An electric heating plug vibrating powder table

A glow plug and grinding technology, applied in loading/unloading, engine components, machines/engines, etc., can solve the problems of low work efficiency and high technical requirements, and achieve the effect of perfect filling, low technical requirements and consistent filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

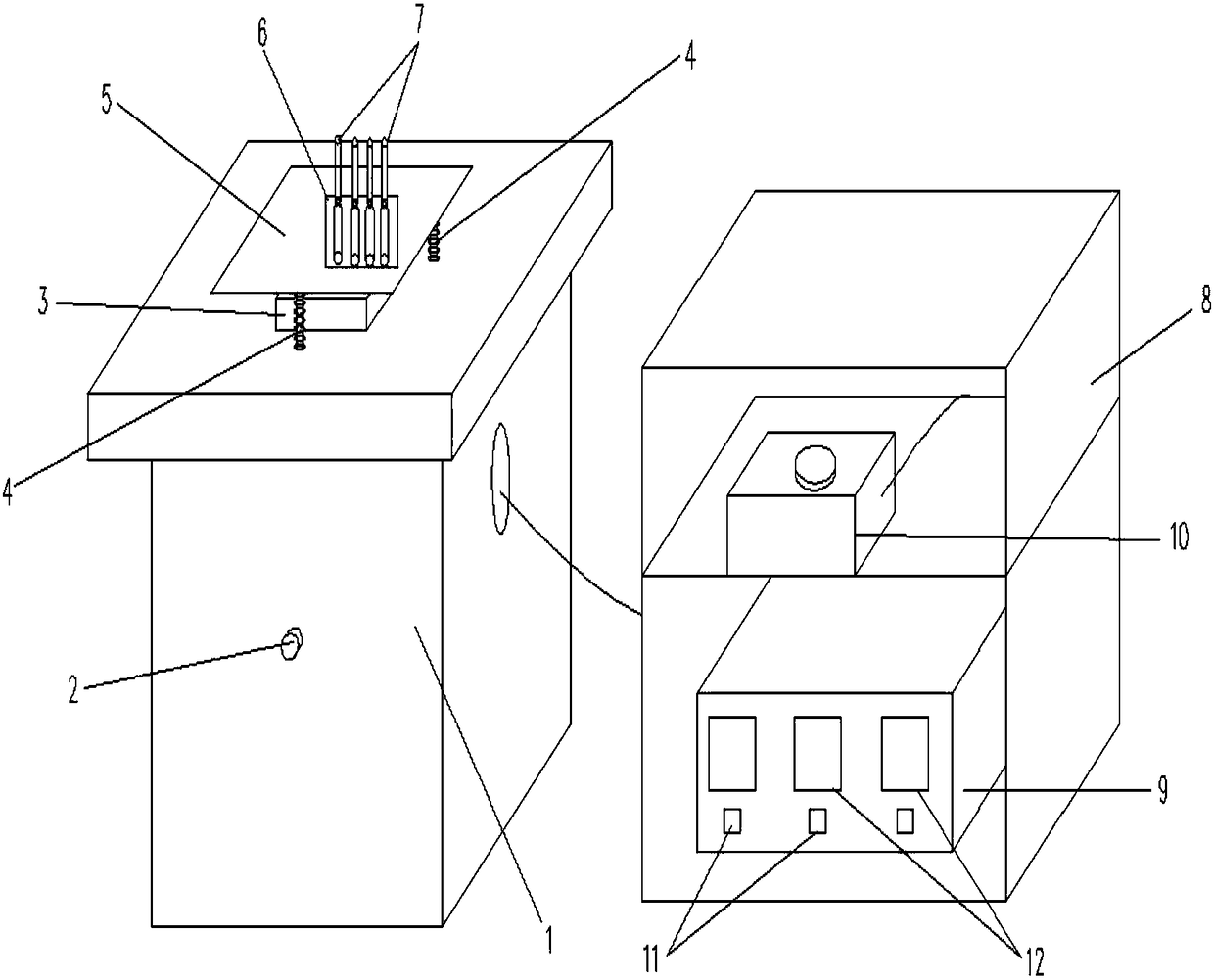

[0013] With reference to the attached drawings, in order to achieve the required technical effect of the present invention, the present invention adopts the following technical solutions: a glow plug vibrating powder table, including a powder vibrating table and a control cabinet, the powder vibrating table is provided with a switch, the vibrating powder table The powder table is provided with a transformer, the vibrating powder table is provided with a powder vibrating spring, the spring is provided with a fixed plate, and the fixed plate is provided with a vibrating powder mill, and the control cabinet includes a control box and a frequency converter. The control box is connected with the vibrating powder table, and the frequency converter is connected with the control box.

[0014] Preferably, there are four springs, and the springs are arranged in a rhombus shape and fixed on the vibrating powder table.

[0015] Preferably, the transformer is fixed in the middle of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com