PV cable laying method for large-scale photovoltaic power generation projects

A photovoltaic power generation and cable laying technology, applied in the direction of cable laying equipment, etc., can solve the problems of large area of photovoltaic area, waste of PV cables, difficult organization of PV cable laying work, etc., and achieve the effect of improving laying efficiency and saving cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

[0020] The invention provides a PV cable laying method for a large-scale photovoltaic power generation project, which includes the following steps:

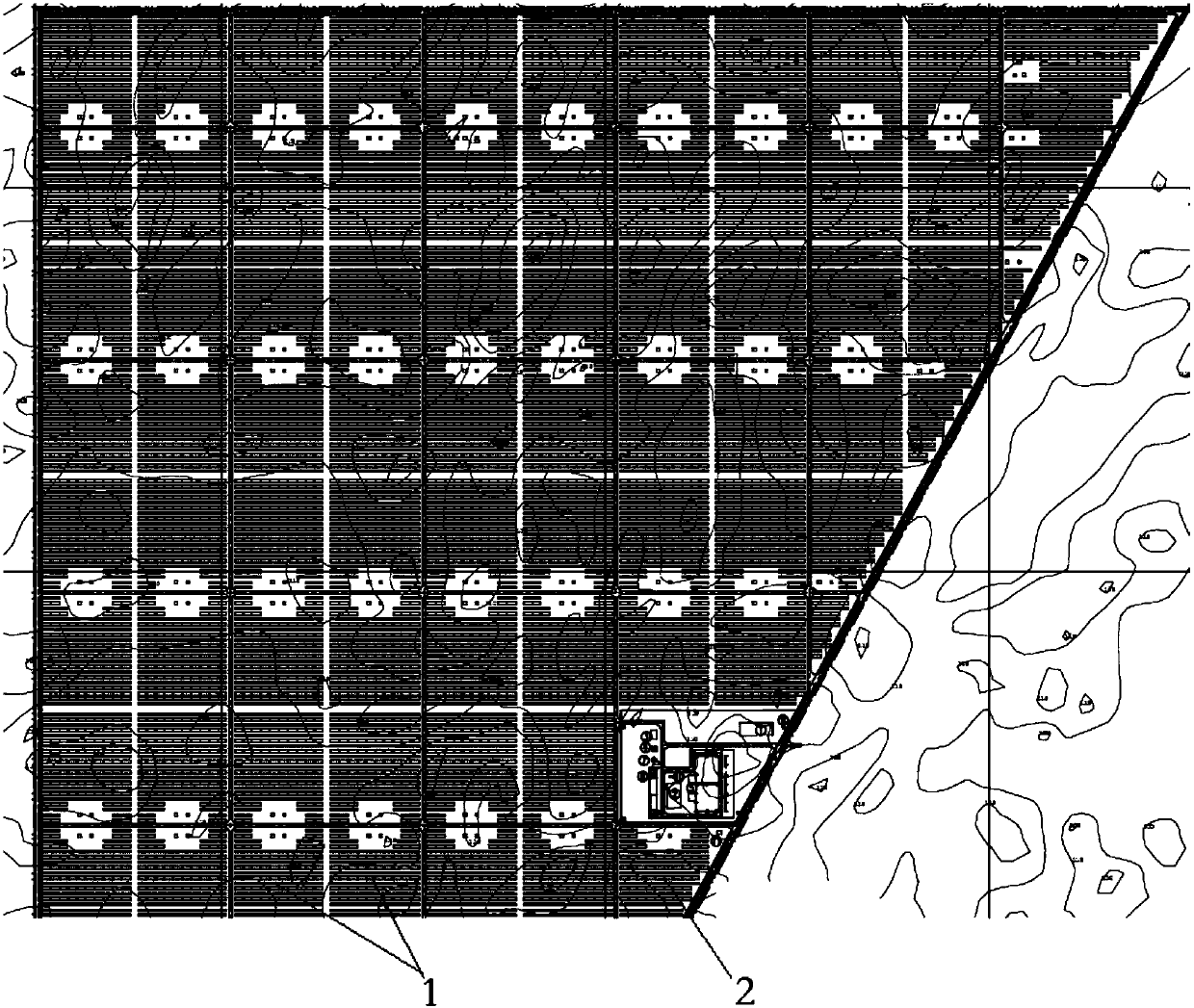

[0021] S1. Obtain the PV cable parameters of each area according to the design partition of large-scale photovoltaic areas; figure 1 As shown, the design partition of S1 large-scale photovoltaic area includes standard area 1 and special-shaped area 2, and standard area 1 is designed according to 1MW.

