Automatic kelp harvesting platform with structure of reducing floating ball clamping possibility

A clamping structure and platform technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems that affect the efficiency of kelp picking, increase the workload of workers, and affect work efficiency, etc., to achieve easy operation, reduce labor, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and example the present invention will be further described:

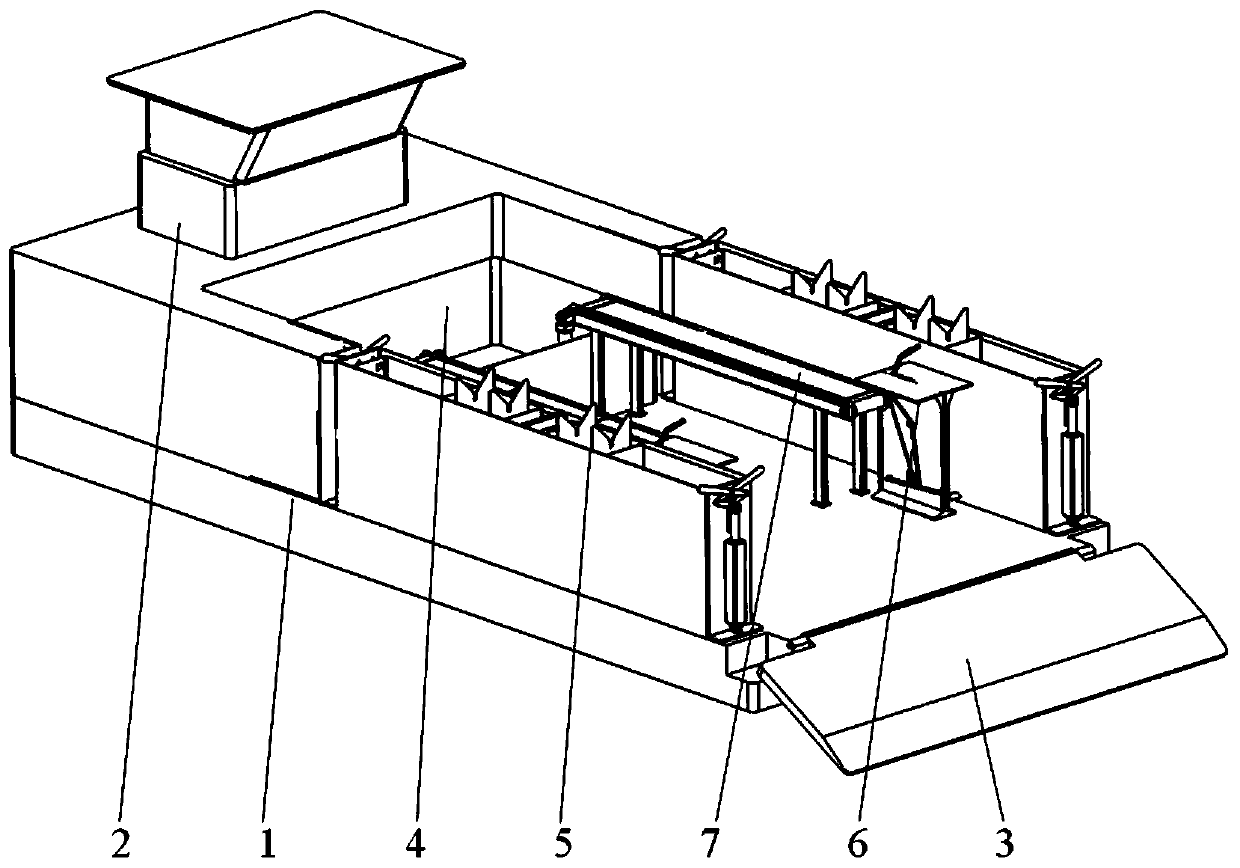

