Air suction muffler of compressor

A muffler and compressor technology, which is applied in the field of compressors, can solve problems such as disintegration, cracking, and rubber swelling, and achieve the effects of high efficiency, stable performance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

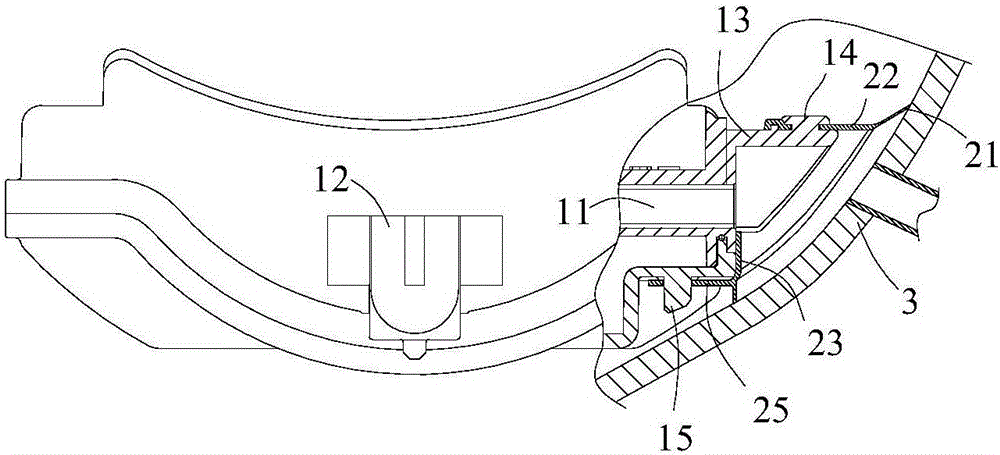

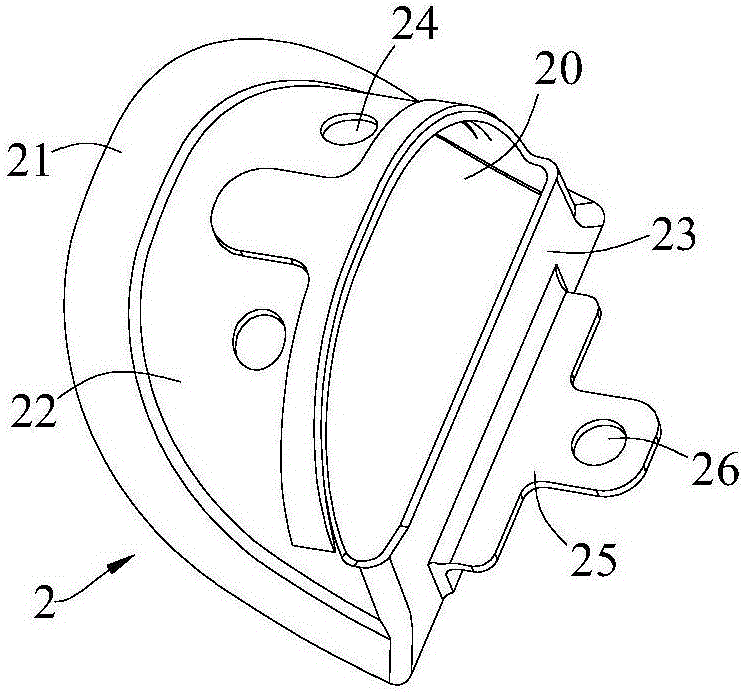

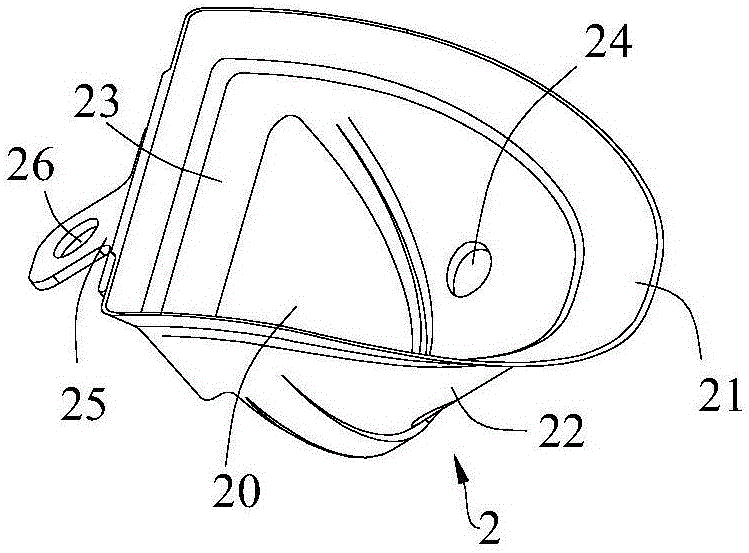

[0021] refer to Figure 1 to Figure 7 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0022] The present invention provides a compressor suction muffler, comprising a muffler body 1 and a connector 2, the muffler body 1 is provided with an air inlet 11 and an air outlet 12, and the muffler body 1 has a muffler cavity inside, the muffler body 1 The connector 2 is located at the air inlet 11. The connector 2 is made of super-tough plastic. The edge of the outer ring of the connector 2 forms a flexible, continuous and flat lip 21 by controlling the thickness. The muffler body 1 can pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com