Defect region detection method and device

A region and defect technology, which is applied in the field of defect region detection methods and devices, can solve the problem of low efficiency in determining the target difference threshold, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

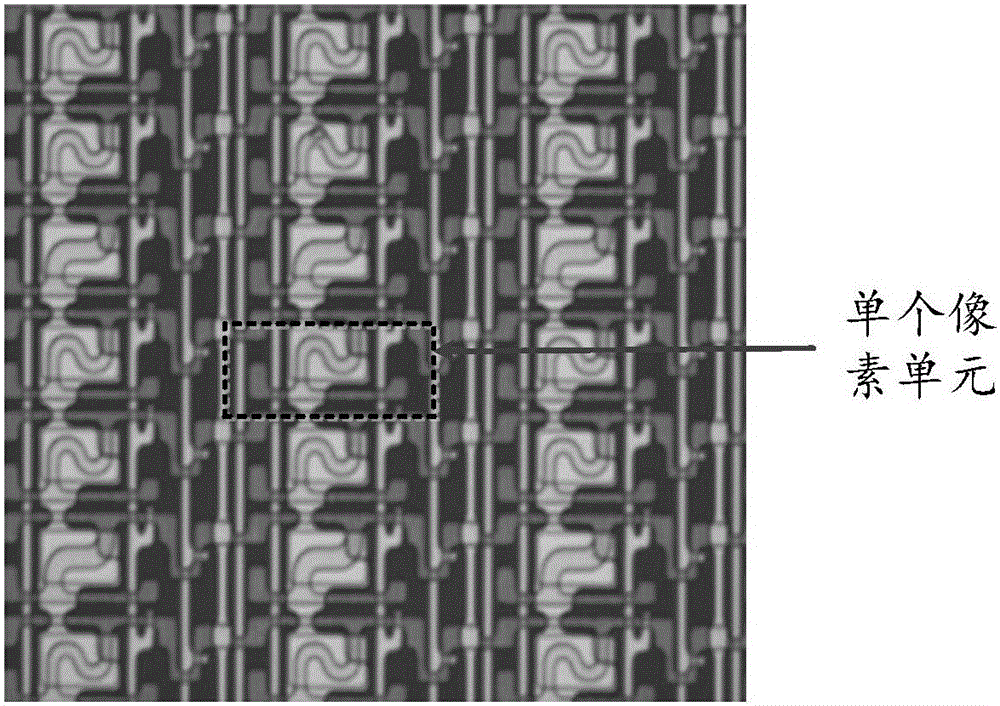

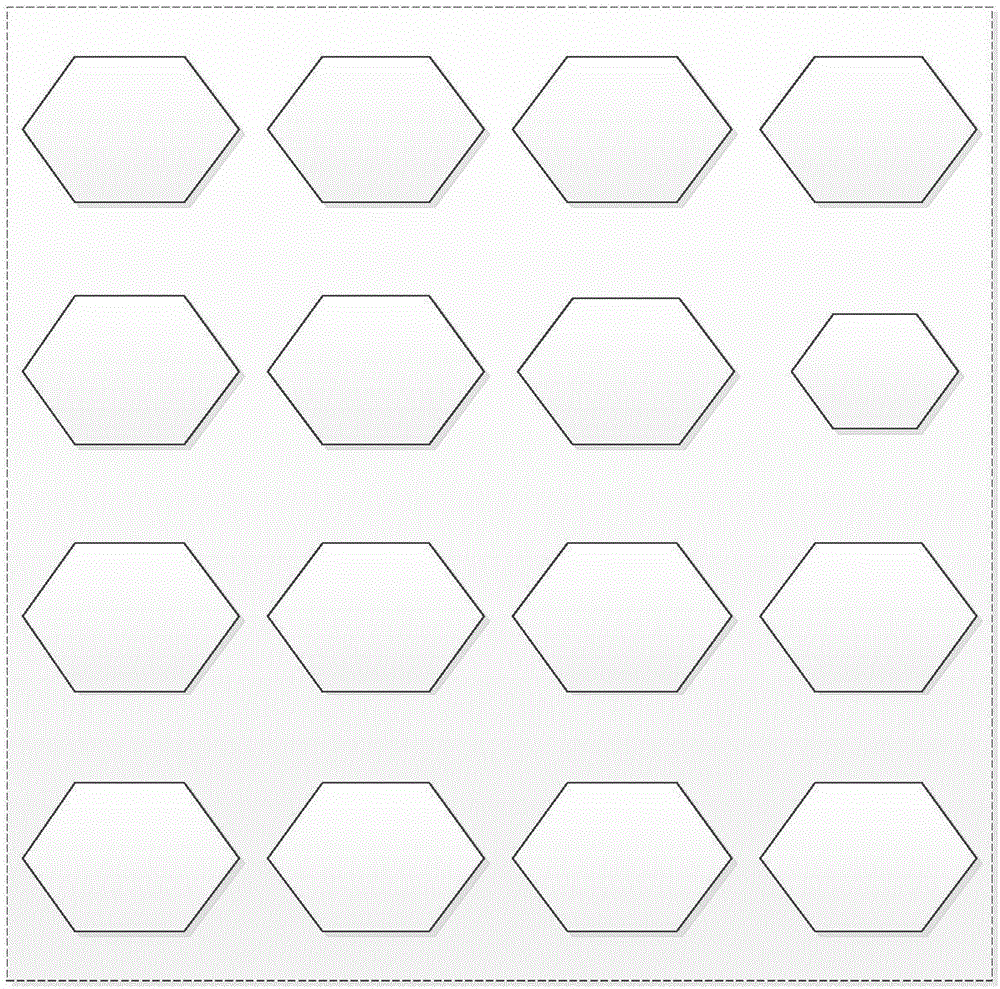

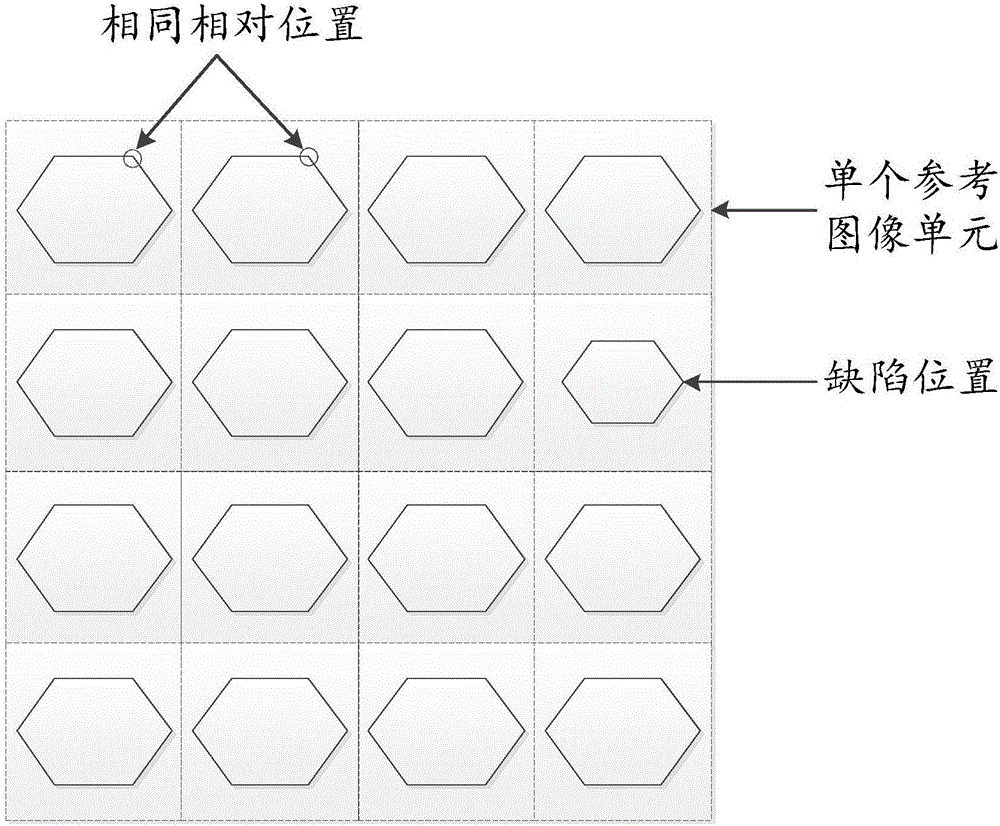

[0055] In order to solve the problem in the prior art that determining the target difference threshold by manual attempts leads to low determination efficiency of the target difference threshold, Embodiment 1 of the present application provides a defect area detection method. The execution subject of the method for detecting a defect region provided in the embodiment of the present application may be a defect detection system, for example, a defect detection system for detecting a defect region in a panel, and the like.

[0056] For the convenience of description, the implementation of the method will be introduced below by taking the defect detection system for detecting the defect area in the panel as an example where the subject of execution of the method is. It can be understood that the execution subject of the method is a defect detection system for detecting defect areas in the panel is only an exemplary description, and should not be understood as a limitation of the me...

Embodiment 2

[0090] In order to solve the problem in the prior art that determining the target difference threshold by manual attempts leads to low determination efficiency of the target difference threshold, Embodiment 2 of the present application provides a defect area detection device. The structural schematic diagram of the defect area detection device is as follows: Figure 4 As shown, it mainly includes the following functional units:

[0091] The coordinate parameter receiving unit 21 is configured to receive the coordinate parameters of each first pixel point in the grayscale image input by the user, and the first pixel point is a pixel point on the grayscale image corresponding to the actual defect area in the detected area;

[0092] A grayscale value determination unit 22, configured to determine the grayscale value of each first pixel point and the grayscale value of each second pixel point according to the coordinate parameters of each first pixel point in the grayscale image i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com