Environment test device refrigerating system and energy-saving working condition fast determination method thereof

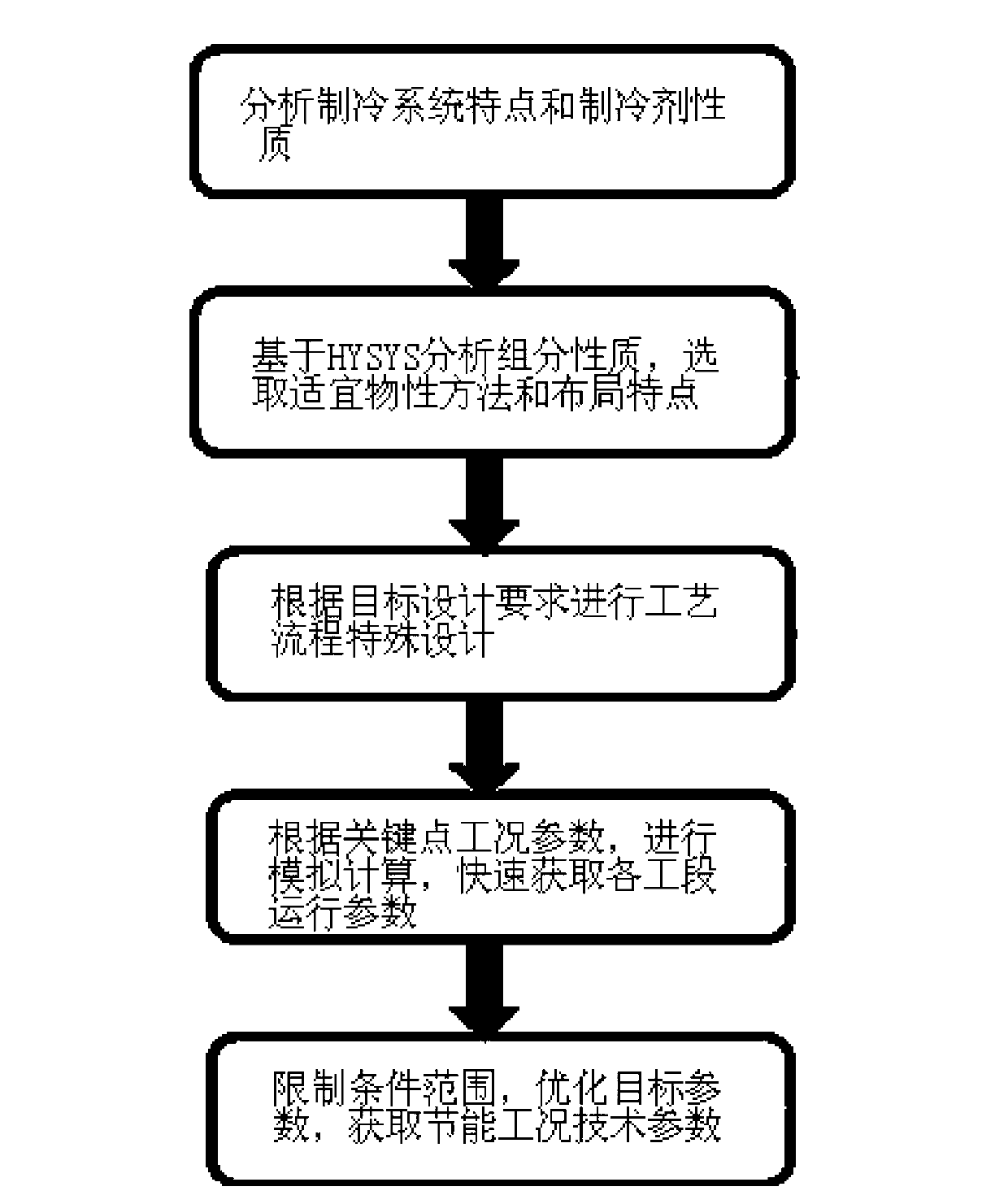

The technology of an environmental test device and a refrigeration system is applied in the field of rapid determination of the energy-saving working conditions of the refrigeration system of the environmental test device, which can solve the problems of low design efficiency, long time consumption, limitation of extreme conditions, etc., and achieve the effect of fast and efficient determination and improvement of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

