Integrated Solar Collectors Using Epitaxial Lift Off And Cold Weld Bonded Semiconductor Solar Cells

A technology of solar cells and collectors, applied in semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as incident photon loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

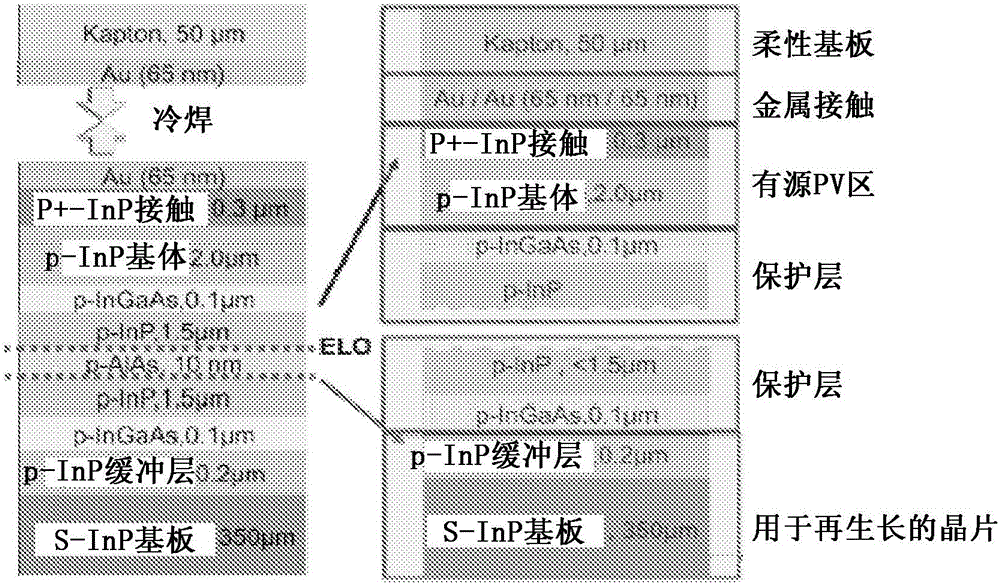

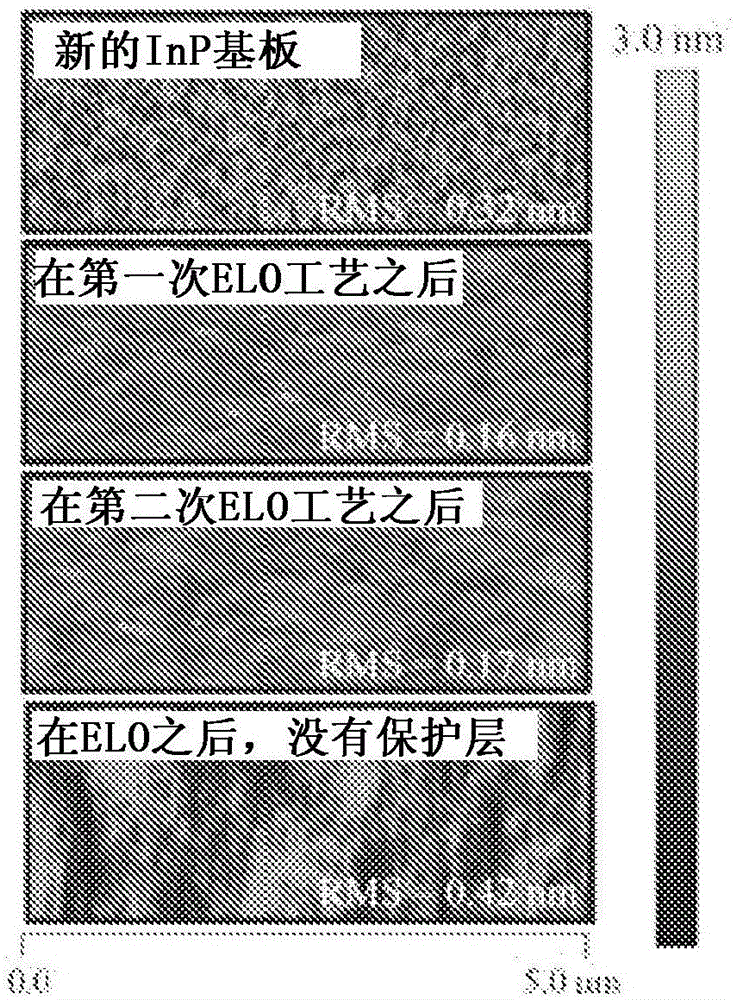

[0058] exist figure 1 One embodiment of the ELO process is schematically shown in . Epitaxial growth begins first with a chemically different thin "protective layer" consisting of InGaAs and Inp, a sacrificial layer of AlAs, a second set of protective layers of InP and InGaAs and finally the active photovoltaic cell layer. Next, the top epitaxial layer is coated with Au as a very thin plastic (e.g., Kapton TM , a polyimide film registered trademark by DuPont) main substrate. By pressing these two clean Au surfaces together with a pressure of only a few kilopascals, they electronically form a continuous, permanent, adhesive-free, cold-welded bond with properties that are indistinguishable from those of a single bulk Au film. difference.

[0059] Once bonded to the plastic handle, the wafer is ready for ELO. Cold solder bonding is only used in the ELO process (the epi layer is permanently attached to the foil substrate before peeling off the mother substrate for eventual re-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com