Broadband wave absorbing material with stable polarization

A wave-absorbing material and broadband technology, applied in the fields of wave-absorbing material, antenna communication and absorption shielding, can solve the problems of insufficient low-frequency bandwidth and poor polarization stability, so as to widen the working bandwidth, realize absorption and shielding, and enhance absorption and shielding. The effect of the wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

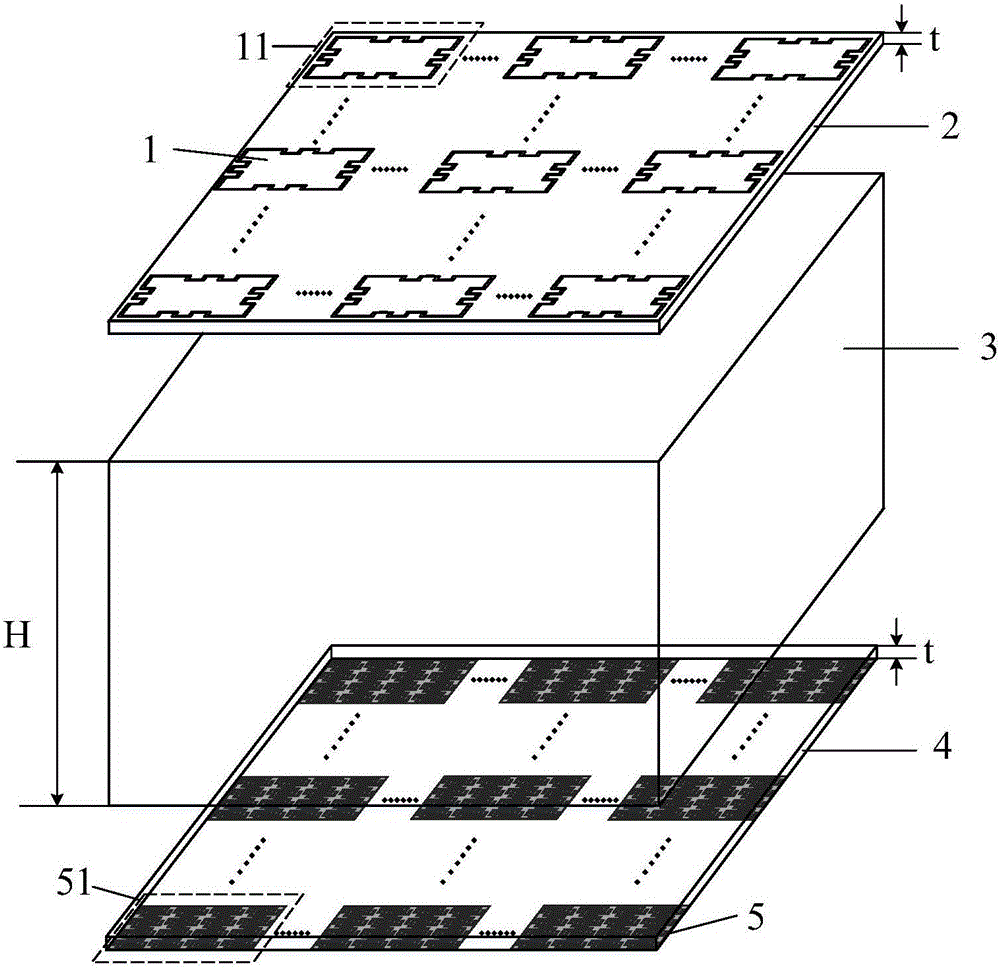

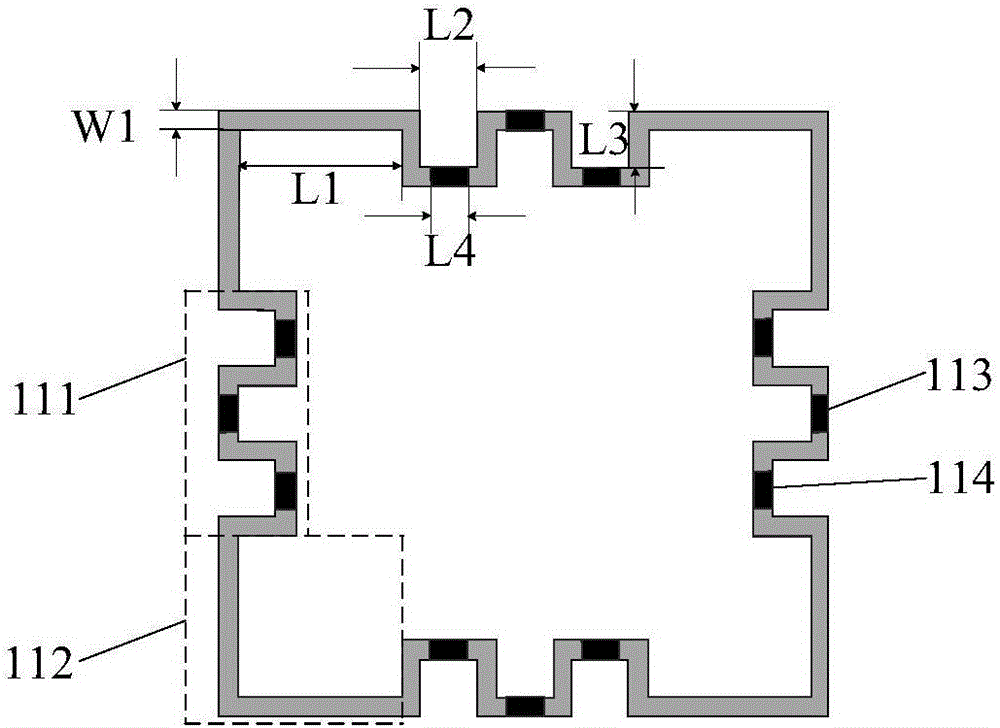

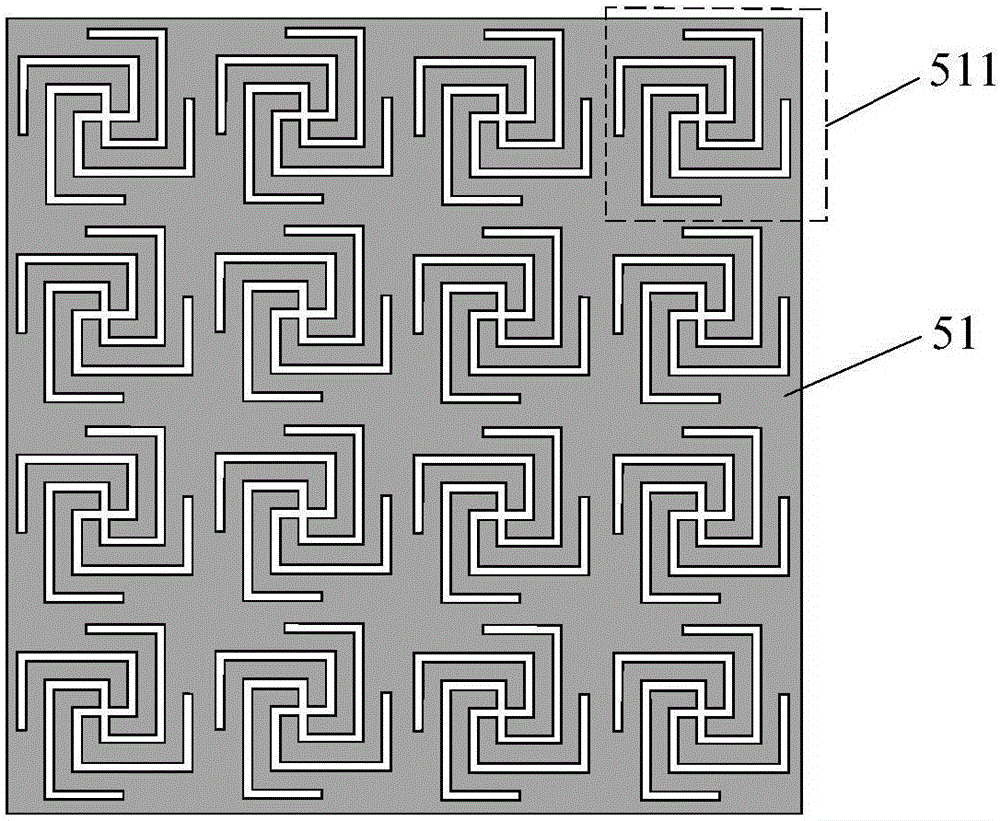

[0026] refer to figure 1 , the present invention includes a wave-absorbing structure 1, an upper dielectric plate 2, a foam layer 3, a lower dielectric plate 4 and a frequency selective surface 5; the wave-absorbing structure 1 is printed on the upper surface of the upper dielectric plate 2, and it The geometric center of the upper surface coincides; the frequency selective surface 5 is printed on the lower surface of the lower dielectric plate 4, and it coincides with the geometric center of the lower surface of the lower dielectric plate 4; the upper dielectric plate 2, the foam layer 3 and the lower dielectric plate 4 Arranged in order to form an up and down stacked structure, and the edges of the upper dielectric plate 2, the foam layer 3 and the lower dielectric plate 4 coincide with each other; the absorbing structure 1 is formed by periodic arrangement of M×N quasi-square metal folding line units 11, The frequency selective surface 5 is formed by periodic arrangement of...

Embodiment 2

