Anti-blocking back-washing adjustable micro spray nozzle

A technology of a micro-spray head and a micro-spray head, which is applied in the direction of spraying devices, spraying devices, etc., can solve the problems that the spraying angle of the water spray head cannot be adjusted, reduce the growth speed of the plant, and affect the growth of the plant, so as to achieve a simple structure and improve irrigation. Efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

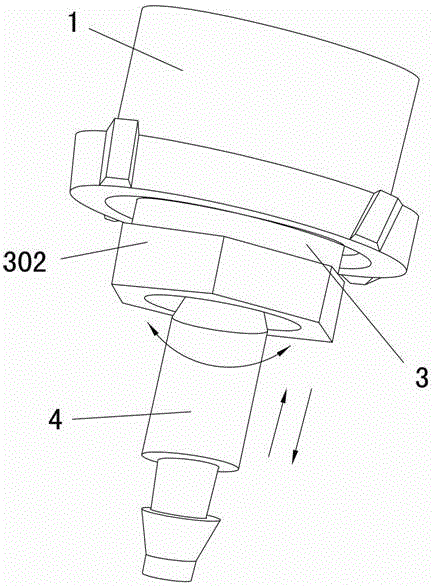

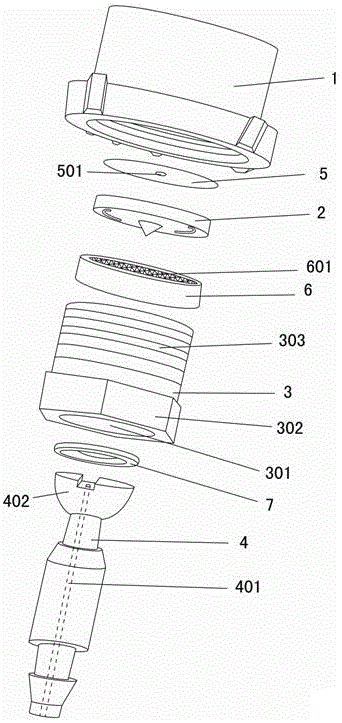

[0013] Such as Figures 1 to 4 As shown, the anti-clogging and backwashing adjustable micro-spray head proposed by the present invention includes a micro-spray head cover 1, a water separator 2, a micro-spray head base 3, a barbed joint 4, a water spray plate 5, a filter gasket 6 and O-ring seal 7.

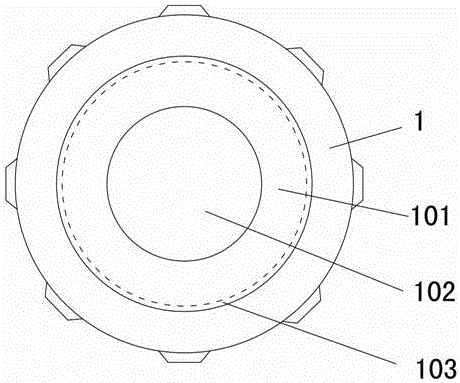

[0014] Wherein, the inside of the micro-spray top cover 1 has a cylindrical housing chamber 101, the bottom of the housing chamber 101 has a water inlet hole 102 with an inner diameter smaller than the inner diameter of the housing chamber, and the inner wall of the housing chamber 101 has an internal thread structure 103.

[0015] The water diversion sheet 2 is put into the housing cavity 101, and the water diversion sheet 2 is provided with a pair of water passing grooves 201 passing through the water diversion sheet, and the end surface of the water diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com