Electric Actuator

A technology of electric actuators and sliding mechanisms, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of high on-site adjustment costs, inability to realize automatic adjustment and quantitative adjustment, inability to facilitate unattended adjustment, etc., to achieve relatively Reduce labor costs, eliminate gaps, and accurately and quickly control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

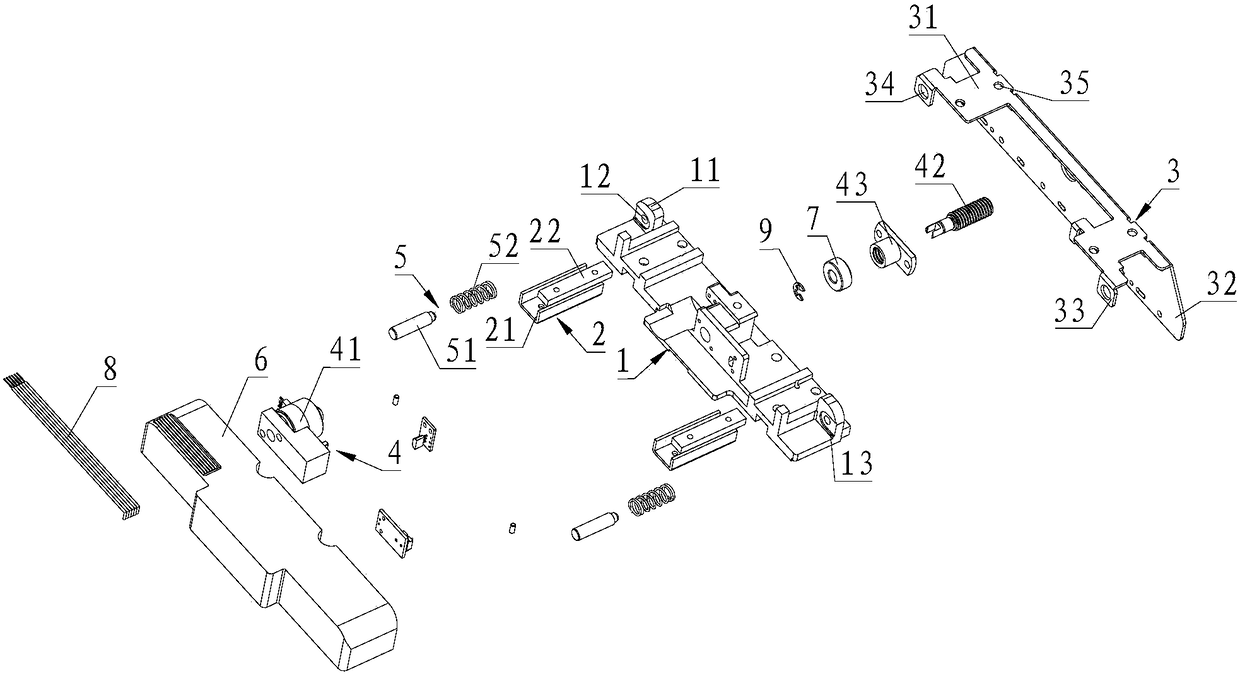

