End cap for a wiper

A wiper, device technology, applied in the field of assembling such caps, wiping systems, caps on ends, capable of solving the problems of insufficient robustness of the mechanical linkage, detachment, failure to prevent movement of locking devices, etc., to improve overall quality control , increase the level of firmness, and improve the effect of component safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

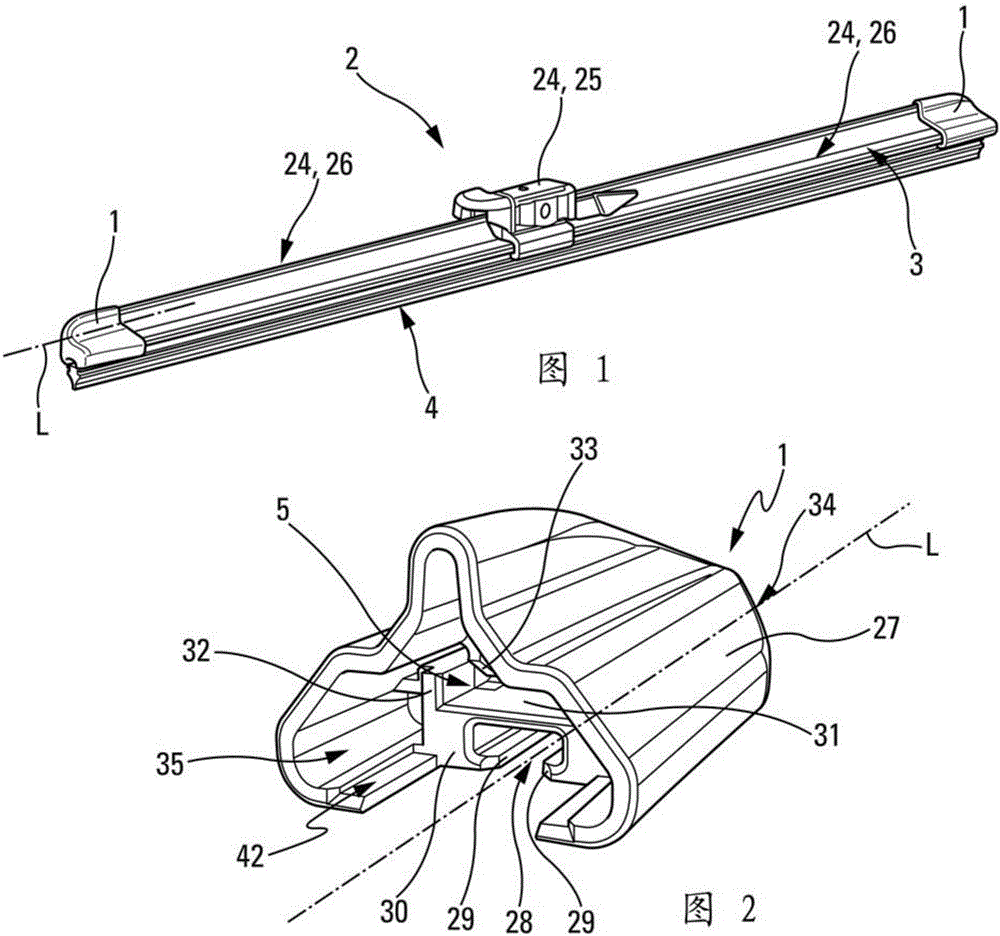

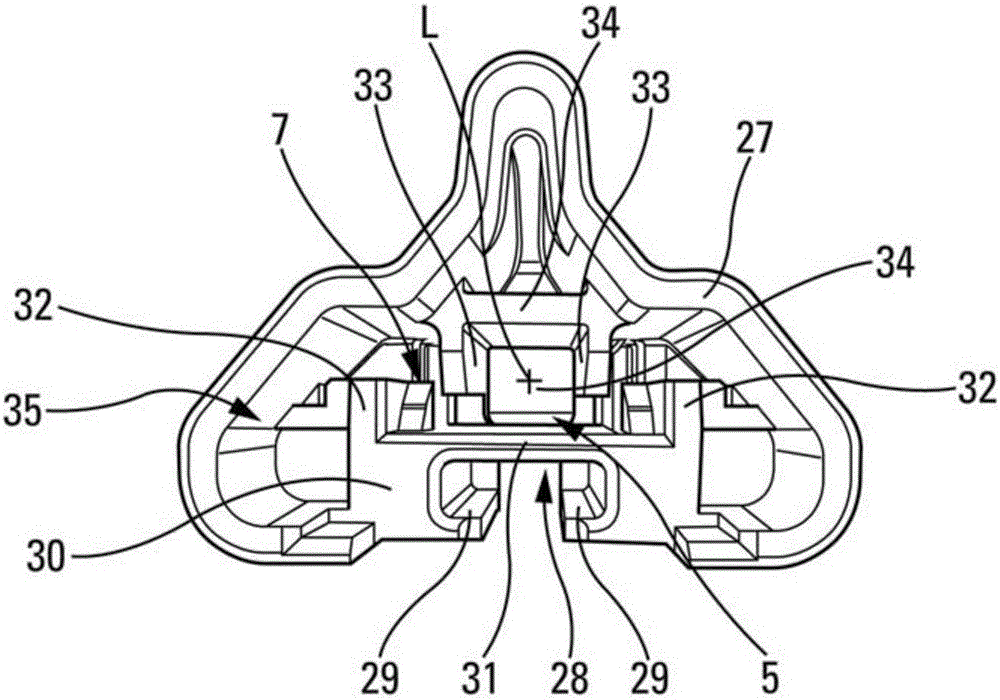

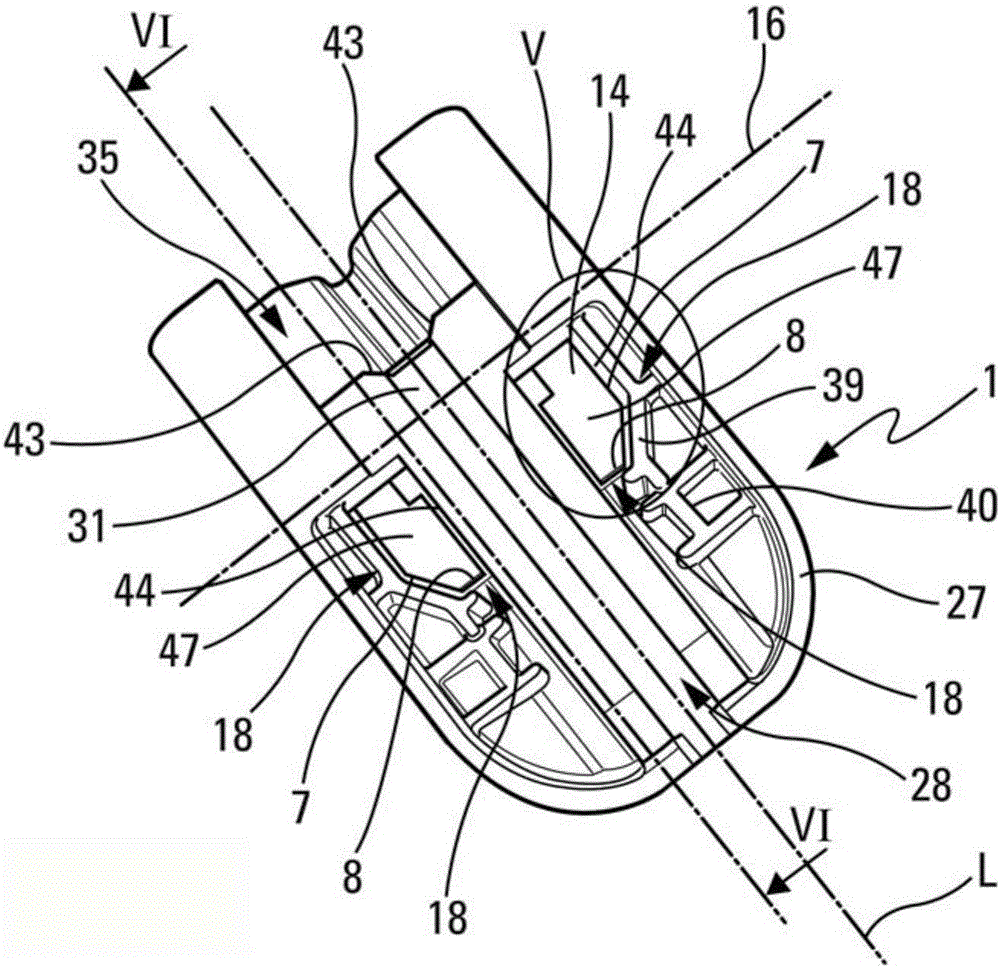

[0042] It should be pointed out at the outset that the accompanying drawings show the invention in detail to allow it to be practiced, and where appropriate these drawings can naturally be used to define the invention.

[0043] In the remainder of the description, the terms longitudinal or lateral, above, below, front and rear shall refer to the orientation of the end cap or wiper according to the invention. The longitudinal direction corresponds to the main axis of the wiper along which the wiper extends, whereas the lateral orientation corresponds to converging straight lines, ie lines straddling the longitudinal direction, in particular perpendicular to the longitudinal axis of the wiper in the plane of rotation of the wiper. For the longitudinal direction, the terms outer or inner are to be understood relative to the point of attachment of the wiper on the rotary drive arm of said wiper, the term inner corresponding to the part where the arm and one wiper half extend. Fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com