Construction method of No.0 block of continuous rigid frame bridge of double-thin-wall pier

A construction method and technology of thin-walled piers, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as large impact on pier body structure and difficult construction, and achieve convenient construction, simple and convenient handling, and easy disassembly and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

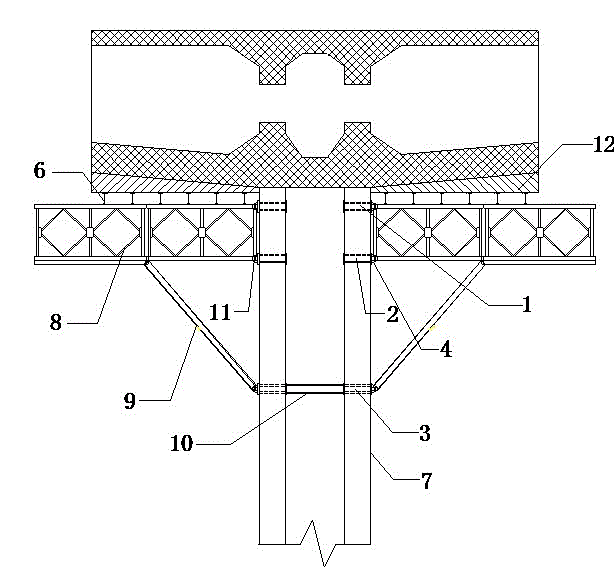

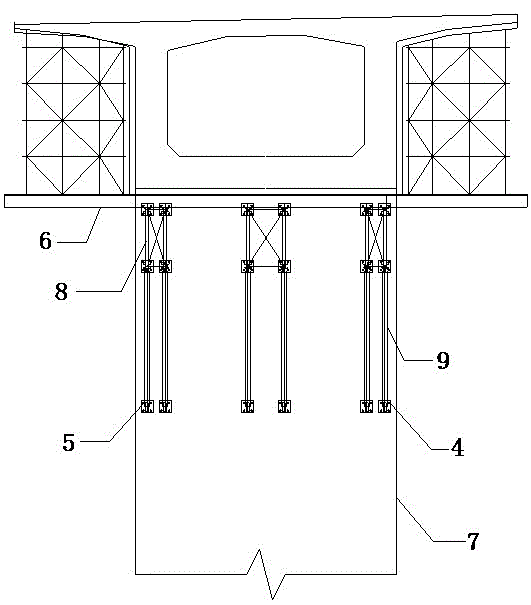

[0032] Example 1: Continuous rigid frame bridge with double thin-walled piers. The main bridge is a continuous rigid frame bridge of 40m+48m+2×70m+2×48m. A rectangular cap is adopted, with a length of 8.9m, a width of 5.7m, and a thickness of 2.5m. Figure 4 As shown, the construction method of block 0 is carried out in the following steps:

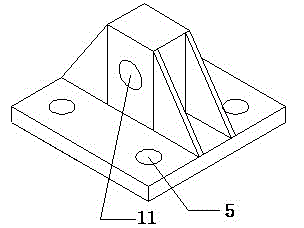

[0033] ① Installation of pier body connectors: Three rows of reserved holes are reserved in the pier body, and PVC pipes with an inner diameter of 40mm are embedded in each row of reserved holes, and φ32mm fine-rolled rebar is used to pass through the bolt holes 5 on the connector 4 to connect The piece 4 is fixed in the reserved hole on the outside of the pier body 7, wherein the vertical distance from the center of the pin connection hole 11 of the first row of reserved holes 1 to the top of the pier is 45 cm, and the second row of reserved holes 2 and the connecting piece 4 The vertical distance between the center of the pin connectio...

Embodiment 2

[0040] Embodiment 2: The difference from Embodiment 1 is that the reserved specific design position of the reserved holes in the pier body in step ① is the vertical distance from the center of the pin joint hole 11 of the first row of reserved holes 1 connector 4 to the top of the pier The vertical distance between the center of the pin connection hole 11 of the second row of reserved holes 2 connectors 4 and the center of the first row of reserved holes 1 connector pin connection holes 11 is 160 cm, and the third row of reserved holes 3 connectors 4 The vertical distance between the center pin hole 11 and the center of the pin hole 11 of the connector 4 of the second row of reserved holes 2 is 400 cm.

[0041] After the construction of the present invention is completed, the construction progress is greatly accelerated, the construction period is shortened by 35 days, and the safety and reliability of the construction are ensured. At the same time, the durability requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com