A drag reducing device for surface underwater vehicle and preparation method thereof

An underwater vehicle and drag reduction device technology, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of low drag reduction efficiency, high maintenance cost, poor slow release effect of drag reducing agent, etc. The effect of high-efficiency coupling drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing the drag reducing device of the present invention, the flow process of the method is as follows Figure 6 As shown, the specific steps are as follows:

[0040]Step 1: Obtaining the Microscopic Topography of Shark Skin

[0041] Electron microscopy was used to obtain the microscopic morphology of shark skin.

[0042] The second step: the establishment of 3D printing model

[0043] According to the microscopic structure obtained in the first step, a 3D printing model of the shark epidermis microstructure is constructed to prepare for 3D printing.

[0044] Step 3: 3D printing glass to make a high-fidelity shark drag-reducing microstructure main body

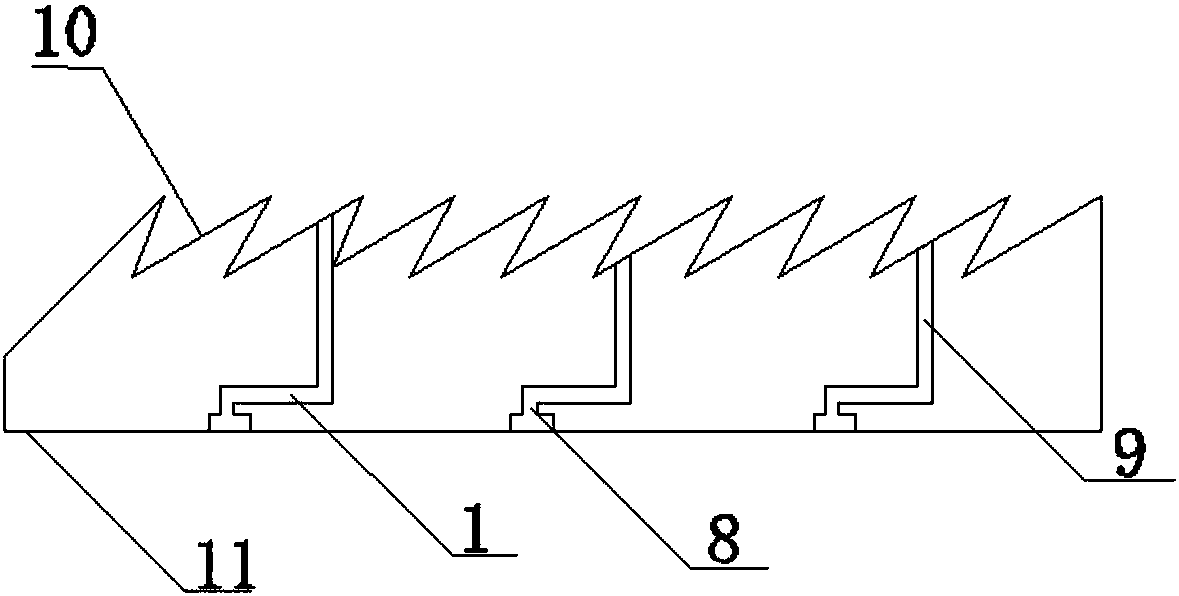

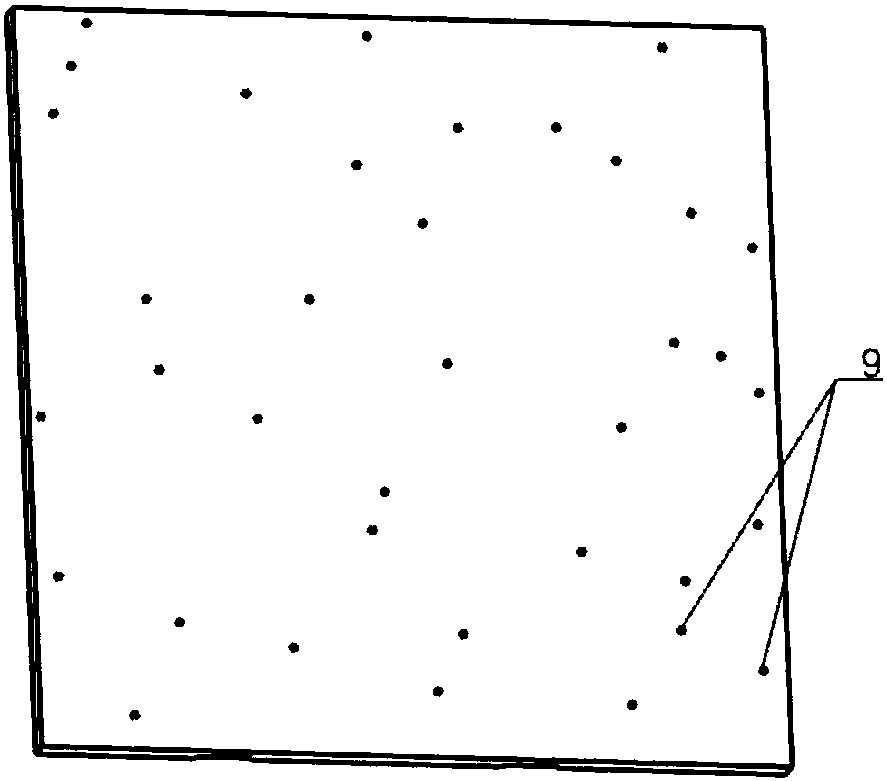

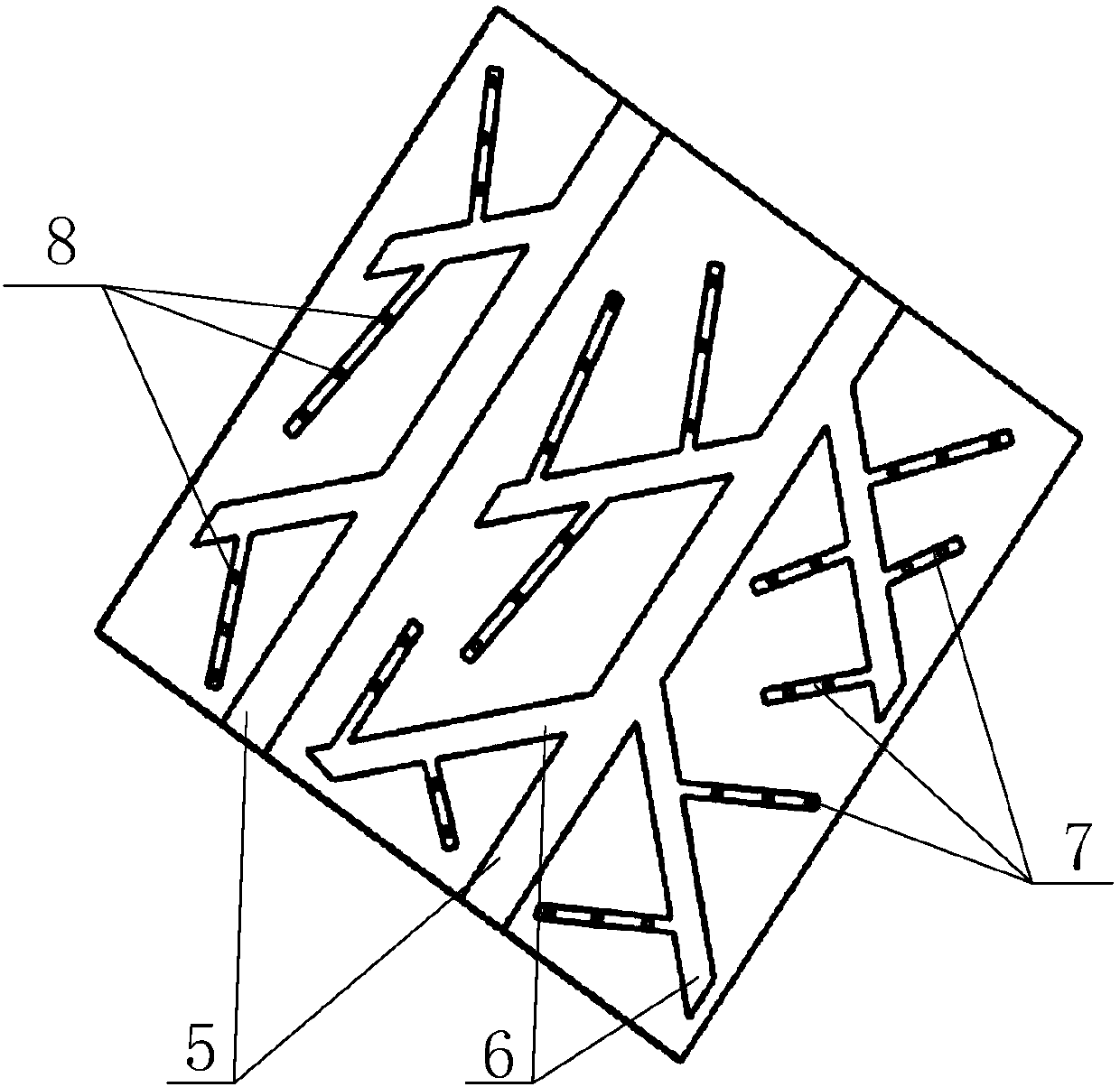

[0045] Using 3D printing technology and glass wire, a shark-like drag-reducing microstructure is produced, and a square structure with a side length of 10cm is produced. The drag-reducing agent channel layer and communicating holes 8 are made on the back of the shark-like drag...

Embodiment 2

[0059] This embodiment provides a method for preparing a drag reducing device, which differs from Embodiment 1 in that:

[0060] The technical parameters of femtosecond laser processing are: wavelength 800nm, power 100mW, processing speed 20μm / s.

[0061] The width of the I-stage channels 5 on the processed support layer 11 is 10 mm, the depth is 2 mm, and the number is 3 per square decimeter. The second level channel 6 has a width of 6mm and a depth of 2mm. 8 articles. The level III channel 7 has a width of 3 mm and a depth of 1.5 mm, and the number of communicating holes 8 is the same as that of the labyrinth flow channels 3 .

[0062] The single sawtooth structure of the labyrinth channel 3 is in the shape of an isosceles triangle with a base length of 0.4 mm, a height of 1.2 mm, and a thickness of 0.8 mm. The length of the labyrinth channel 3 is 10 mm, the width is 1.5 mm, the depth is 0.8 mm, the distance between adjacent saw teeth is 0.1 mm, and the number of saw teet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com