Automatic overturning machine for material box

A technology of automatic inversion and material box, applied in emptying containers, loading/unloading, bottle filling, etc., to achieve the effect of simple operation, reducing the overall height and optimizing the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

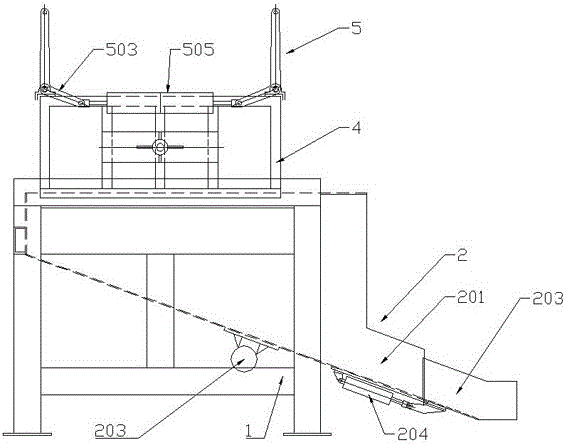

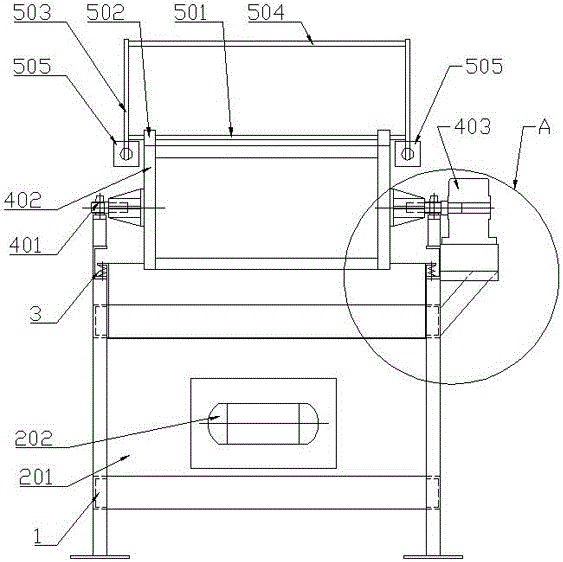

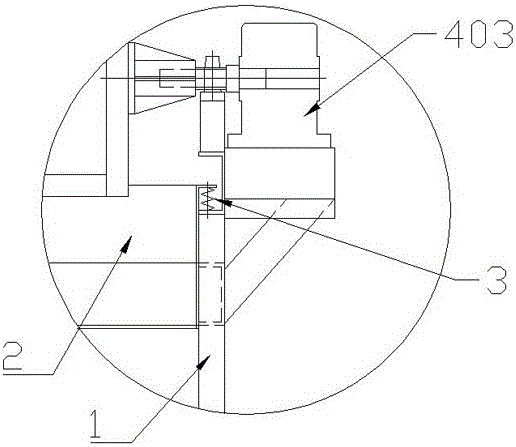

[0014] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a material box automatic turning machine includes a frame 1, which is provided with a tilted collection bucket 2, and the collection bucket 2 is installed on the frame 1 through a shock-absorbing spring 3 and a tension bolt, and the collection bucket 2 An inclination angle of 70 degrees with the horizontal ground; a turning device 4 is provided on the frame 1 corresponding to the inlet of the collecting hopper 2, and a pressing device 5 is provided at the inlet of the turning device 4; the structure of the collecting hopper 2 is : Including the hopper 201, the bottom surface of the hopper 201 is provided with a vibrator 202, the discharge end of the hopper 201 is provided with a telescopic guide slide 203, the guide slide 203 is slidingly matched with the discharge end of the hopper 201, and the bottom surface of the hopper 201 A telescopic cylinder 204 is fixed on the telescopic cylinder 204, the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com