Automatic material rolling machine

A coiling machine and automatic technology, applied in the direction of coiling strip, thin material handling, transportation and packaging, can solve the problems of easy occurrence of danger and low degree of automation, and achieve the effect of eliminating danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

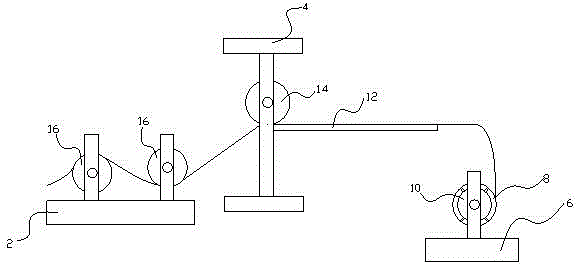

[0017] Such as figure 1 As shown, the present invention includes a tensioning device 2, a conveying device 4 and a coil device 6, wherein:

[0018] The conveying device 4 is used to drive the metal mesh to move linearly;

[0019] The tensioning device 2 is used for tensioning the metal mesh sheet before entering the conveying device 4;

[0020] The coiling device 6 is located behind the conveying device 4, and it includes a coiling drum 8 and a suction device 10, the coiling drum 8 is used for rotation after being in contact with the metal mesh, and the suction The feeding device 10 is used for adsorbing the metal mesh sheet on the winding roller 8 after it contacts with the winding roller 8 .

[0021] As a further improvement of the present invention, the conveying device 4 includes a feeding plate 12 arranged horizontally and used to place the metal mesh sheet, and a feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com