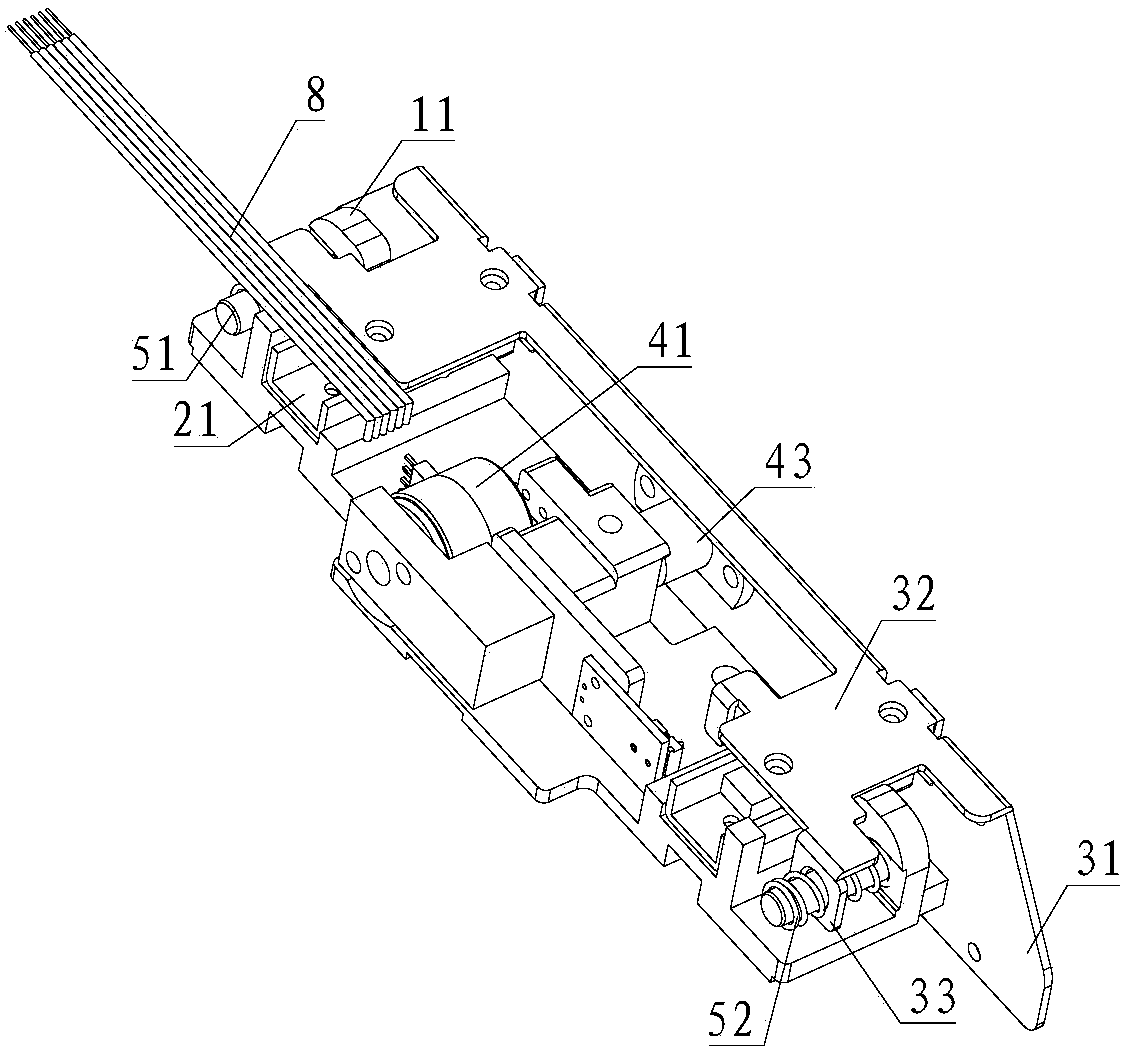

[0015] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0016] The most critical idea of the present invention is: the present invention utilizes the output power of the electric drive mechanism 4 to promote the displacement of the displacement plate 3, and at the same time realizes the stable and accurate displacement of the displacement plate 3 through the sliding mechanism 2 and the spring assembly 5.