[0030] The structure of embodiment 2 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0031] The arrangement periods of the metal fold line unit 11 and the frequency selective surface unit 51 are both 17 mm; the upper dielectric plate 2, the foam layer 3 and the lower dielectric plate 4 are all square plates with a side length of 170 mm, wherein the upper dielectric plate 2 and the lower dielectric plate The thickness of 4 is t=0.2mm, and the relative dielectric constant is 2.25; the metal line width W1=0.5mm of the metal folding line unit 11; the length of both arms of the equal-arm "L" type metal folding line 112 is L1=4.3mm; The width of the two grooves of the "bow"-shaped metal fold line 111 with a gap is L2=1.5mm, and the length of the gap is L4=1mm; the resistance value of the eight second chip resistors 114 is 40 ohms; the word "一" The edge distance S1 between the shaped groove 5112 and the folded line groove unit 511 is 0.22...

Embodiment 3

[0032] The structure of embodiment 3 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0033] The arrangement periods of the metal fold line unit 11 and the frequency selective surface unit 51 are both 16.2 mm; the upper dielectric plate 2, the foam layer 3 and the lower dielectric plate 4 are all square plates with a side length of 162 mm, wherein the upper dielectric plate 2 and the lower dielectric plate The thickness of plate 4 is t=0.2mm, and relative dielectric constant is 2.65; Foam layer 3 thickness H=15mm; The metal line width W1=0.5mm of metal folding line unit 11; The length of the arm is L1=4mm; the width of the two grooves of the "bow"-shaped metal fold line 111 with the gap is L2=1.5mm, and the length of the gap is L4=1mm; the resistance value of the eight second chip resistors 114 is 40 ohms; the distance S1 between the "one"-shaped slot 5112 and the edge of the folded line slot unit 511 is 0.125 mm.

[0034] Below in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com