Deep groove ball bearing with stop ring

A deep groove ball bearing and snap ring technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems affecting the use of bearings, bearing failure, deviation of the outer ring of the bearing, etc., to increase the lubrication capacity, Improves service life and reduces friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

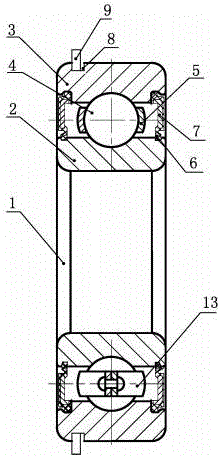

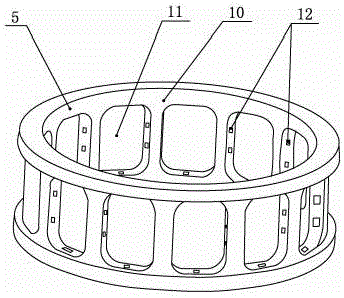

[0018] refer to Figure 1 to Figure 2 , a deep groove ball bearing with a snap ring, including a bearing body 1, the bearing body 1 includes an inner ring 2, an outer ring 3, steel balls 4, a cage 5, a sealing ring 6 and a skeleton 7, the outer ring The outer wall of 3 is inwardly recessed to form a stop groove 8, and a stop ring 9 is arranged in the stop groove 8. The stop ring 9 is an open elastic part. The depth of the stop groove 8 is the same as that of the outer ring 3. The thickness ratio is 0.2-0.3, the cage 5 is placed between the inner ring 2 and the outer ring 3, the cage 5 includes a frame body 10, and a plurality of retaining holes 11 penetrating through the thickness direction of the frame body 10, A plurality of grooves 12 are uniformly arranged in the holding hole 11, and the grooves 12 are filled with lubricating grease.

[0019] By adopting the above te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com