Touch panel and manufacturing method therefor as well as touch apparatus

A technology of touch panel and production method, which is applied in the direction of instruments, electrical digital data processing, input/output process of data processing, etc., can solve the problems of active pen signal attenuation, etc., achieve good effect and reduce attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

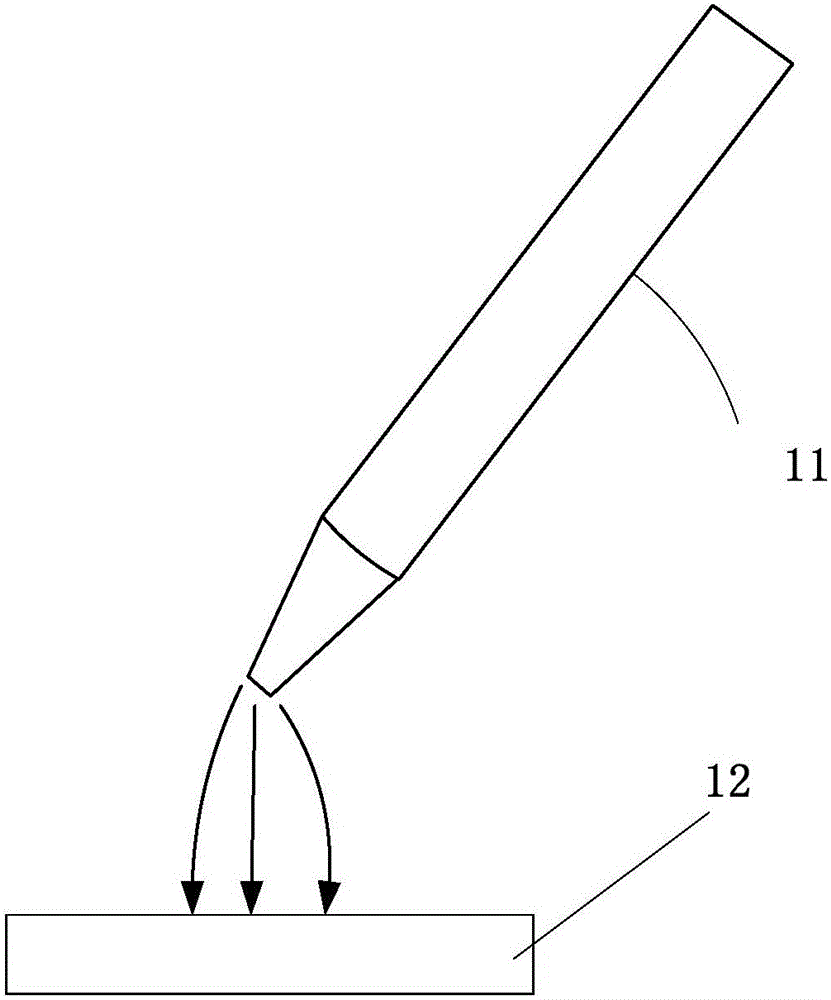

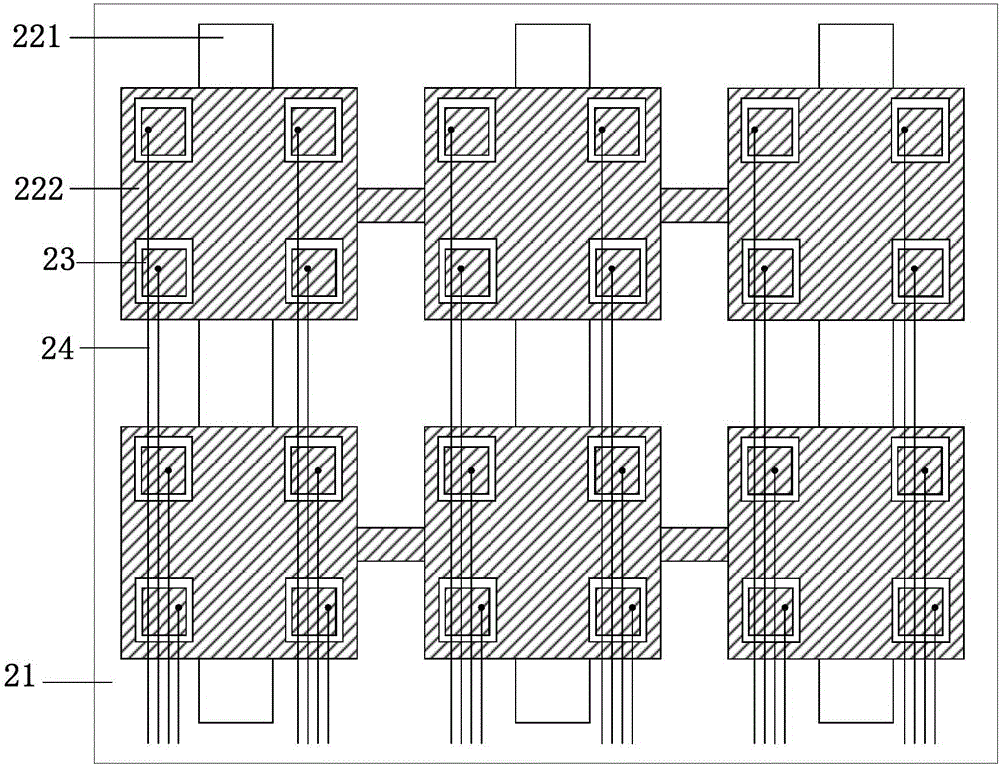

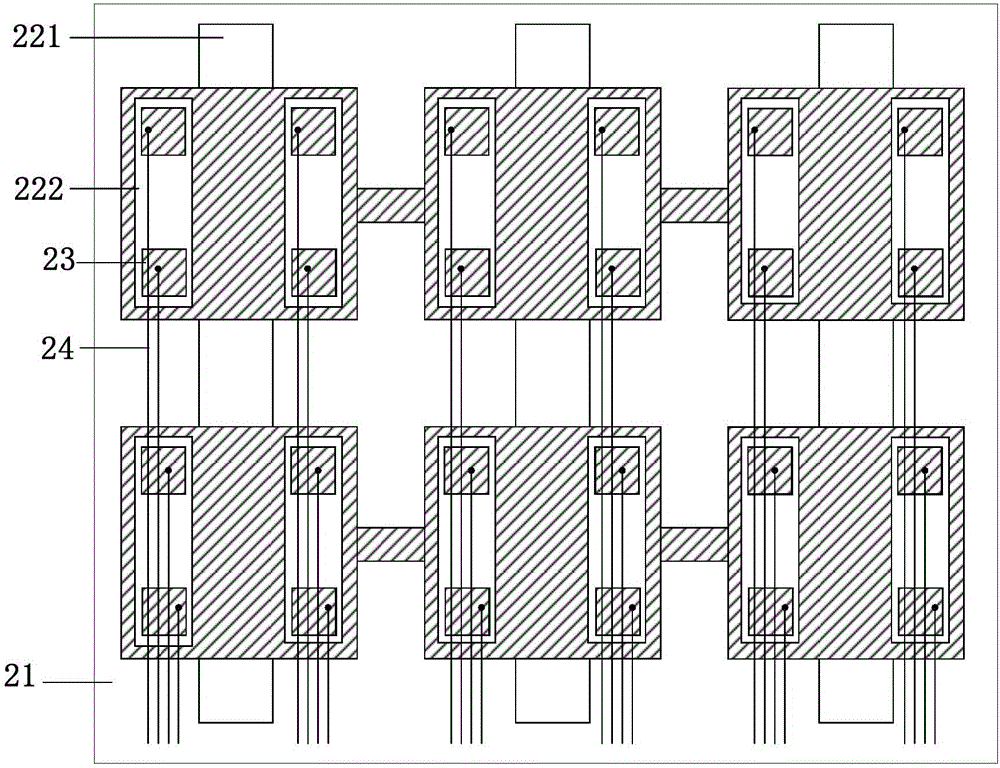

[0040] An embodiment of the present invention provides a touch panel, including a base substrate, a plurality of touch electrodes and a plurality of active pen electrodes disposed on the base substrate, wherein the size of the active pen electrodes is smaller than that of the touch The size of the control electrode.

[0041] In the embodiment of the present invention, in the touch panel, the active pen electrode is separately set as the receiving electrode of the active pen, instead of using the existing touch electrode as the receiving electrode of the active pen, because the size of the active pen electrode is smaller than the touch electrode Therefore, compared with the touch electrodes, the RC loading of the active pen electrode is very small, thus, the attenuation of the active pen signal can be reduced, and the active pen touch is more sensitive and the effect is better.

[0042] If the touch panel is an in-cell touch panel, when the touch electrodes of the in-cell (In C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com