Application method of turning bed measurement data based on train wheelset online monitoring system

A monitoring system and measurement data technology, applied in measurement/indication equipment, metal processing equipment, metal processing machinery parts, etc. The effect of using reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

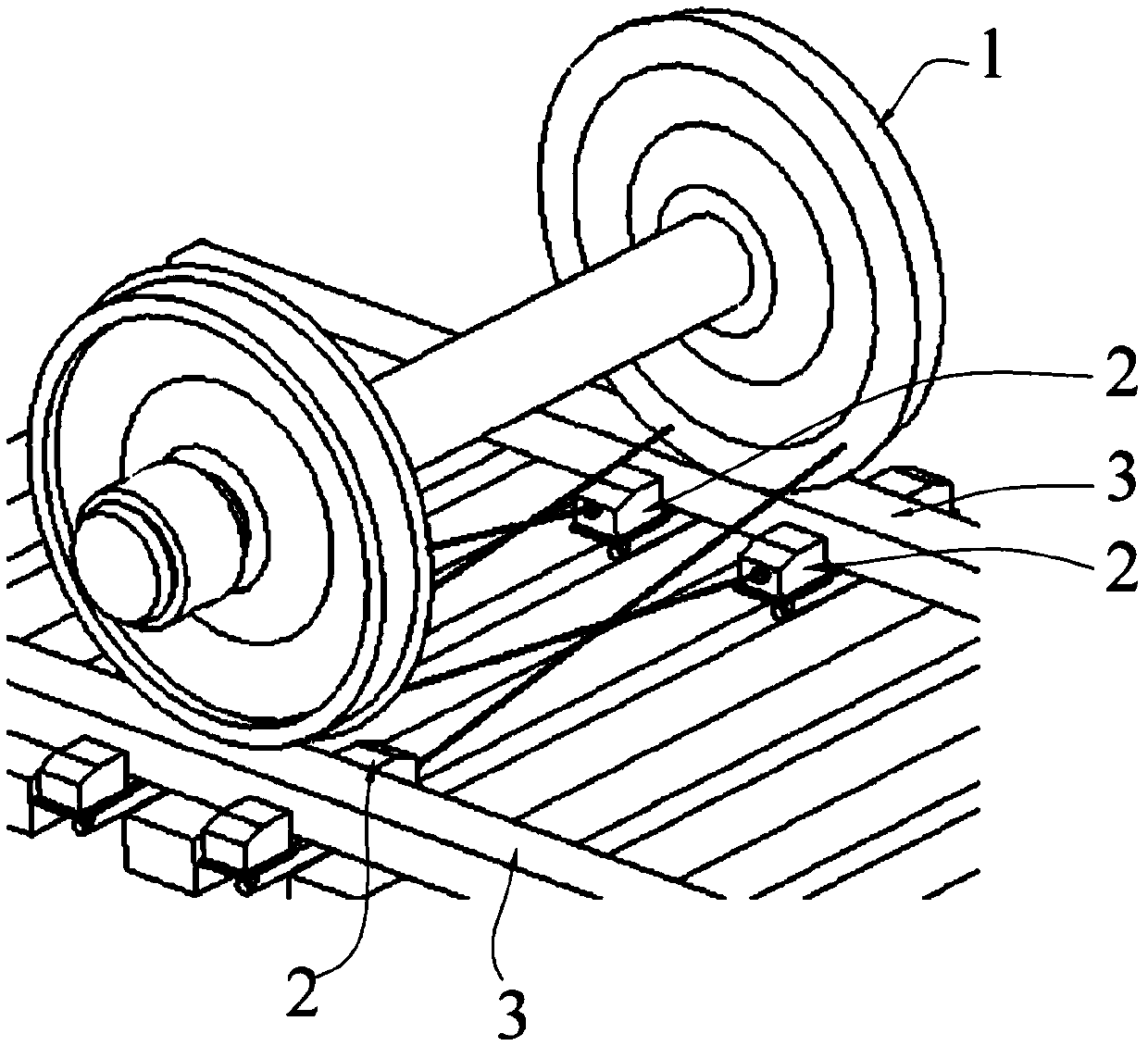

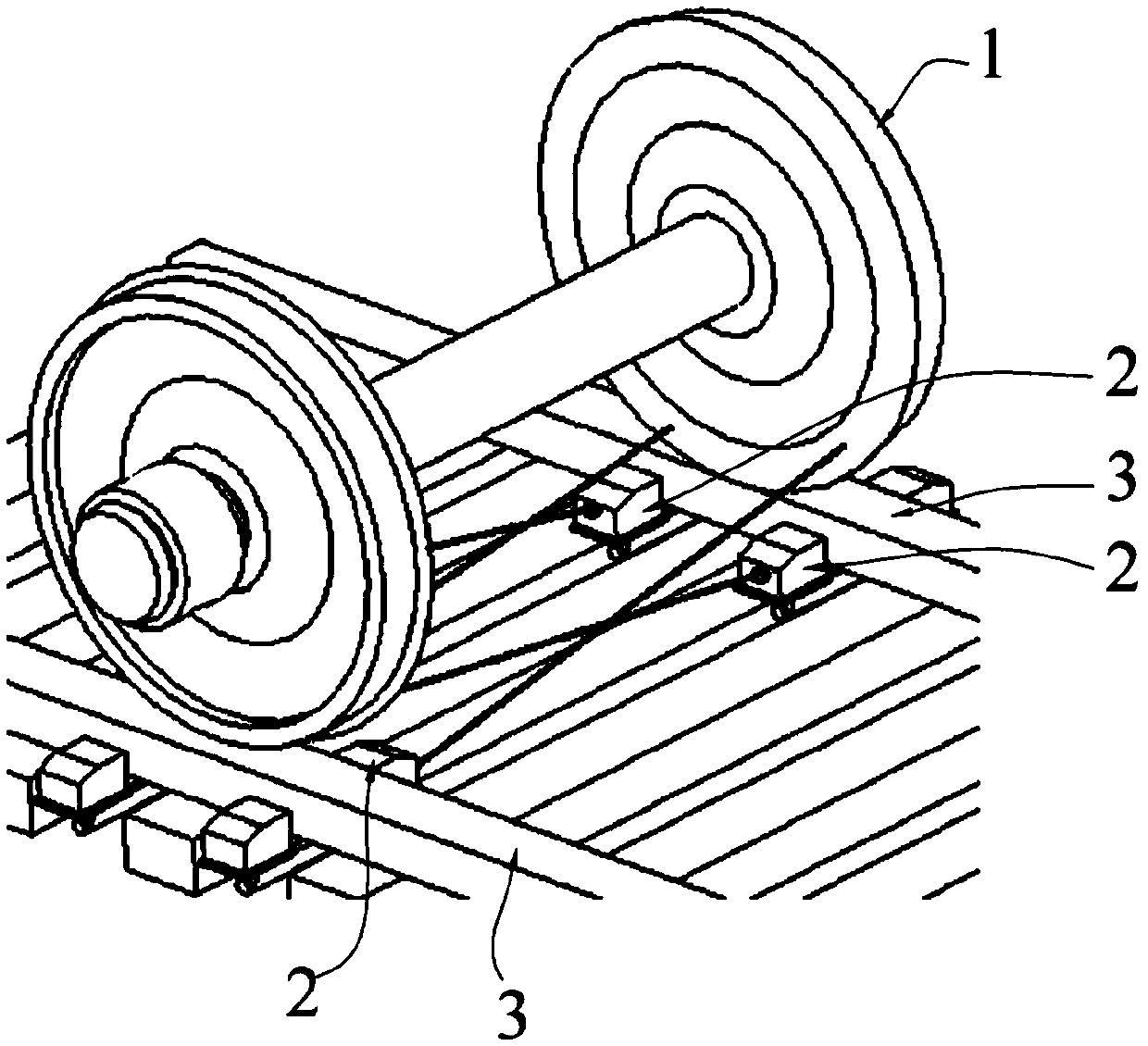

[0048] The present invention is based on the method of using the turning bed measurement data of the train wheel on-line monitoring system, which is suitable for the non-falling wheel turning bed commonly used in the repairing and processing of train wheels. The left side sensor and the right side sensor of the height, the