Orifice width adjustable floating body inspection steel gate

An adjustable gate technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of fixed width of pontoon-type maintenance stacking beam gates, and can not be used for gate slots with various orifice widths, so as to reduce engineering costs. Effects of construction investment, gate weight reduction and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

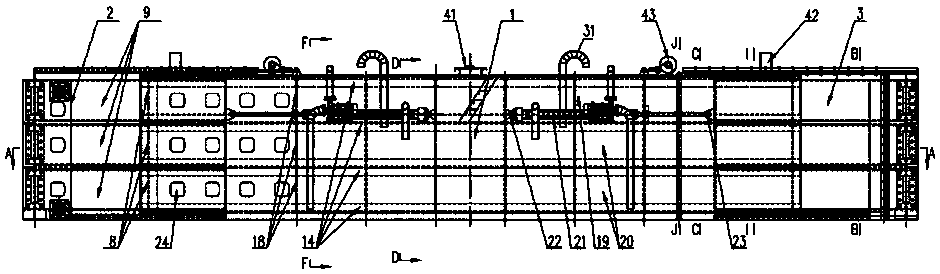

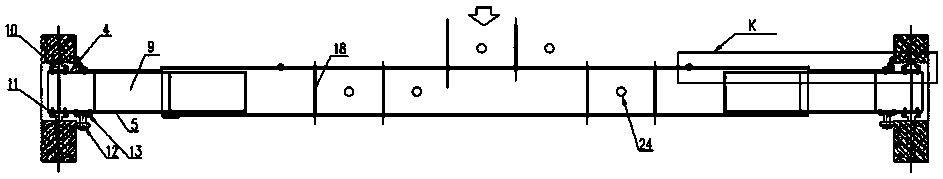

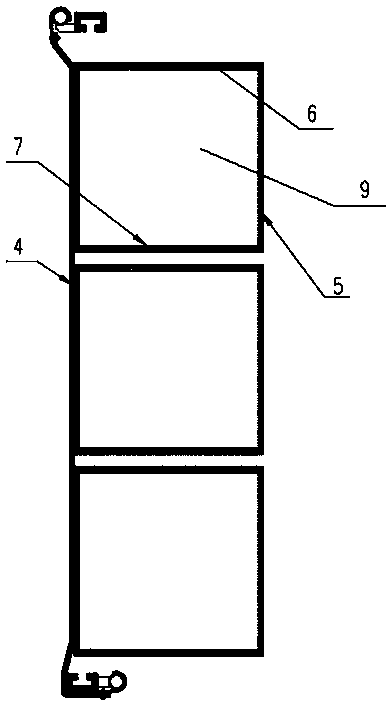

[0029] The present invention will be described in more detail below through specific embodiments in conjunction with the drawings.

[0030] Such as figure 1 , 2 As shown in 3, the gate leaf of the floating-body inspection steel gate with adjustable orifice width of the present invention is composed of the middle section gate leaf 1 and the left section gate with the same structure and symmetrically overlapped on the left and right ends of the middle section gate leaf 1. The door leaf 2 and the right section of the gate leaf 3 are composed of the sealed box-shaped overlap unit of the right (or left) gate leaf 3 by stacking three layers of sealed box beams spaced up and down. The sealed box beam consists of A three-layer sealed cavity 9 formed by welding the upstream flange plate 4, the downstream flange plate 5, the top web 6 and the bottom web 7, the end and the middle rectangular baffle 8 to produce buoyancy. ; The other end of the gate leaf of the right section (or left section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com