Display panel, display panel test system and test method for display panel

A display panel and test method technology, applied to static indicators, instruments, etc., can solve the problems that it is difficult to obtain the real impedance of thin film transistors, and the volt-ampere characteristic curve cannot be truly reflected, and achieve the effect of consistent impedance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

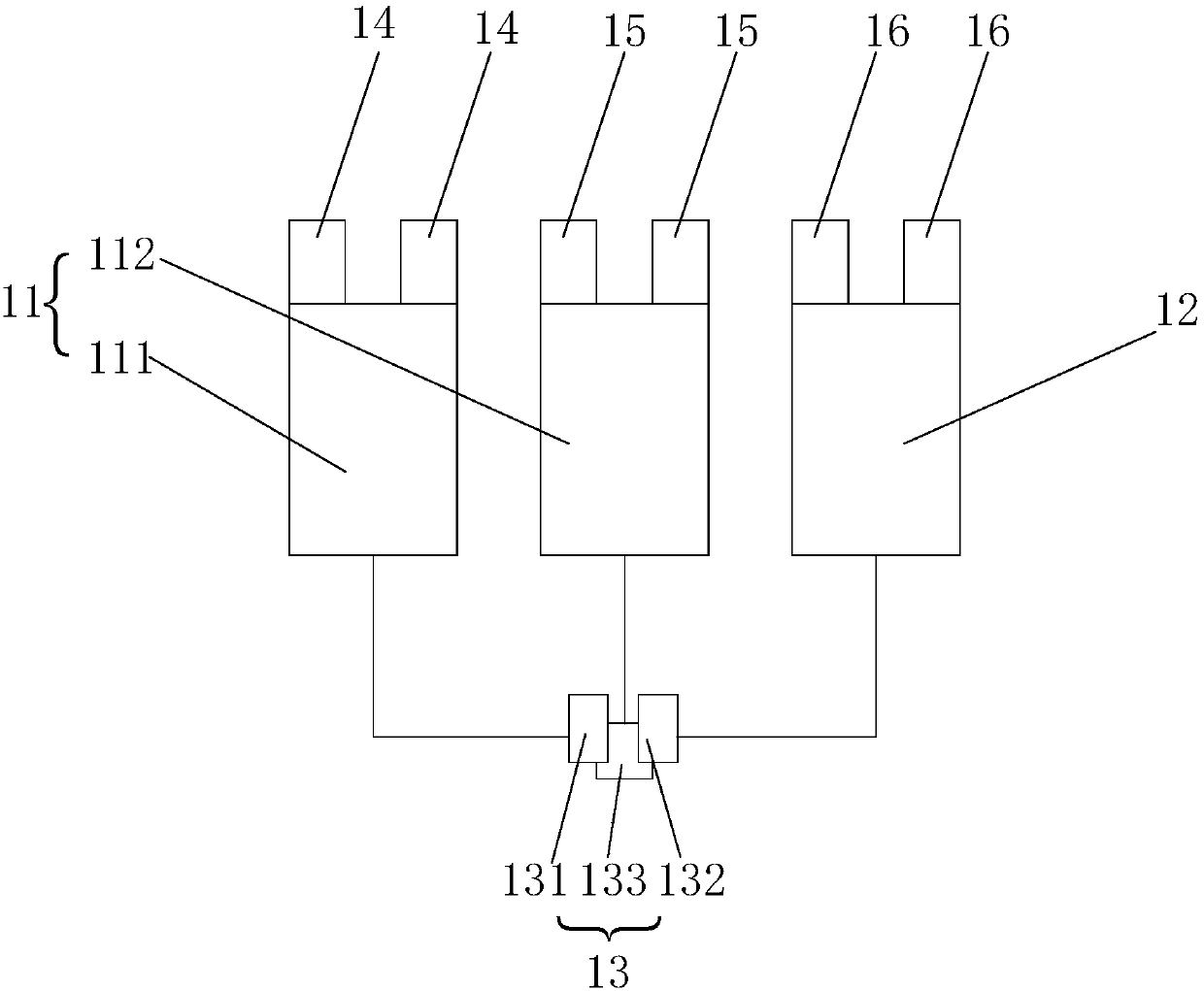

