High current rotary indoor high voltage isolating switch

An isolating switch and rotary technology, applied in electrical switches, high-voltage air circuit breakers, air switch parts, etc., can solve the problems of decreased electrical conductivity, heat of contact fingers and bases, and increased temperature rise of high-voltage isolating switches. Kinetic thermal stability, good electrical conductivity, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

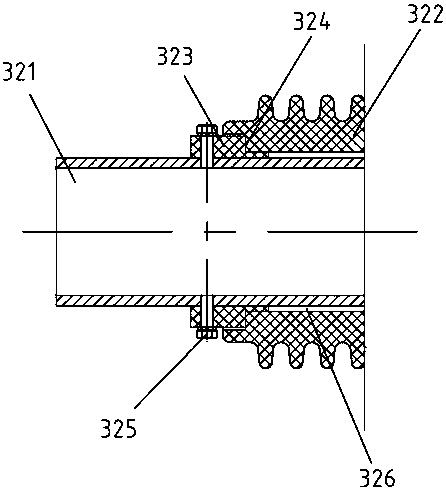

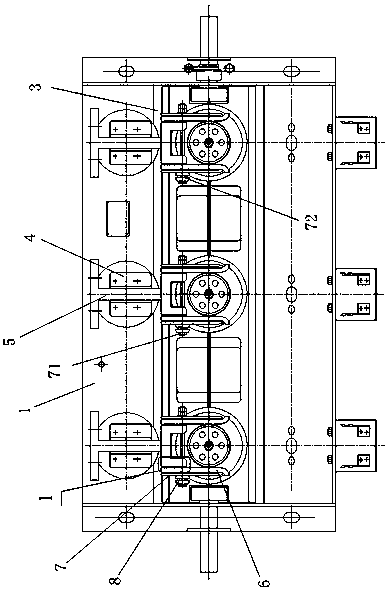

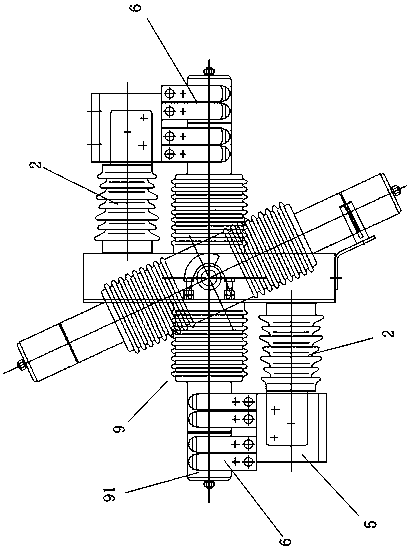

[0019] Such as Figure 4 As shown, the present invention includes a stainless steel chassis 10, an aluminum clip 20 and a three-phase conductive unit 30, the stainless steel chassis 10 is vertically arranged, the three-phase conductive units 30 are arranged side by side on the stainless steel chassis 10, the aluminum clip 20 is arc-shaped, and the In the middle of the three-phase conduction unit 30 . Such as Figure 5 As shown, each phase conductive unit 30 includes two contact seats 31, a bushing 32 with a conductive tube 321 and two sets of contact pieces 33. The two sets of contact pieces 33 are respectively located at the upper and lower parts of the left and right sides of the stainless steel chassis 10. And the openings correspond to the positions of the two ends of the conductive tube 321 one by one.

[0020] Such as Figure 4 As shown, the contact seat 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com