Shaft structure

A technology of rotating shaft structure and anti-rotating structure, which is applied in the direction of pivot connection, etc., can solve the problems of loose bolts, high processing cost, complex structure of rotating shaft or pivot, etc., and achieve the effect of reducing combination cost and quickly linking two objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to fully understand the purpose, features and effects of the present invention, the following specific embodiments are now used in conjunction with the accompanying drawings to further describe the present invention in detail, as follows:

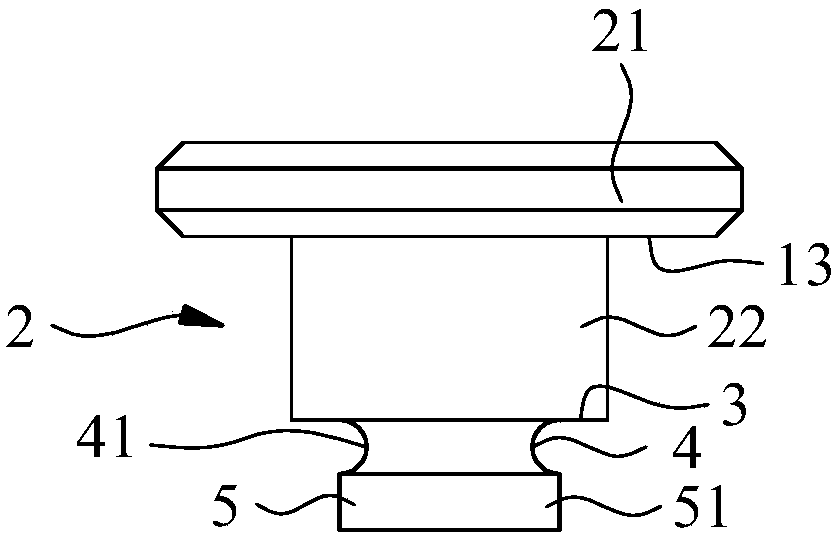

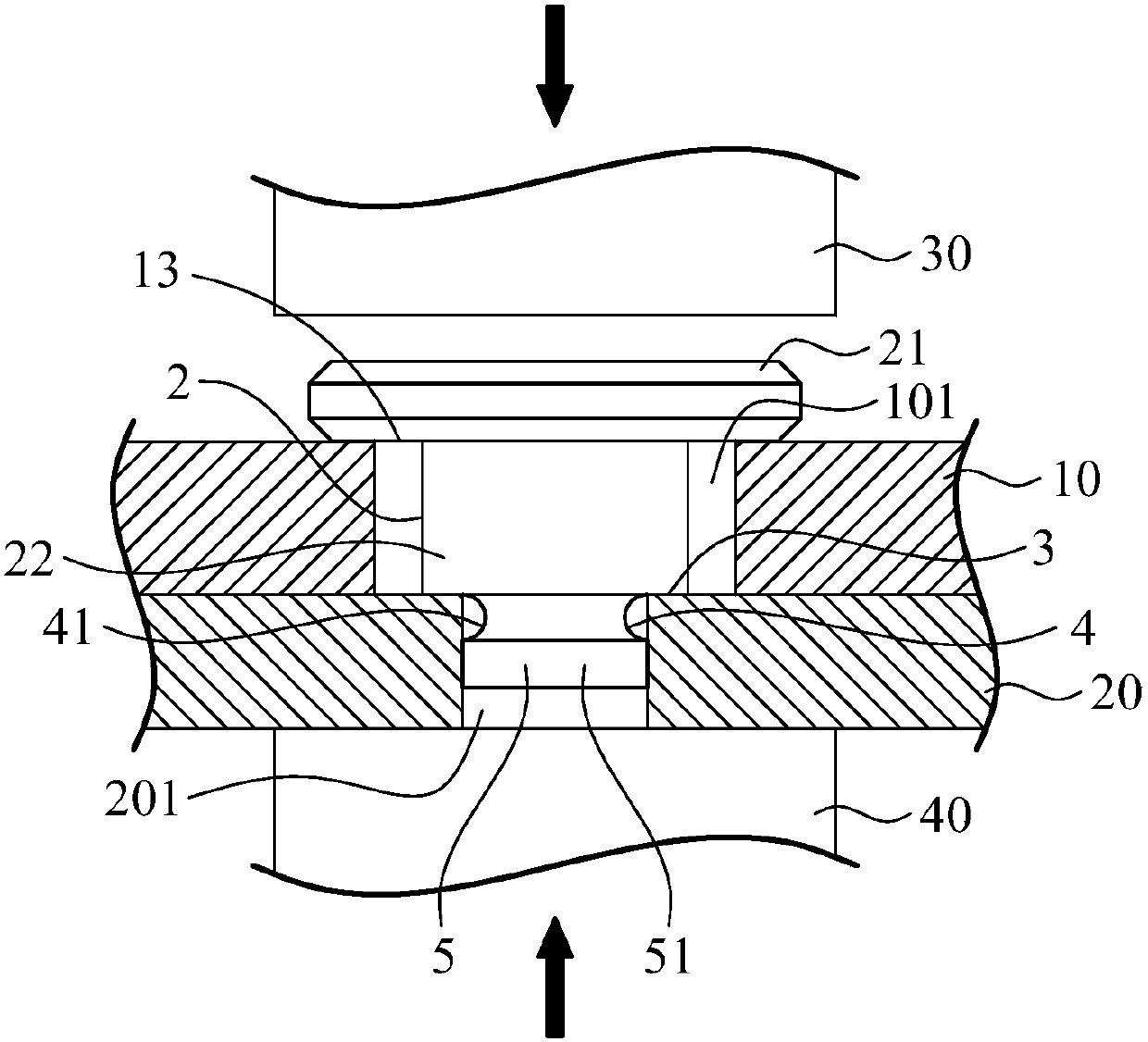

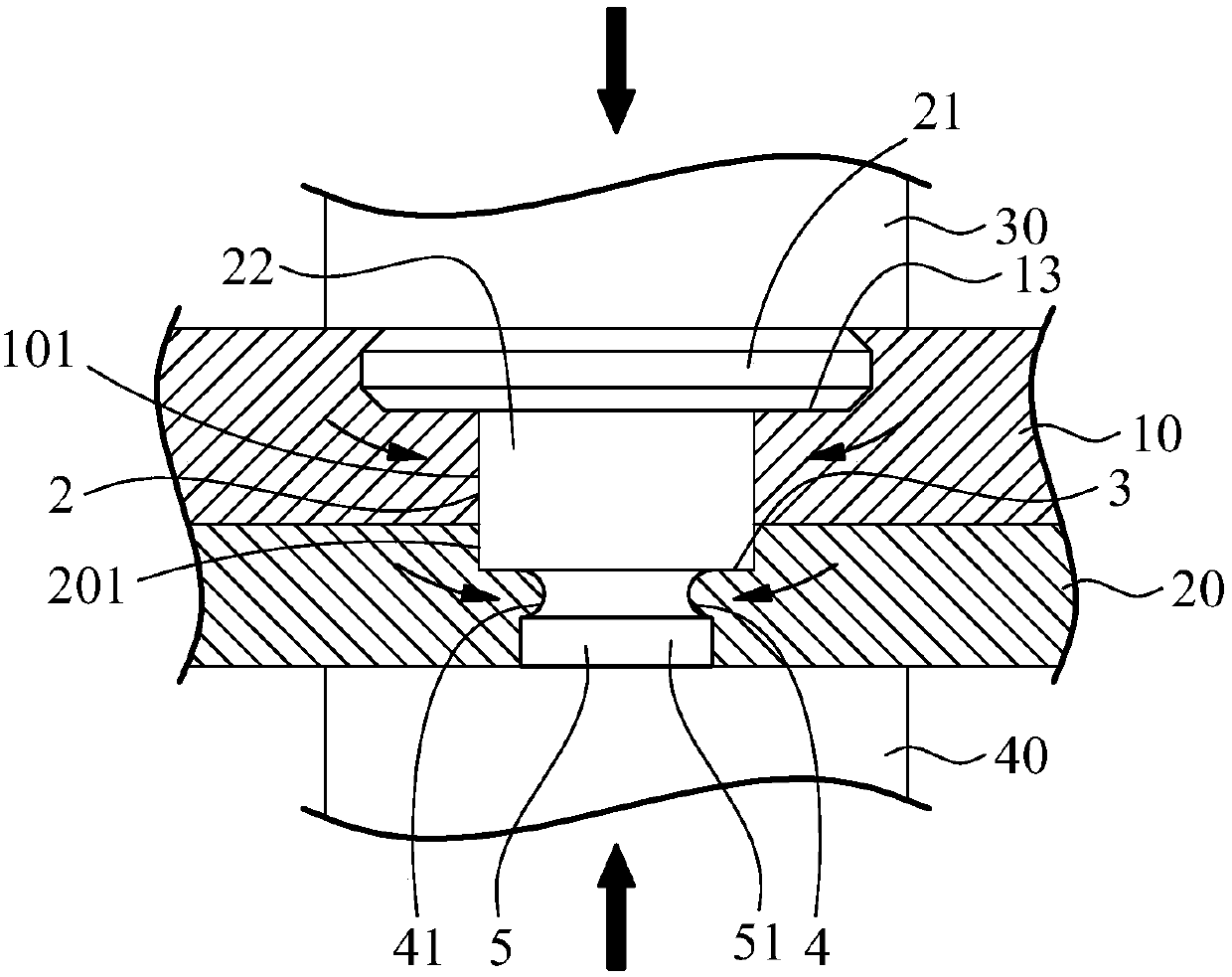

[0073] See figure 1 As shown, it is shown as a shaft structure of the present invention, which is used to quickly link the first object 10 and the second object 20 (such as figure 2 and image 3 Shown), and enable the first object 10 and the second object 20 to rotate relative to each other (such as Figure 4 Shown). Another example figure 1 As shown, the first preferred embodiment of the rotating shaft structure is composed of a shaft body, which includes a T-shaped pressing portion 2 for squeezing or limiting and stopping the first object 10; The second pressing portion 3 of the object 20, the second pressing portion 3 is located at the bottom of the T-shaped pressing portion 2; adjacent to the second pressing portion 3 and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com