Top ring beam structure for SMW piles and construction method thereof

A construction method and top ring beam technology, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of poor site environment, waste of profiled steel, waste of space, etc., and achieve the effect of saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

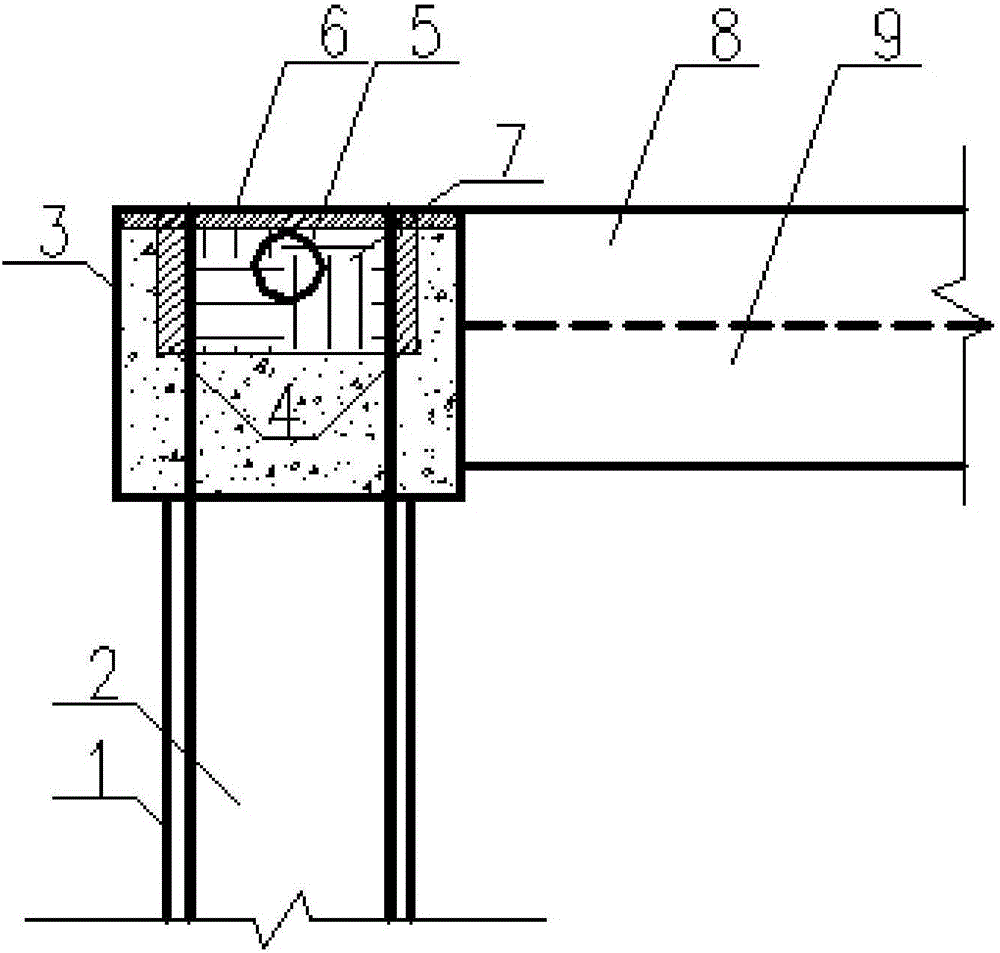

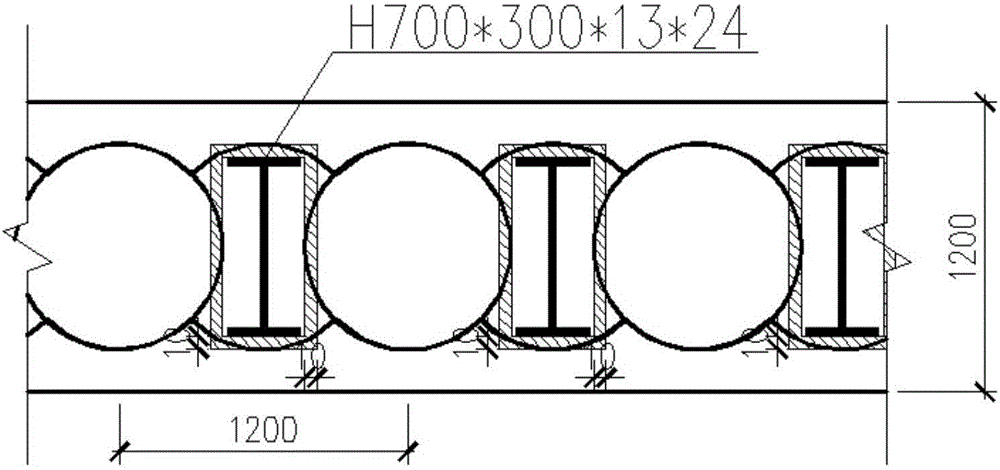

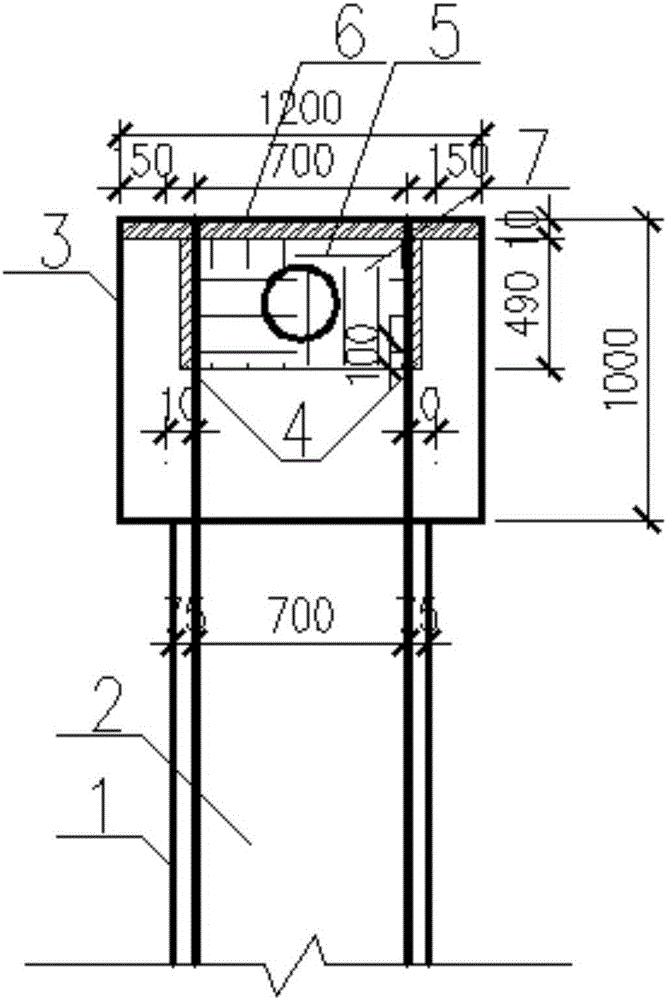

[0035] This embodiment takes foundation pit construction as an example. The depth of the foundation pit is 10m to 15m. The foundation pit enclosure structure uses SMW piles. In this embodiment, the diameter of the cement-soil mixing pile 1 of the SMW piles is 850mm@600mm Arrangement, overlap 250mm; steel 2 is H700*300*13*24, arranged every other, with a spacing of 1200mm. Combine below figure 1 and Figure 4 The composition and structure of the pile top ring beam structure of the SMW construction method in this embodiment are described. The pile top ring beam structure of the SMW construction method includes setting top ring beams 3 on several cement-soil mixing piles 1, part or all of the cement-soil mixing piles 1 are inserted with section steel 2, and the top ring beams 3 are reinforced concrete strips structure, the upper surface of the shaped steel 2 protrudes a certain distance from the upper surface of the cement-soil mixing pile 1, the upper surface of the top ring b...

Embodiment 2

[0041] read on Figure 1 to Figure 4 , the present invention also provides a construction method of the SMW construction method pile top ring beam structure as described in Embodiment 1, comprising the following steps:

[0042] In the first step, the construction of the cement-soil mixing pile 1 is completed, and the section steel 2 is inserted in place as required.

[0043] The second step is to excavate the 3 grooves of the top ring beam and bind the steel bars.

[0044] The third step is to set the bottom mold and side mold of the top ring beam 3.

[0045] The fourth step is to fix the wooden mold 4 at the place where the hole 7 needs to be reserved.

[0046] The fifth step is continuous pouring of concrete. Since the ground connection wall can be poured continuously, the construction is convenient and quick.

[0047] The sixth step, top ring beam 3 maintenance.

[0048] In the seventh step, plain soil is filled in the hole 7 . During use, plain soil is filled in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com