A powder coating thermosetting equipment

A powder coating and equipment technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem of not meeting modern technology, and achieve the effect of increasing adhesion, saving heating time, and increasing hot melt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

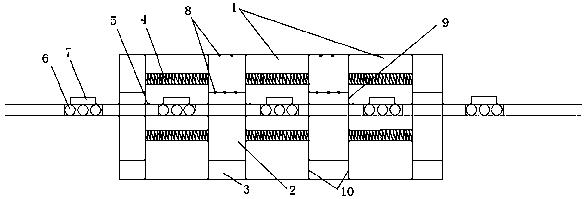

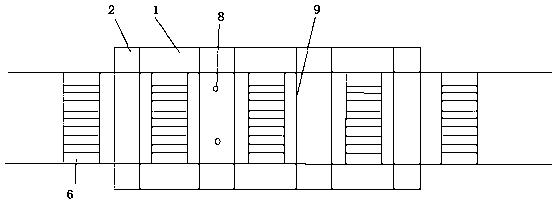

[0018] A kind of thermosetting equipment for powder coating, in which several thermosetting units 1 are arranged in the box, compartments are arranged between thermosetting units 1, and thermosetting units 1 communicate with compartments through compartment doors 9; thermosetting units 1 are equipped with There are 6 roller shafts and heating pipes 4, and the heating pipes 4 are arranged on the top and bottom of the 6 roller shafts.

[0019] The compartments include an upper compartment 2 and a lower compartment 3, and the upper compartment 2 and the lower compartment 3 are not communicated with each other.

[0020] A ventilation door 10 is provided between the bottom of the thermosetting unit 1 and the lower compartment 3 . When the workpiece 7 is transported from the low-temperature thermosetting unit 1 to the high-temperature thermose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com