Polycarboxylic acid formaldehyde-free non-ironing fabric whitening liquid and application thereof

A technology of non-ironing fabrics and whitening liquid, which is applied in the direction of bleaching products, etc., can solve the problem of low whiteness improvement value, and achieve the effect of high whiteness improvement value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Whitening process of cationic fluorescent whitening agent by dip dyeing method

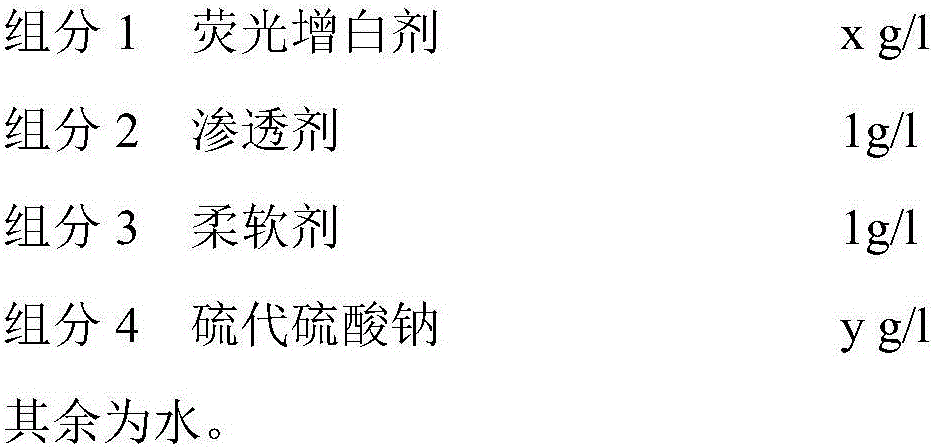

[0036] The whitening solution is made by physically mixing the components of the following concentrations:

[0037] Component 1 Cationic fluorescent whitening agent BAC 1% (o.w.f)

[0038] Component 2 Penetrant JFC 1g / l

[0039] Component 3 polyethylene softener Adalin NI 1g / l

[0040] The rest is water.

[0041] Bath ratio 1:20

[0042] Process flow: adjust the pH of the whitening solution to 3.5 with oxalic acid, bathe the fabric at 40°C, raise the temperature to 95°C for 30 minutes, keep it warm for 35 minutes, wash and dry.

Embodiment 2

[0044] Pad-steam whitening process of cationic fluorescent whitening agent

[0045] The whitening solution is made by physically mixing the components of the following concentrations:

[0046] Component 1 Cationic fluorescent whitening agent BAC 1.25g / l

[0047] Component 2 Penetrant JFC 1g / l

[0048] Component 3 Silicone Softener SIE 1g / l

[0049] The rest is water.

[0050] Technological process: adjust the pH value of the finishing solution to 4.0 with formic acid, dipping and rolling twice (rolling rate: 80%), steaming (102°C×20min, humidity: 40-45%), washing and drying.

Embodiment 3

[0052] Whitening process of cationic fluorescent whitening agent by padding-drying method

[0053] The whitening solution is made by physically mixing the components of the following concentrations:

[0054] Component 1 Cationic fluorescent whitening agent BAC 1.25g / l

[0055] Component 2 Penetrant JFC 1g / l

[0056] Component 3 polyethylene softener Adalin NI 1g / l

[0057] The rest is water.

[0058] Technological process: adjust the pH of the finishing solution to about 3.5 with oxalic acid, dip twice and roll twice (surplus rate: 80%), and dry with hot air (110°C×2min).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com