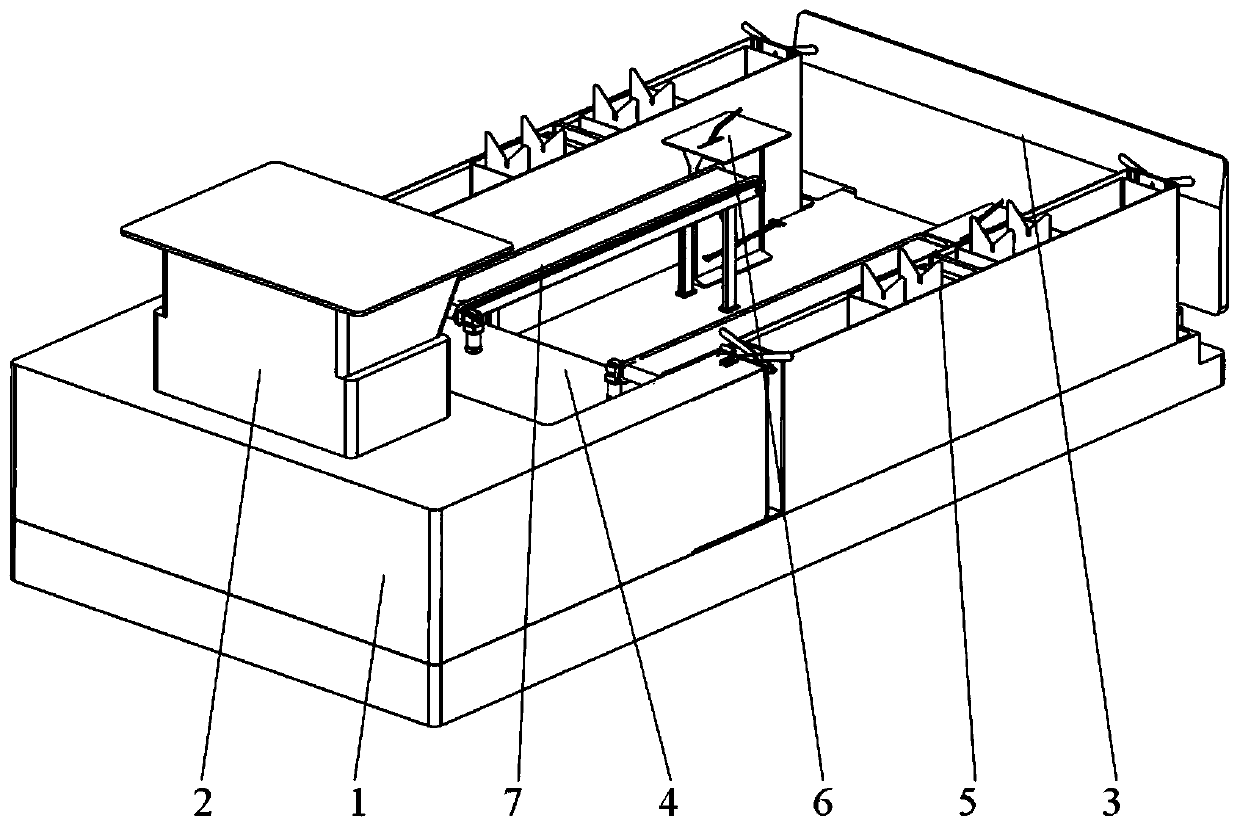

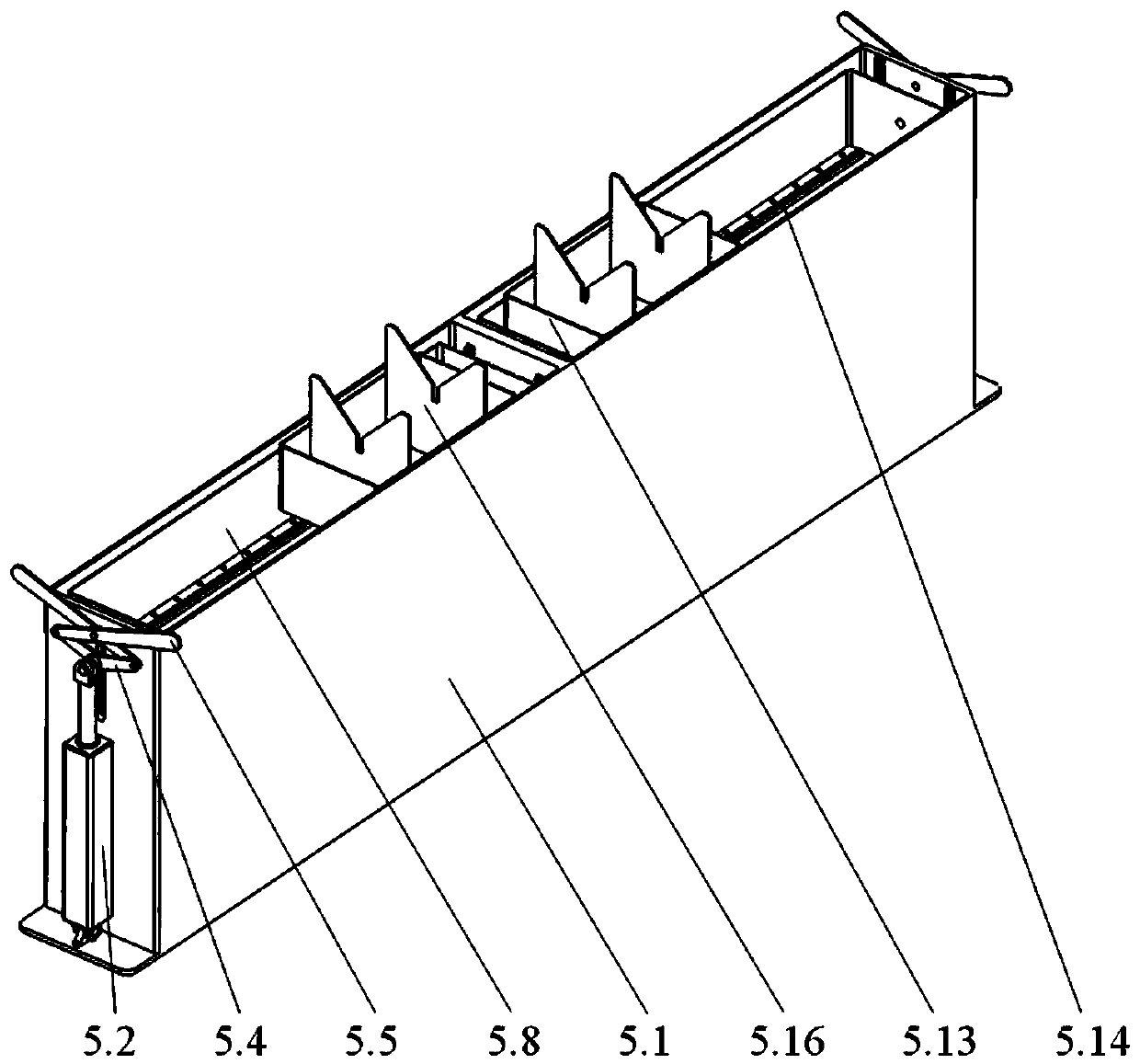

[0020] Such as Figure 1-Figure 8As shown, the present invention has an automatic kelp harvesting platform with a clamped structure for reducing floating balls, including a harvesting platform chassis 1, an operation control cabin 2, a front baffle 3, a storage box 4, a regular extraction assembly 5, a cutting assembly 6 and The conveying assembly 7, wherein the rear part of the harvesting platform chassis 1 is a U-shaped platform, the front part of the harvesting platform chassis 1 is an operation deck, and a hinged seat is opened in the middle of the front end of the harvesting platform chassis 1, and the operation control cabin 2 is fixed on the harvesting platform The middle part of the U-shaped platform of the chassis 1 is connected to the centering cylinder I 5.2, the centering cylinder II 5.3, the lifting cylinder I 5.6, the lifting cylinder II 5.7 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com