Terminal and aluminum wire connection structure of terminal

A technology of aluminum wires and terminals, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of easy corrosion deepening and corrosion, and achieve the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

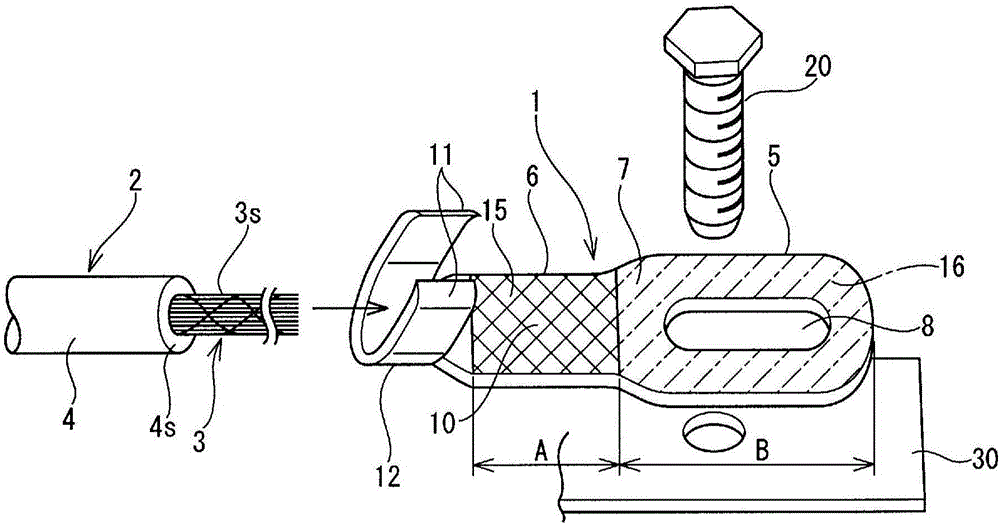

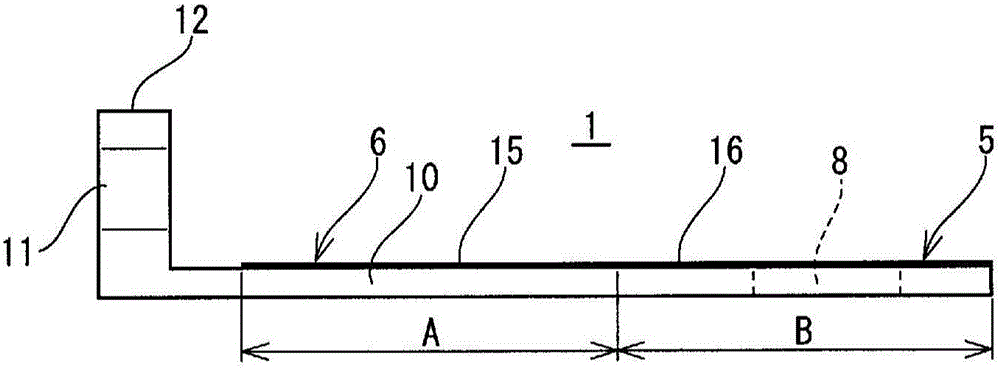

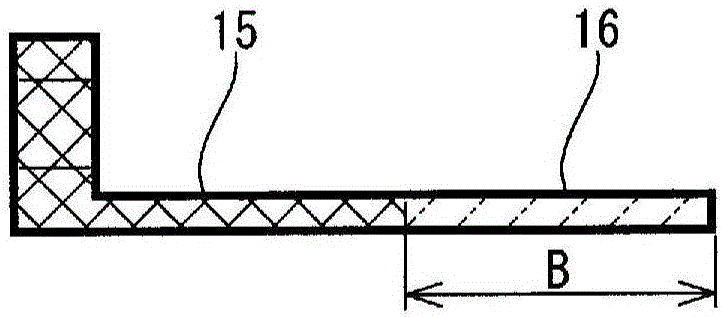

[0049] Figure 1 to Figure 4 Terminals of the first embodiment are shown.

[0050] The terminals consist of screw fastening terminals 1, such as figure 1 As shown, it is connected to the end of an aluminum electric wire 2 obtained by covering an aluminum core wire 3 obtained by twisting an aluminum-based metal wire 3s with an insulating coating 4 made of insulating resin. The aluminum electric wire 2 of this embodiment is that the cross-sectional area of the aluminum core wire 3 is 8mm 2 The above-mentioned thick electric wires are arranged in automobiles as power lines or grounding lines.

[0051] The screw fastening terminal 1 is provided with an electrical contact portion 5 at the front and with a wire connection portion 6 at the rear. Specifically, the front portion of the substrate 7 extending in the front-rear direction is formed wide to form the electrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com