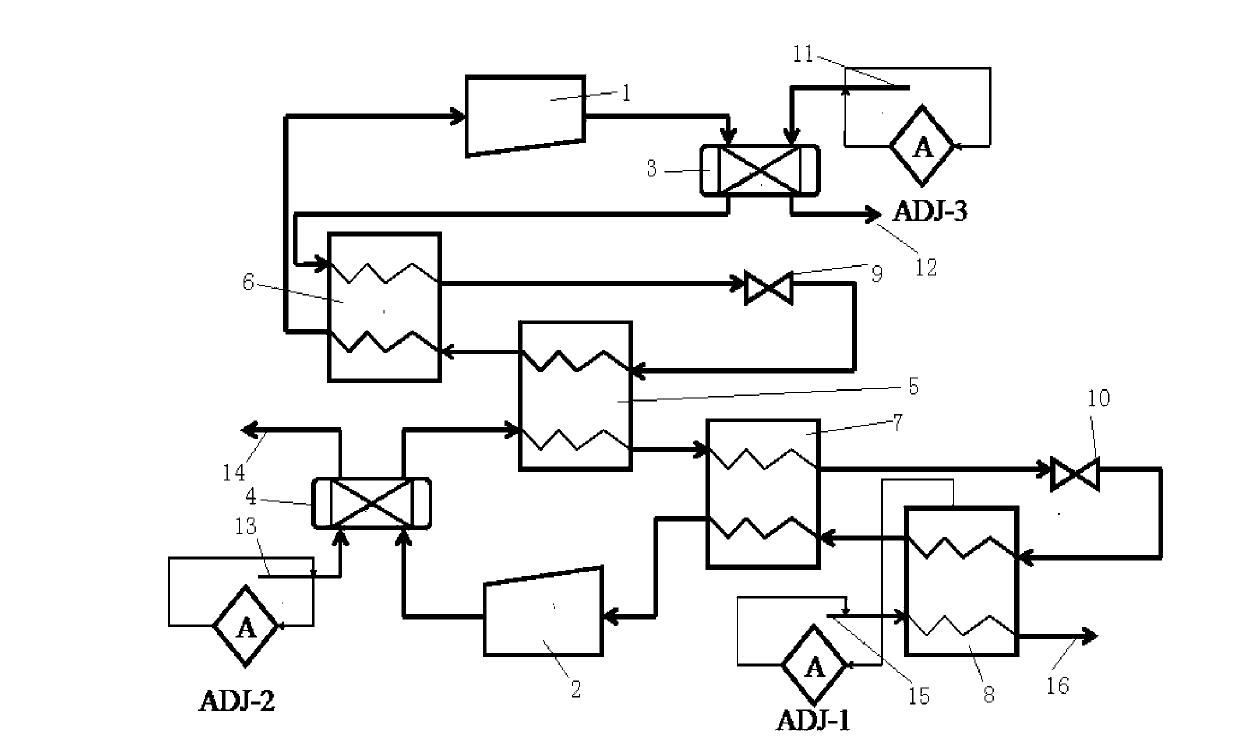

[0043] Such as figure 2 As shown, a refrigeration system of an environmental test device includes a high-temperature stage and a low-temperature stage, and the high-temperature stage includes a compressor-1, and the exhaust pipe of the compressor-1 is connected to the inlet of a condenser 3, The outlet of the condenser 3 is connected to the inlet of the first pipeline of the regenerator 6, the outlet of the first pipeline is connected to the inlet of the expansion valve 9, and the outlet of the expansion valve 9 is connected to the inlet of the first pipeline of the condensing evaporator 5, and the outlet of the first pipeline is connected to the inlet of the first pipeline of the condensing evaporator 5. The outlet of a pipeline is connected to the inlet of the second pipeline of the regenerator-6, the outlet of the second pipeline is connected to the suction pipe of the compressor-1, and the condenser 3 has a cooling water inlet 11 and cooling water outlet 12; the low-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com