Fastening element for a current sensor

A technology of current sensors and fixed components, applied in the direction of inductors, electrical components, only measuring current, etc., can solve problems such as manual work, installation complexity, screw loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

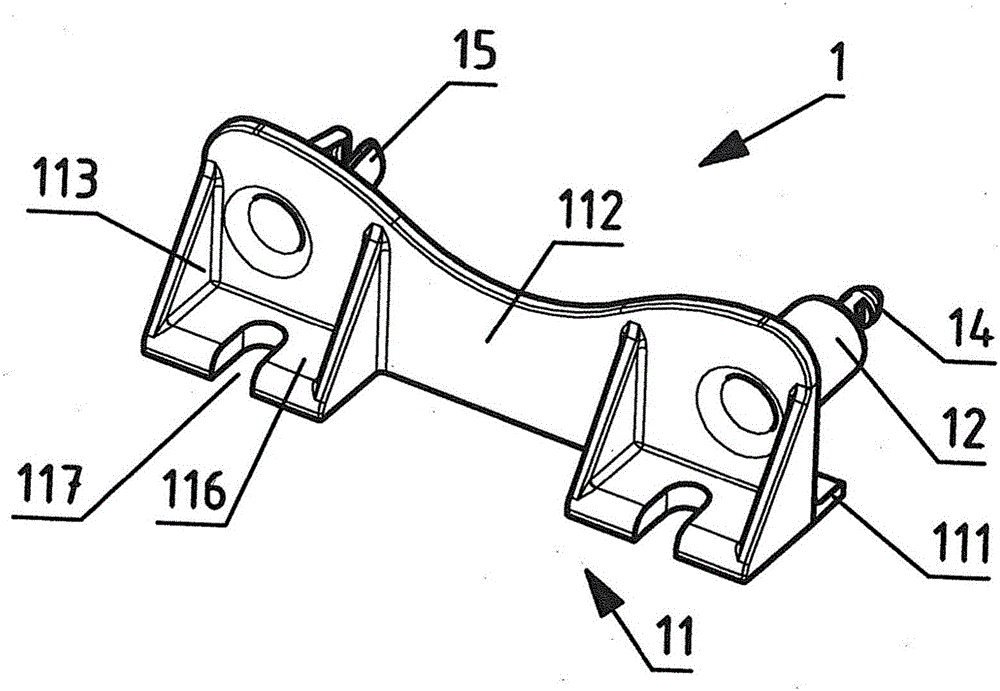

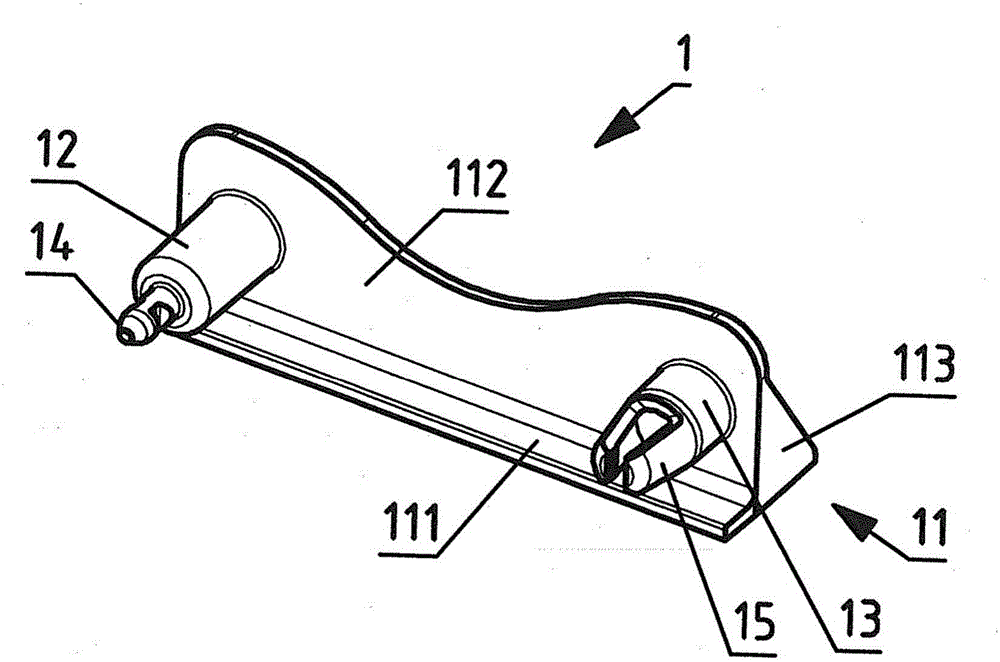

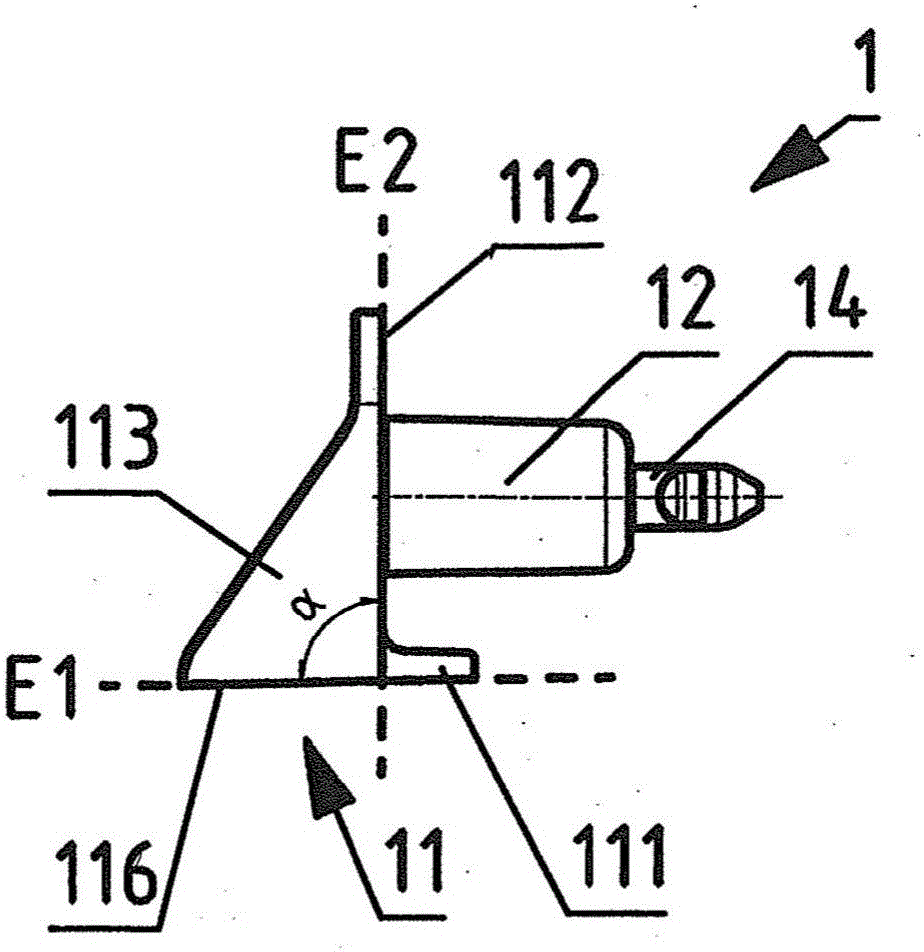

[0041] Figure 1a , 1b , 1c and 1d show different views of the fixing element 1 . The fastening element has a flange area 11 and two latching means, namely a first latching means and a second latching means.

[0042] The flange region 11 is clearly visible in FIG. 1 . This flange area has a seat area for fastening to the fastening surface 3 . This bearing area has bearing slats 111 and two bearing surfaces 116, in Figure 1b The support strips are again clearly visible. Fastening notches 117 can be arranged in each such seat surface 116 , for example for screwing or otherwise fastening to the fastening surface 3 . Advantageously, the flange area 11 has a clamping surface 112 . The support strip 111 , the two support surfaces 116 and the clamping surface 112 adjoin one another and are also connected to one another by a stabilizing surface 113 in order to stabilize their fastening to one another. Each of the two abutment surfaces 116 is connected to the clamping surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com