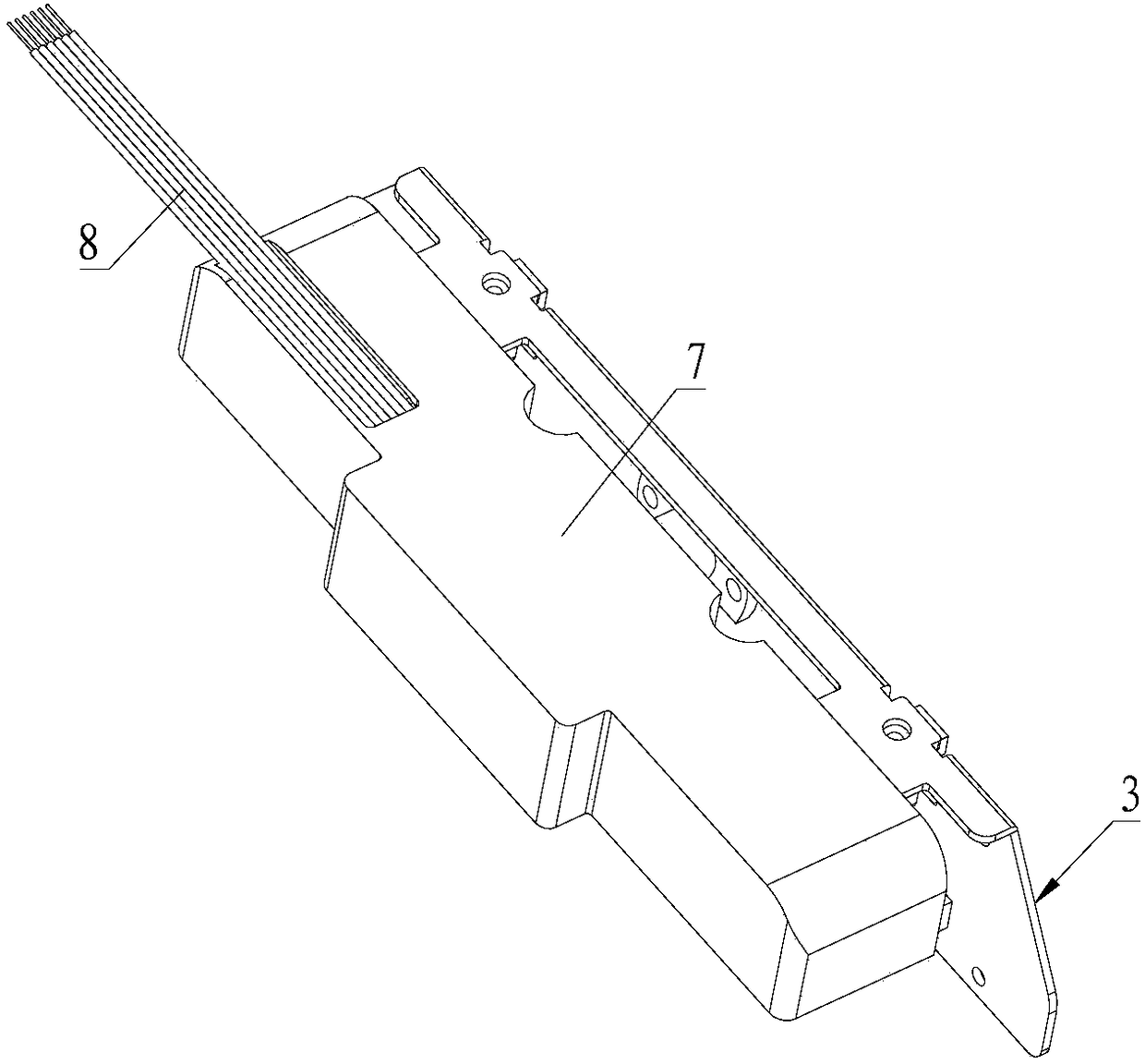

[0017] see Figure 1 to Figure 4 , the electric actuator of the present invention includes a fixed seat 1, a sliding mechanism 2 arranged on the fixed seat 1, a displacement plate 3 arranged on the sliding mechanism 2, an electric drive that connects the displacement plate 3 and drives the displacement plate 3 Agency 4,

[0018] Also includes a spring assembly 5, the spring assembly 5 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com