Coil core patting and aligning device

A technology for a snapping device and a core, which is applied to the field of a core snapping device, can solve the problems of coiling affecting transportation and hoisting, inability to beat the steel coil, and the height of the collision plate is not adjustable, and achieves significant beneficial effects and scope of application. Wide range of effects suitable for application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

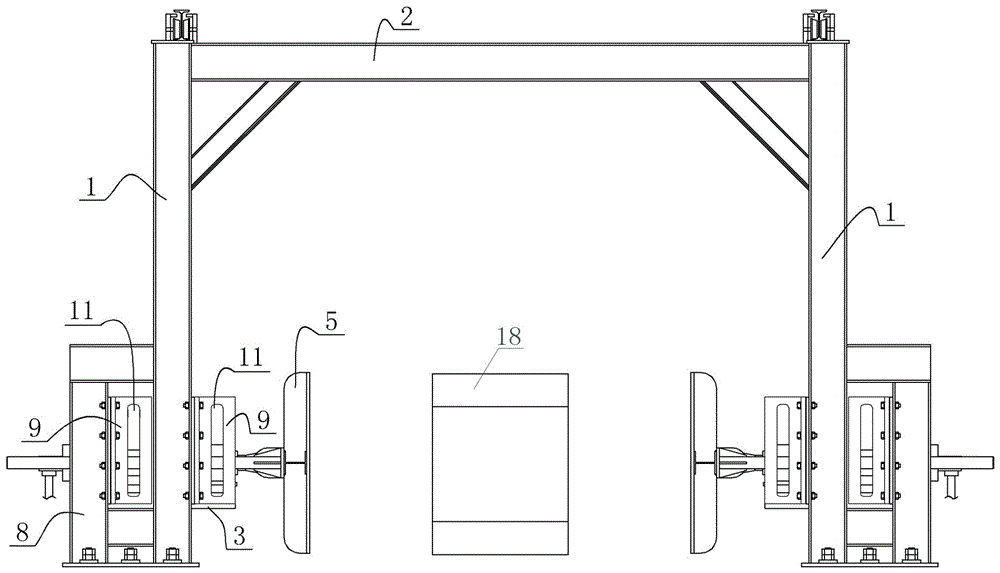

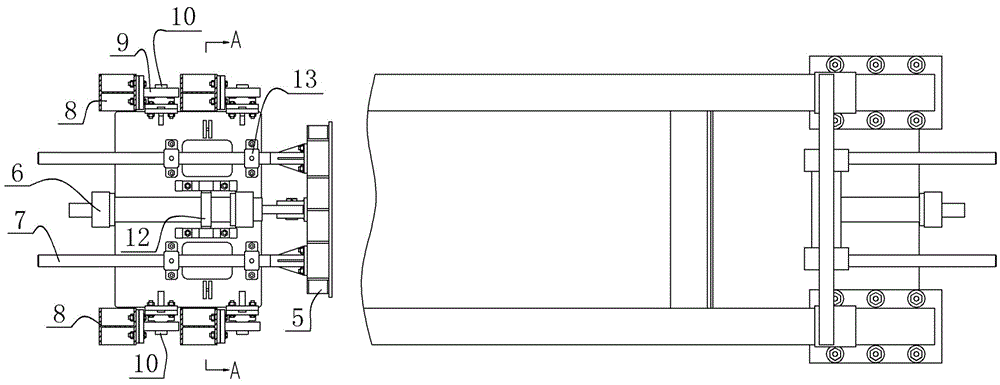

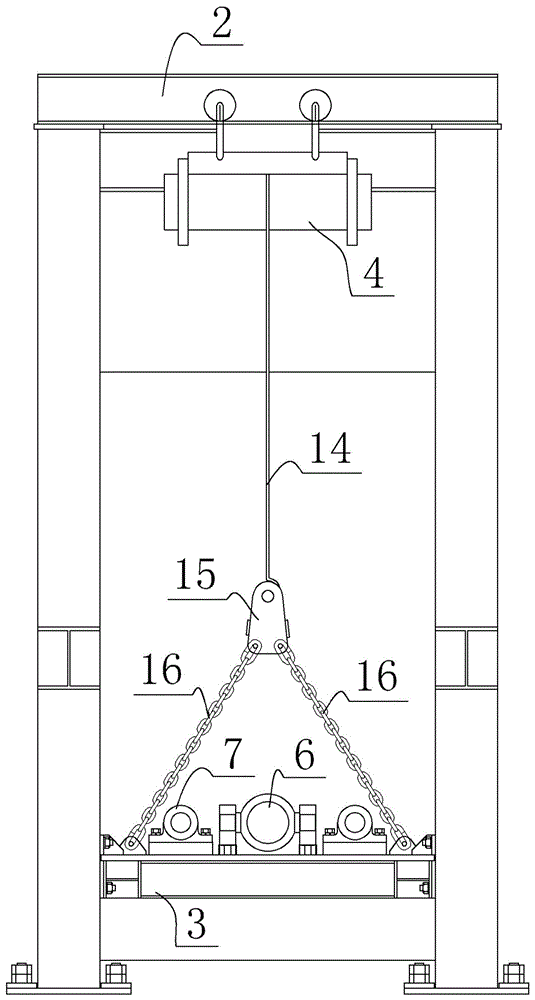

[0020] Such as figure 1 , figure 2 and image 3 As shown, the front view, top view and left side view of the winding core alignment device of the present invention are provided respectively, and the winding core alignment device of the present invention shown in the figure is composed of a vertical beam 1, a cross beam 2, an elevating platform 3, and a driving motor 4 , clapping hands 5, hydraulic cylinder 6, guide rod 7, guide rail 9, steel wire rope 14, connecting plate 15, chain 16, vertical beam 1 and cross beam 2 form the frame, and the left and right sides are provided with two vertical beams 1, The crossbeam 2 is fixed on the top of the vertical beam 1, and the left and right sides of the frame are all provided with an elevating type clapping mechanism, and the elevating type clapping mechanism is composed of a lifting table 3, a driving motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com