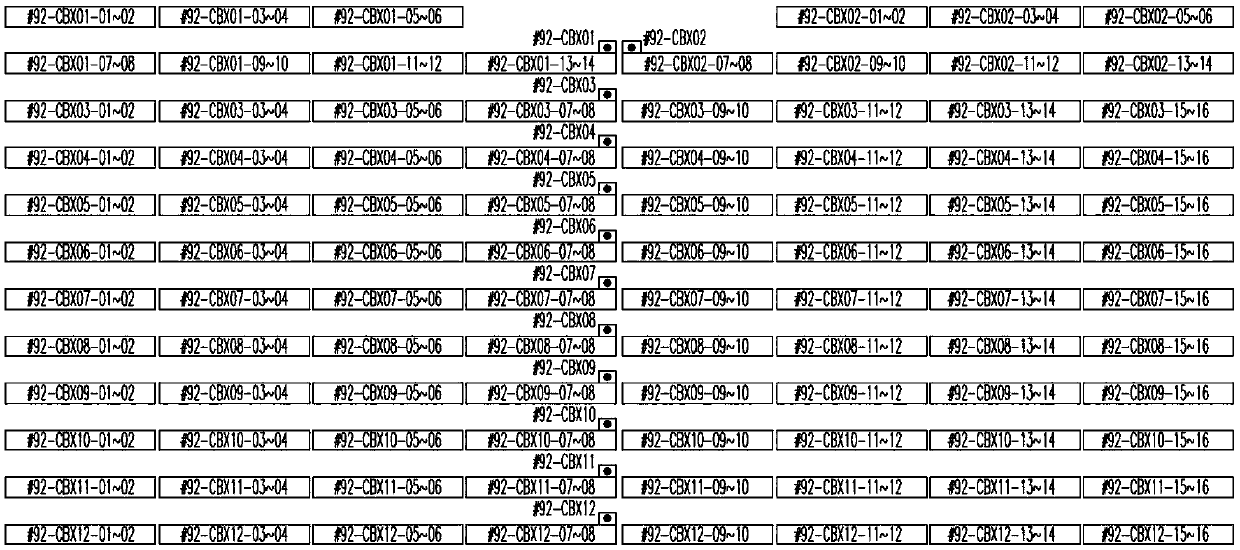

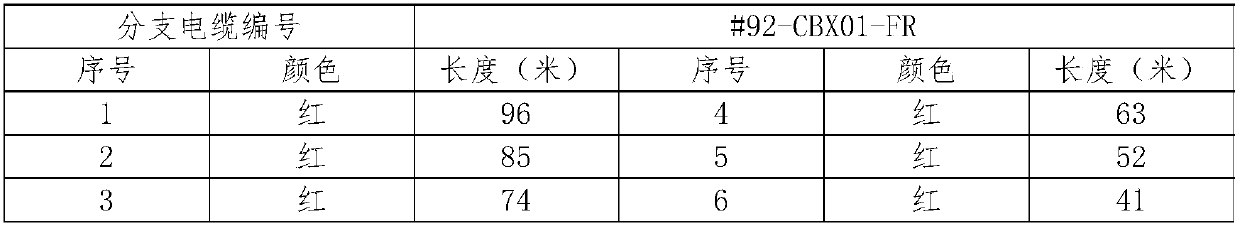

[0022] S2. Export the PV cable parameters and process them. According to the distribution of the combiner boxes in different areas, compile the PV cable cutting table; the 1# and 2# combiner boxes in the standard area 1 are grouped according to the front row and the rear row, and the red and black lines are arranged. , 3#-12# combiner boxes are grouped according to the left side and right side, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com