A method for evaluating the health degree of an automatic verification assembly line for electric energy meters

An automatic verification and evaluation method technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve problems such as not considering the degree of importance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

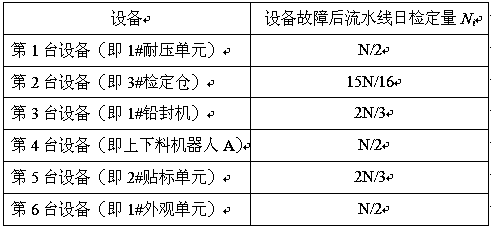

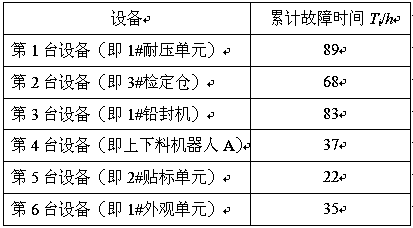

[0032] The assembly line composed of 6 equipments, the equipment failure records within one year are shown in Table 1. Table 1 shows the repair time of each fault of the faulty equipment, and this table does not show the faulty equipment.

[0033] Table 1 Equipment failure records

[0034]

[0035] From Table 1, the number of failures of the 1st to 6th equipment can be obtained, as shown in Table 2.

[0036] Table 2 The number of failures of the 1st to 6th equipment

[0037]

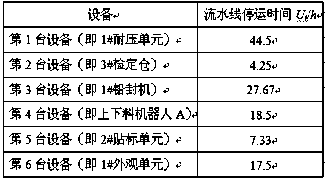

[0038] After the 1st to 6th equipment fails respectively, the daily inspection quantity of the assembly line is shown in Table 3.

[0039] Table 3 Daily inspection quantity of assembly line after equipment failure

[0040]

[0041] The health degree of the above-mentioned assembly line equipment is verified according to a method for evaluating the health degree of the automatic verification assembly line of electric energy meters as follows:

[0042] Step 1: Use the formula (1) to calculate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com