Tubular busbar connection structure

A technology for connecting structure and tube busbar, applied in the direction of connection, connecting contact material, clamping/spring connection, etc., can solve the problems of multiple elastic contact fingers, elastic contact finger damage, unfavorable tube busbar sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

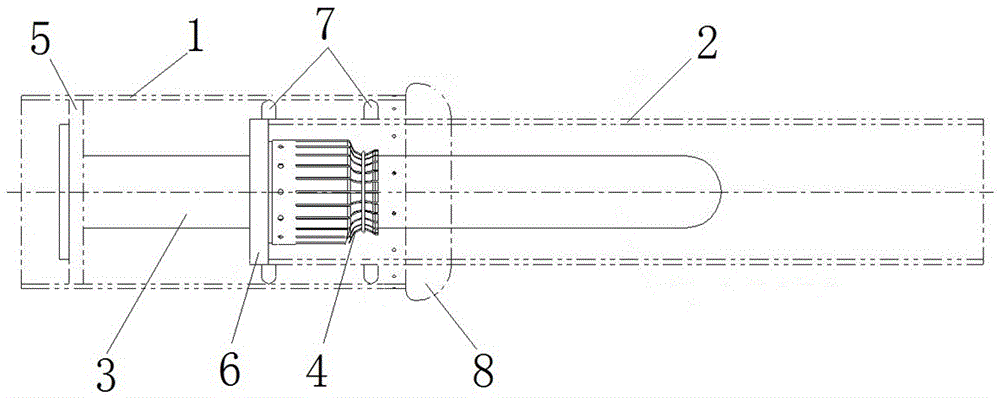

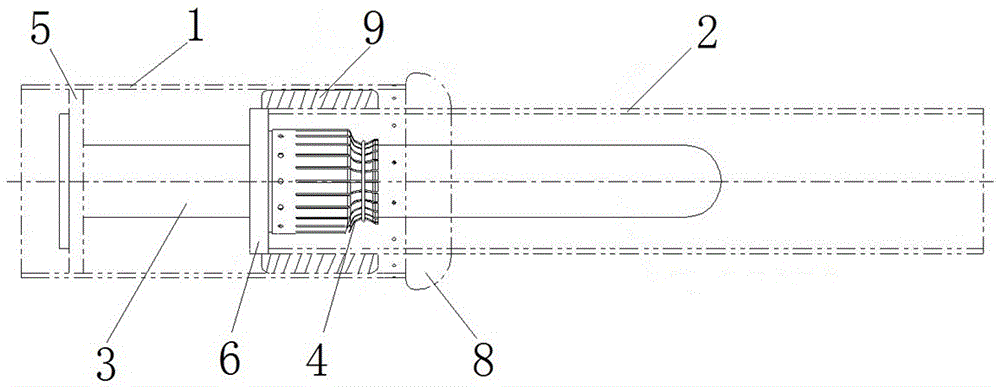

[0018] Specific embodiment 1 of the pipe-female connection fittings of the present invention, such as figure 1 As shown, among them, 1 is the thick tube busbar, 2 is the thin tube busbar, 3 is the contact, 4 is the spring contact finger, 5 is the aluminum terminal board, 6 is the contact seat, 7 is the limit wear-resistant slip ring, 8 is the End cap shield.

[0019] The thin-tube busbar 2 is inserted into the thick-tube busbar 1, and one end of the thin-tube busbar 2 is located in the thick-tube busbar 1, and the two can perform relative plugging and telescopic movements. There is an aluminum terminal board 5 inside the thick tube bus 1 far away from the thin tube bus 2. The aluminum terminal board 5 is arranged in the radial direction of the thick tube bus 1 and conducts with the thick tube bus 1. The contact 3 is installed on the aluminum terminal bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com