non-falling wheel turning bed is based on the measured train wheel diameter to carry out the turning process of the train wheel.

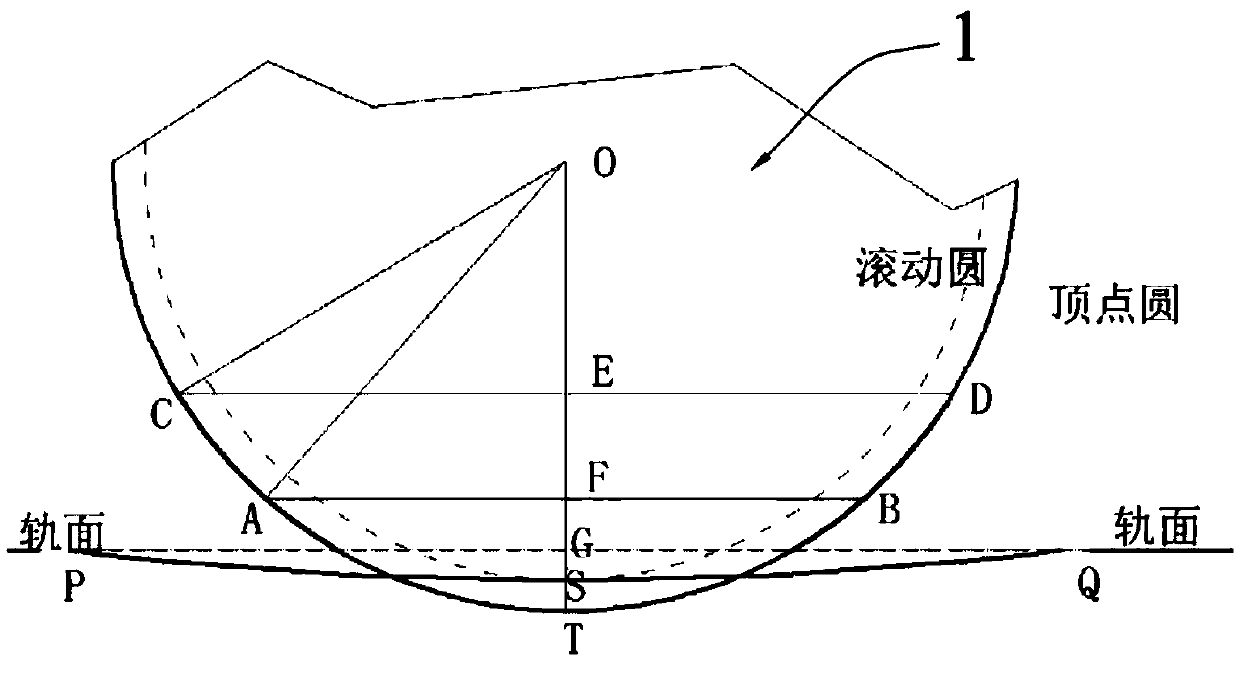

[0049] The present invention is based on the method for using the turning bed measurement data of the on-line monitoring system of the train wheel, and the on-line monitoring system of the train wheel can be any one in the prior art that can measure the chord length of the low point of the train wheel when the train is in the running state and high point chord length system, wherein, the low point chord length and the high point chord length are respectively the chord length half length of the chord at the lower position and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com