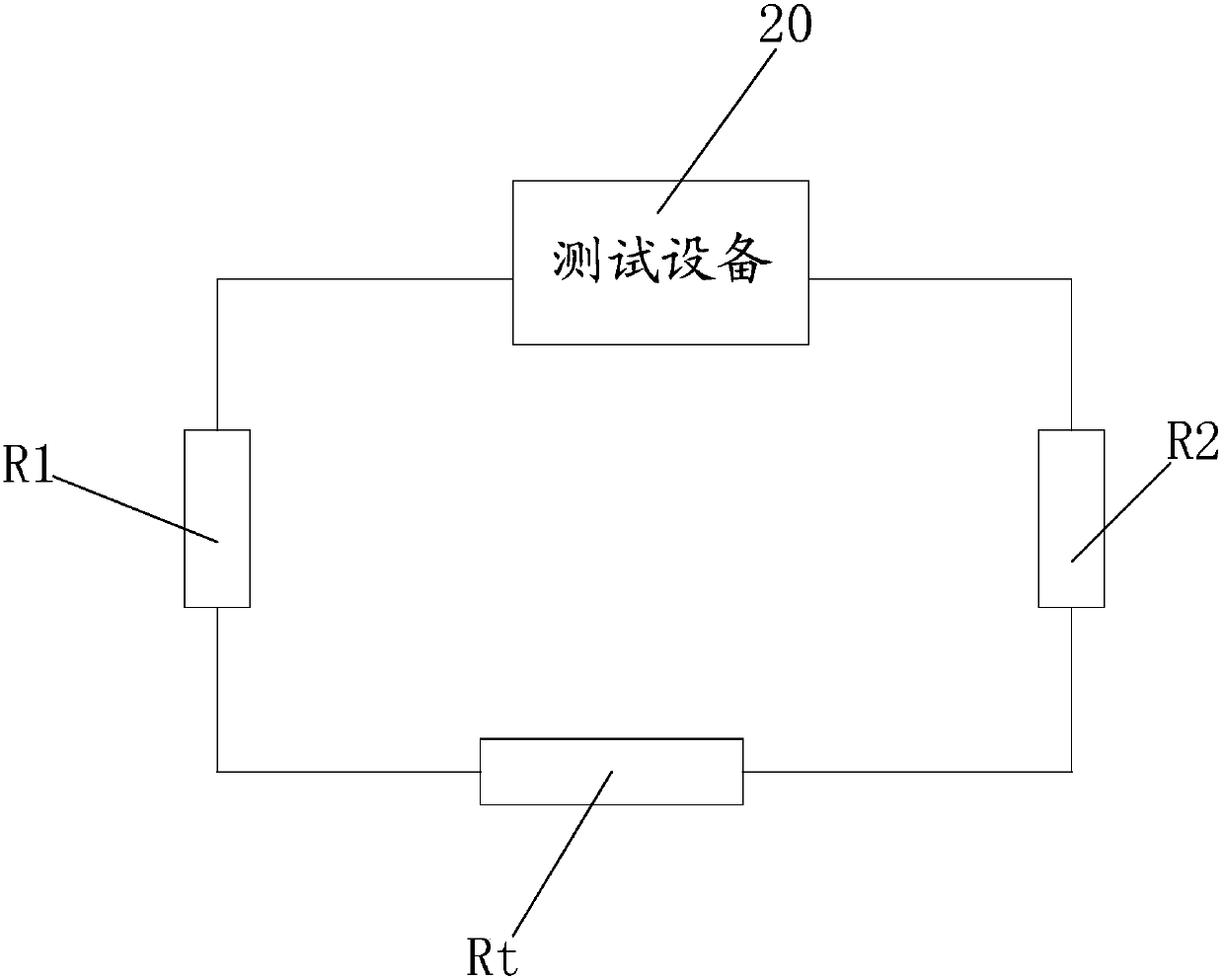

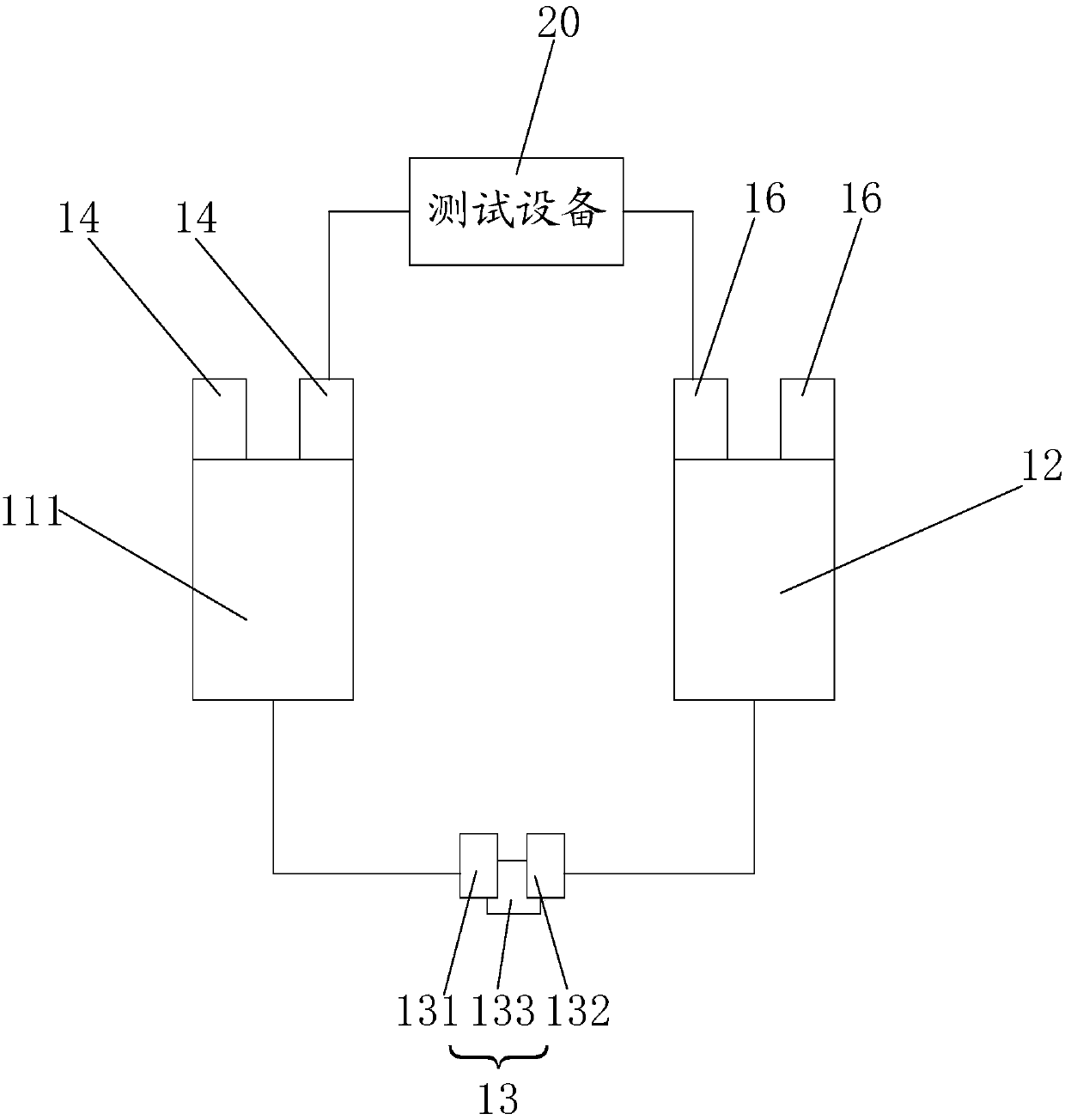

[0024] see figure 1 , figure 1 It is a schematic diagram of the structural principle of a preferred embodiment of the display panel of the present invention. In this embodiment, the display panel includes: an in-plane TFT 11 , a pixel electrode layer 12 , a TFT for testing 13 , a first metal layer test terminal 14 , a second metal layer test terminal 15 and a pixel electrode layer test terminal 16 .

[0025] Both the in-plane thin film transistor 11 and the pixel electrode layer 12 are located inside the display panel, and the in-plane thin film transistor 11 includes a first metal layer 111 and a second metal layer 112 . The display panel includes two opposing substrates, such as a thin film transistor array substrate and a color filter substrate. The in-plane thin film transistor 11 and the pixel electrode layer 12 are both located on the thin fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com