Lifting device for train non-pulling wheel flaw detection

A lifting device and train technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of lifting height of lifting device, unbalanced use cost of layout structure, occupying more layout space, complex structure of lifting device, etc., and achieving strong lifting force. , to ensure the effect of easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

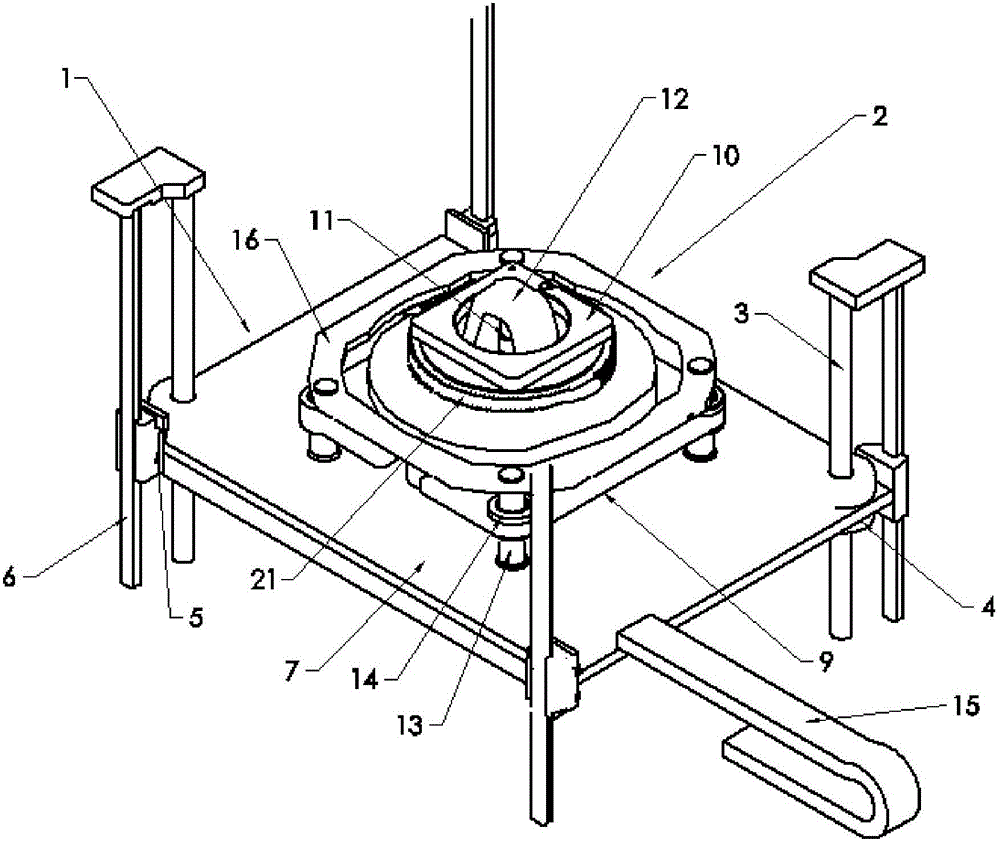

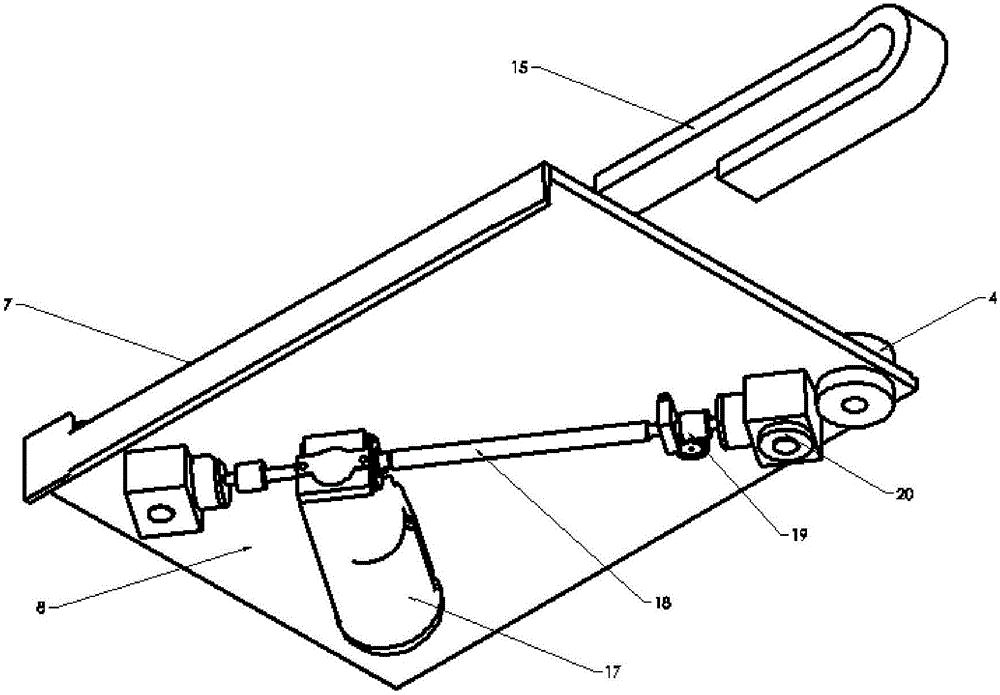

[0021] Such as figure 1 , figure 2 As shown, a lifting device for flaw detection of trains without falling wheels includes a screw lifting mechanism 1, a hydraulic lifting mechanism 2. The screw lifting mechanism 1 includes a screw 3, a screw nut 4, and a guide slide Block 5, sliding rail 6, lifting plate 7, said screw rod 3 is connected with a guide slider 5, screw nut 4, said guide slider 3 is located on the slide rail 6, the hydraulic lifting mechanism 2 is connected to the On the lifting plate 7 of the screw lifting mechanism 1, the hydraulic lifting mechanism 2 includes a lifting platform 9, a lifting pad 10, a lifting cylinder 11, a bearing block 12, a guide shaft 13, a guide bearing 14, and the lifting pad The plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com