Fixing mechanism for terminal strip of switch cabinet and meter room

A fixing mechanism and terminal fixing technology, applied in substation/switch layout details, substation/switchgear board/panel/desk, electrical components, etc., can solve problems such as unfavorable wiring installation, inconvenient, unsightly, etc., to achieve convenience The effect of wiring, easy maintenance, and aesthetic improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

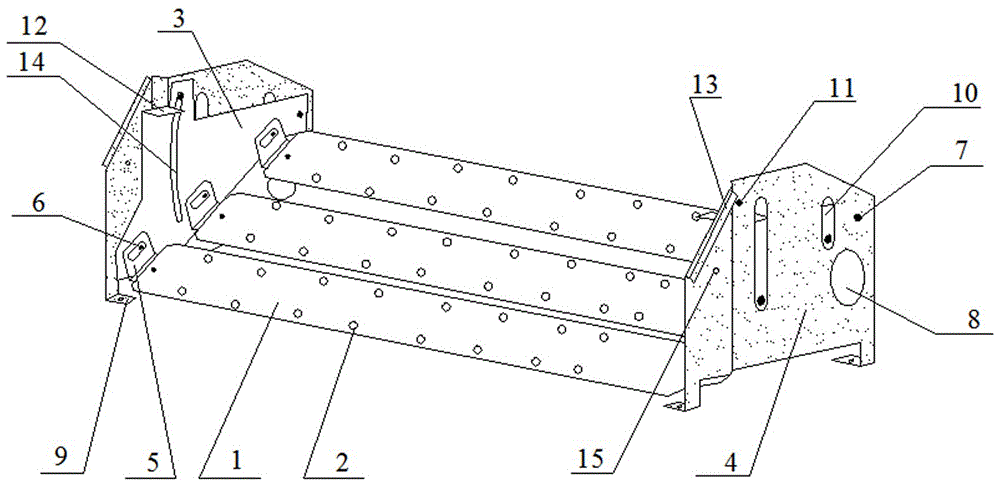

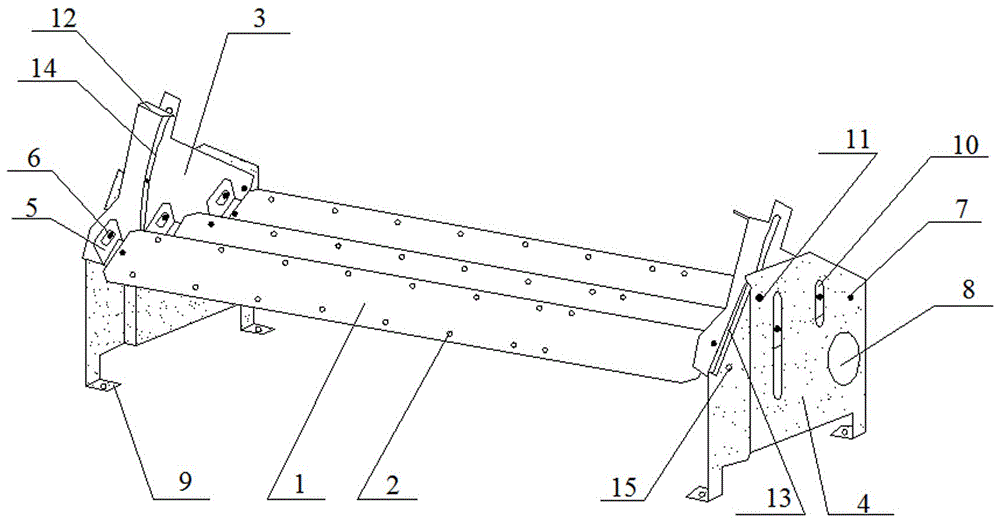

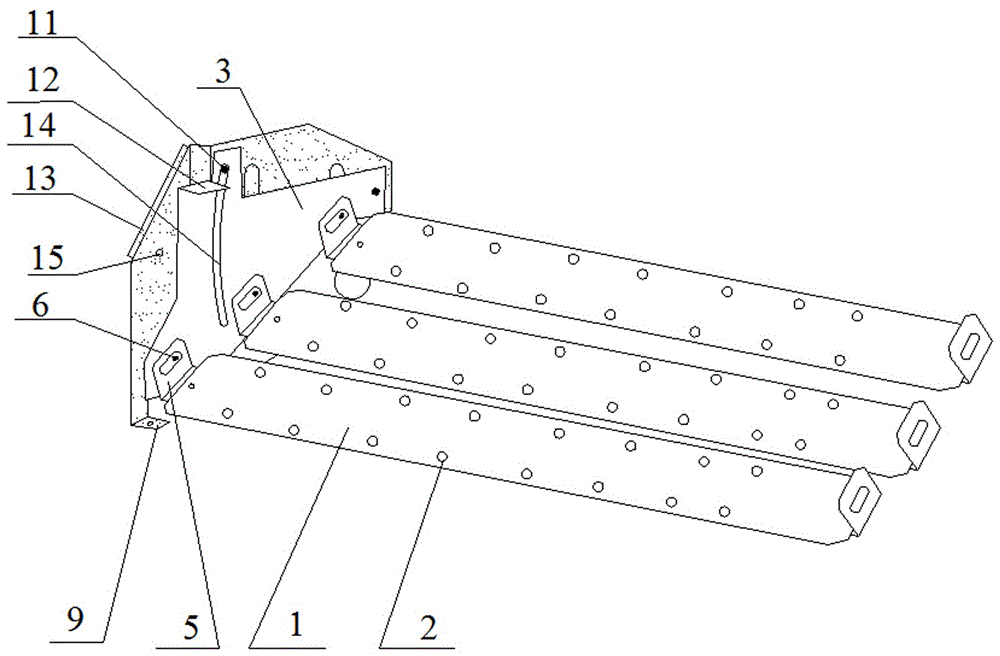

[0019] Such as figure 1 As shown, a terminal row fixing mechanism for the instrument room of a switchgear includes three rows of terminal fixing plates 1 composed of a front terminal fixing plate with a wire binding hole 2, a middle terminal fixing plate and a rear terminal fixing plate, located on the terminal fixing plate 1 Two ends and left and right symmetrical lifting brackets 3 and support plates 4, the support plate 4 is provided with a wire hole 8, the bottom is provided with a foot 9 with a mounting hole and an anti-scratch fold 13, and the support plate 4 is provided with The strip hole 10 for the screw end of the elastic bolt 6 to pass through, the support plate 4 has an outward expansion surface, that is, the cross section of the support plate 4 on the left side of the terminal fixing plate 1 is " " shape, the cross-section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com