Automatic stuffing chopping machine and automatic stuffing chopping method

An automatic and filling technology, applied in the field of kitchen utensils, can solve problems such as affecting the original taste of meat or vegetables, achieve good social benefits and market prospects, and save energy and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

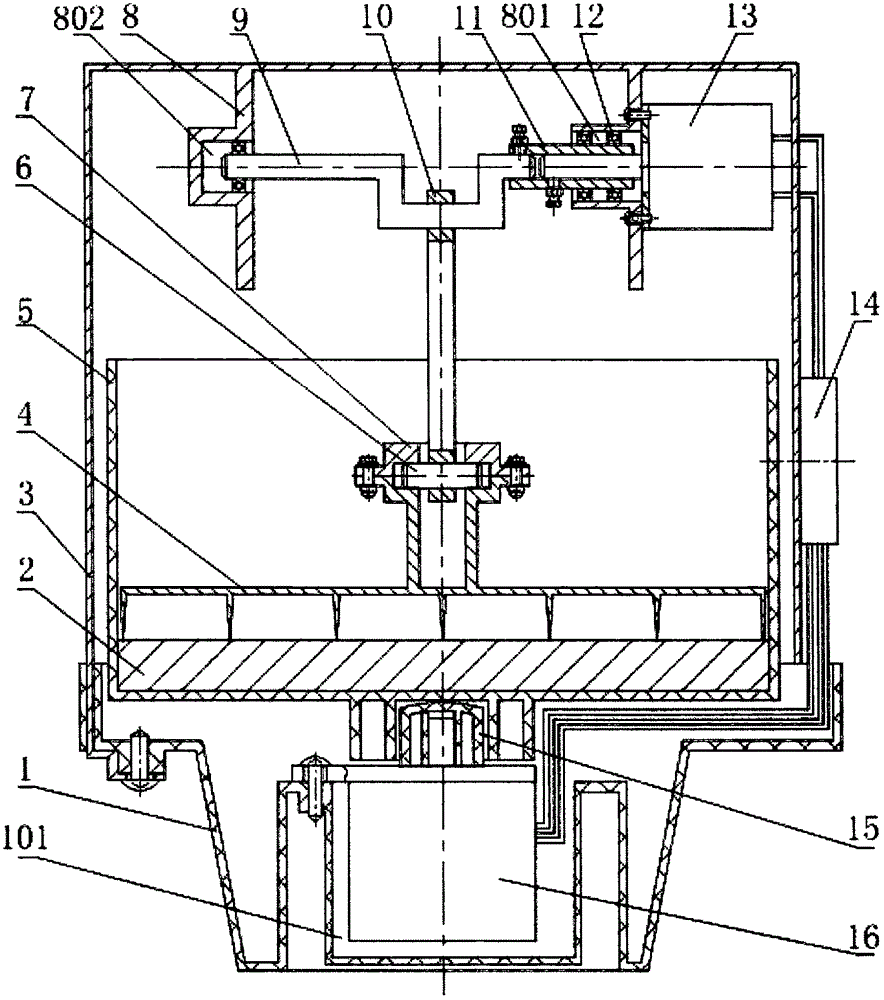

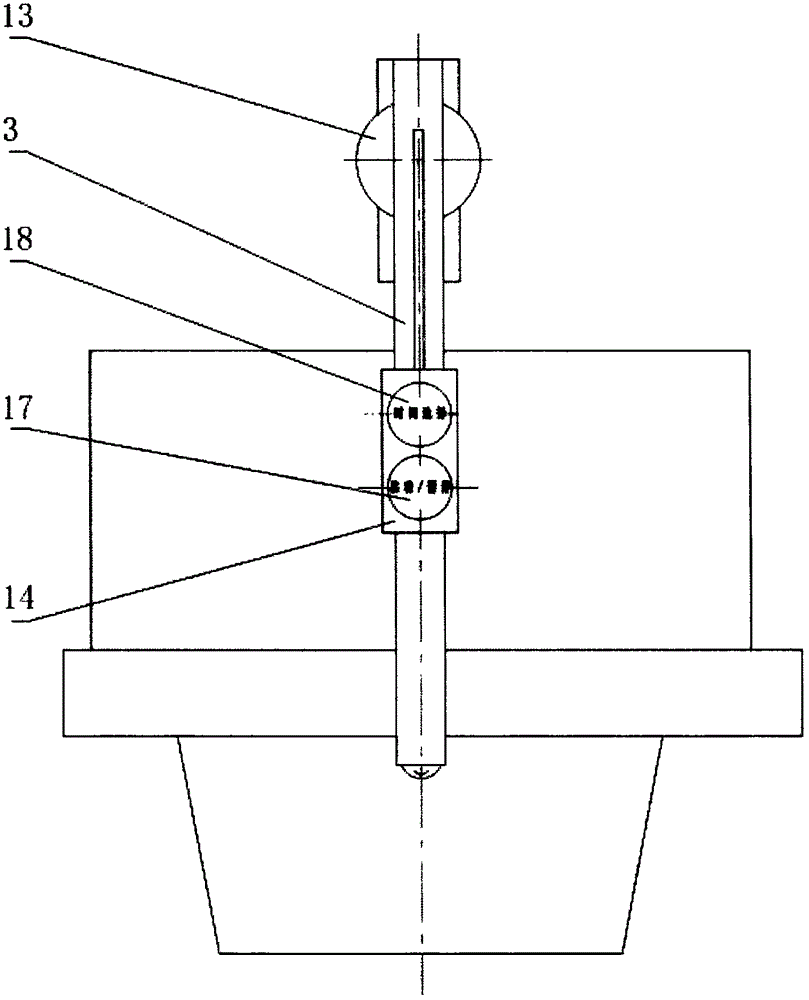

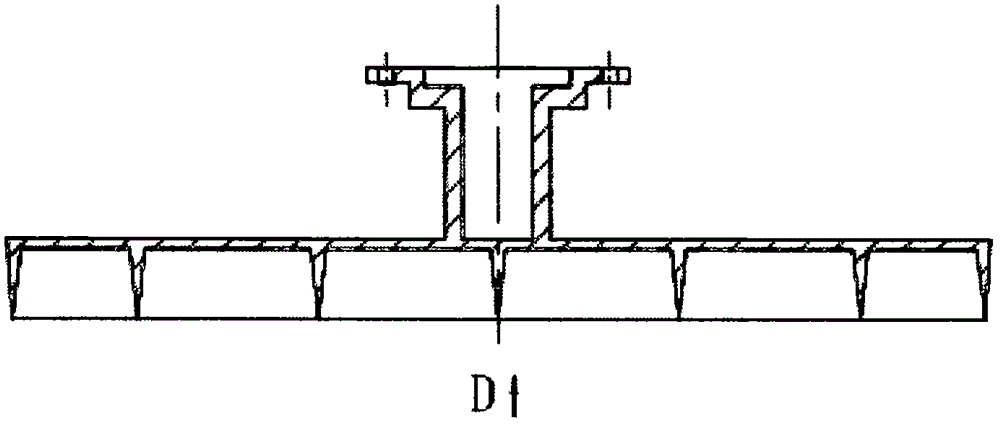

[0033] Such as Figure 1 to Figure 2 As shown, the automatic filling machine of the present invention mainly includes a base 1 and a mounting frame 3 fixed on the base 1. There is a groove 101 in the middle of the base 1, and a step motor combination is fixedly installed in the groove 101 in the middle of the base 1. There is a pair of vertical frames 8 in the middle of the mounting frame 3, and a combination of stuffing chopping is installed on a pair of vertical frames 8, and a container combination is set on the upper part of the stepping motor combination; The shaft device 11 and the filling mechanism are composed, the coupling 11 is fixedly installed in the inner concave cylindrical groove 801 of a vertical frame 8 through the bearing 12, and the stuffing chopping motor 13 is fixedly installed on a vertical frame 8 of the sleeve coupling 11, The motor shaft is fixedly set in the shaft hole of the coupling 11. The stuffing chopping mechanism includes a crank 9, a cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com