Hollow thin electric conduction link

A conductive slip ring and hollow technology, which is applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of restricting the functions of application equipment, restricting the continuous rotation function, and only rotating within 360 degrees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

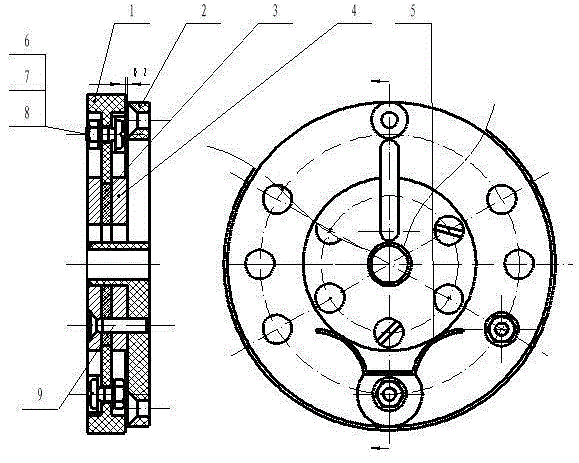

[0012] In the inner ring of the fixed ring (1) of the conductive slip ring, an insulating connecting piece (3) is arranged, and the connecting piece and the fixed ring (1) can rotate relatively and are constrained radially by the structure of the fixed ring (1); the insulating connecting piece (3) Two collector rings (4) fixedly connected with the moving ring (2) are installed at both ends, and the collector ring-connecting piece-collector ring-moving ring are connected and fixed in sequence with screws (9) , which forms the constraint of the fixed ring on the collector ring (4) and the moving ring (2) in the axial direction, and constitutes a relatively rotatable fixed ring and moving ring combination structure. The hollow hole and the long waist hole on the moving ring are namely Be the channel for the expansion wire.

[0013] On the fixed ring (1), fix and install the brush (5) which is in sliding contact with the collector ring (4) with screws (6), gaskets (7), and nuts (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com