Fixing part resistance structure of welded meshes

A technology of welding mesh and resistance structure, applied in the direction of connecting components, thin plate connection, mechanical equipment, etc., can solve the problems of metal sheet deformation, fixing parts falling off, mesh shaking, etc., to increase friction and avoid top pressure deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

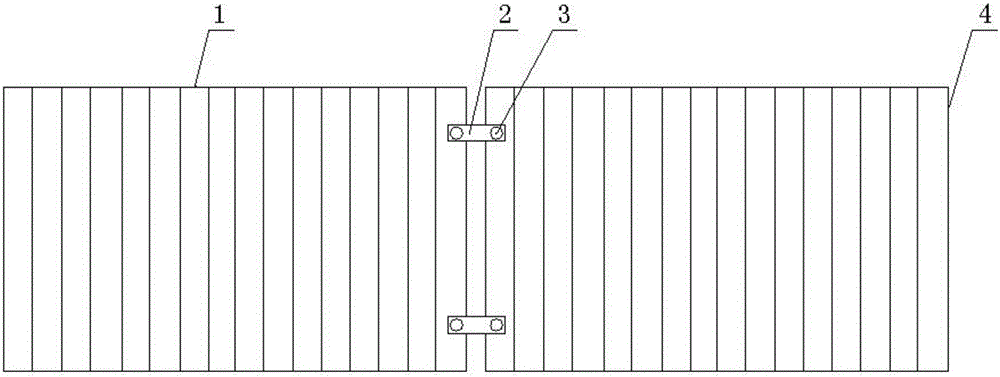

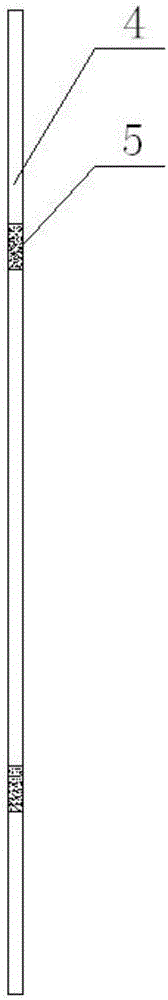

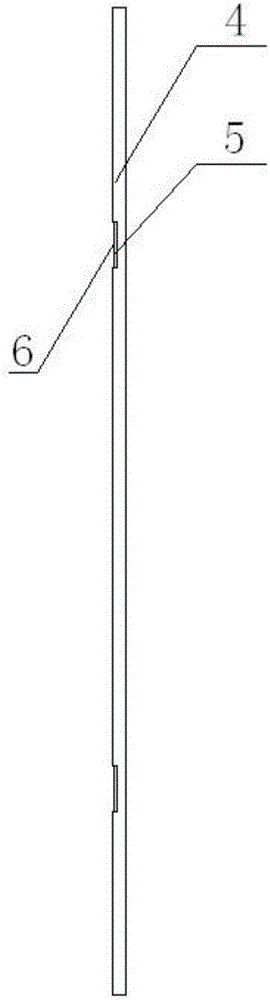

[0013] A resistance structure of a fixing part of a welded mesh, the limit structure is used for two adjacent welded meshes 1 on the guardrail net, and the spokes 4 of the fixing part 2 to be installed on the welded mesh are provided with surface contact with the fixing part The wide surface of the wide surface is provided with a limit groove 6, and the surface of the groove is provided with a pitted surface 5. There are two wide surfaces, including an upper contact surface and a lower contact surface, which are arranged on the upper surface and the lower surface of the spoke, and the spoke It is the spoke of two adjacent welded mesh sheets which are close to the other side of the welded mesh sheet, and is located at the side end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com