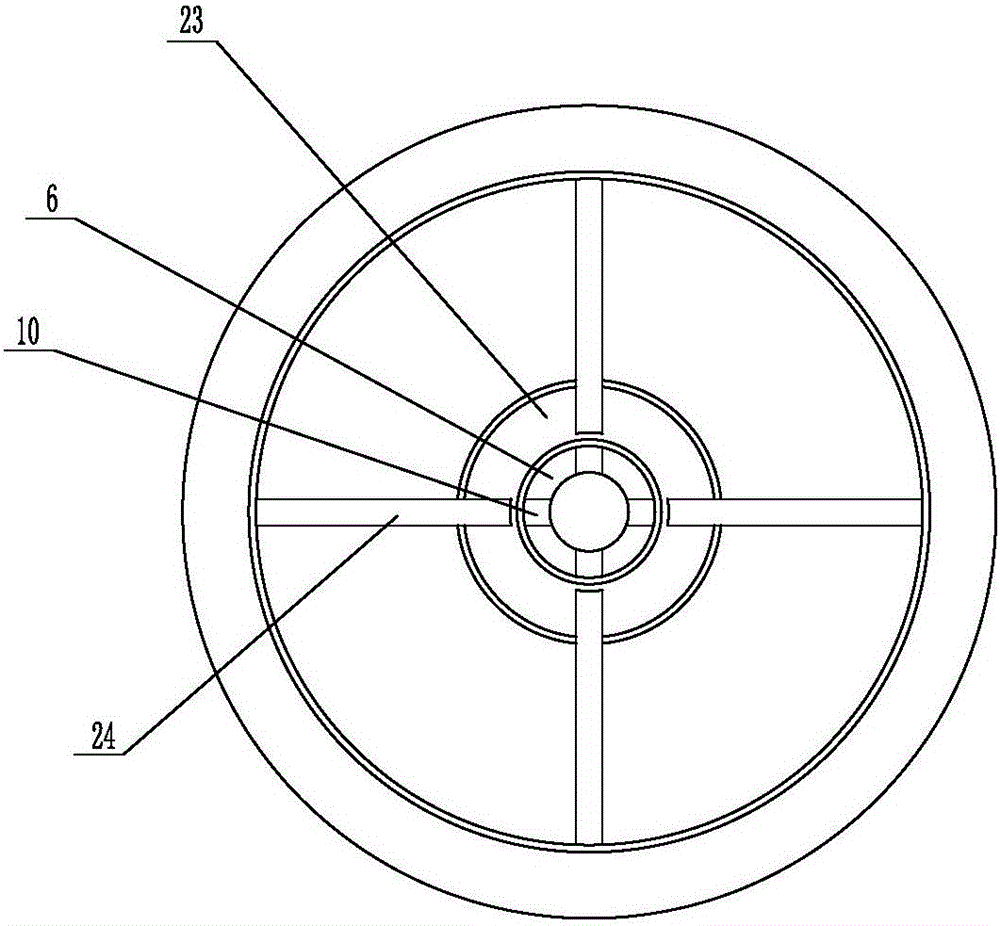

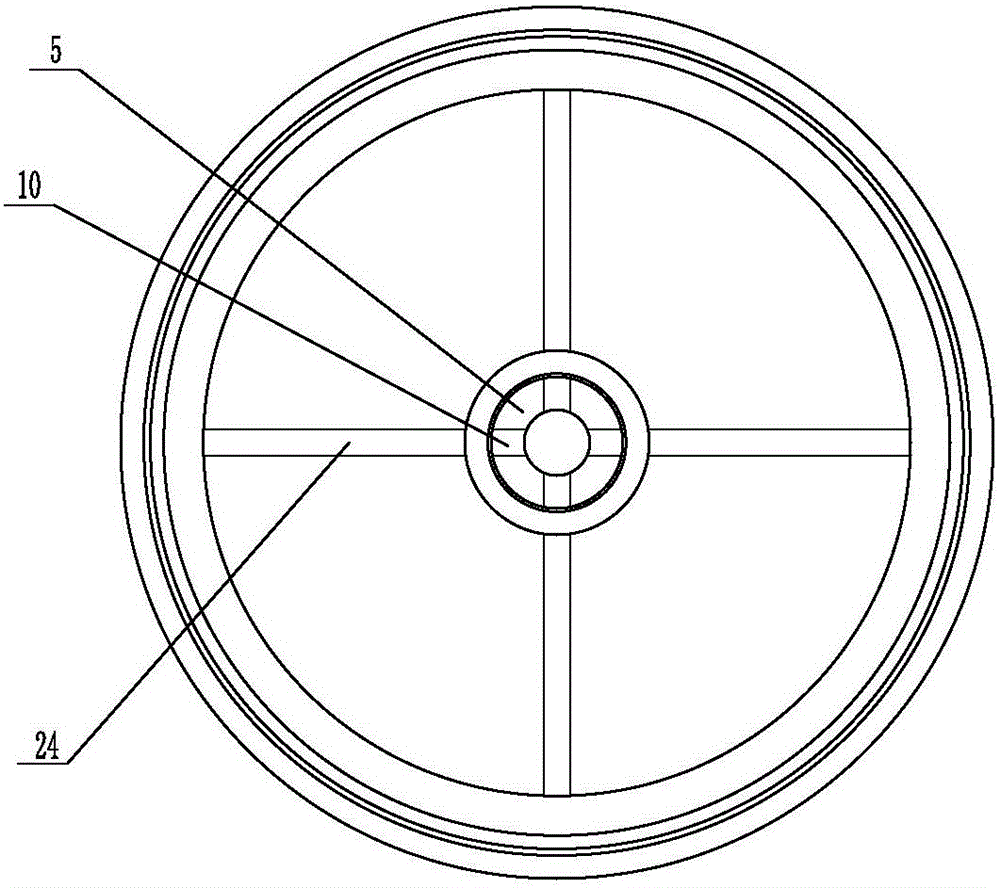

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Shown, a kind of gas filter, it comprises shell 1, and shell 1 is divided into upper shell and lower shell, is convenient to the preparation of shell 1 like this, improves yield, and then reduces production cost, and lower shell and upper shell The casing is connected by riveting, and a sealing ring is provided between the bonding surfaces of the upper casing and the lower casing; the casing 1 is provided with a filter cavity 2, and the upper end of the casing 1 is provided with an outlet 3, and the casing The lower end of 1 is provided with an inlet 4, and the connection between the inlet 4 and the outlet 3 in the filter cavity 2 is respectively provided with a first annular protrusion 5 and a second annular protrusion 6, and the axis of the first annular protrusion 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com