Fixed supporting type negative angle forming die of plates

A fixed support type, sheet metal technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of easy damage, friction damage of sheet metal appearance, poor force of support slider, etc., and achieve safety improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

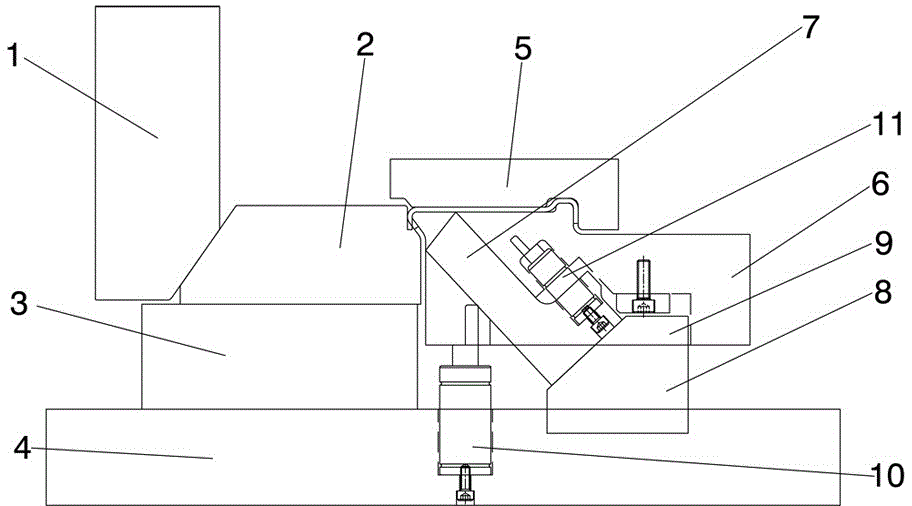

Embodiment

[0016] The dimension of punch 1 is length 100mm*width 77mm*height 150mm; the dimension of horizontal slider 2 is length 120mm*width 150mm*height 61mm; the dimension of backing plate 3 is length 150mm*width 172mm*height 65mm; the dimension of mold base 4 is length 350mm * Width 495mm* Height 60mm; Upper mold pressing block 5 measures length 180mm*Width 142mm*Height 44mm; Lower die pressing block 6 measures length 180mm*Width 202mm*Height 88mm; Support slider 7 measures length 100mm*Width 65mm * height 137mm; top block 8 size is length 100mm * width 88mm * height 73mm; top block space 9 size is length 100mm * width 120mm * height 75mm, the model of nitrogen spring 10 is KALLER brand X350-038, the model of nitrogen spring 11 It is KALLER brand X170-019.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com