Method and apparatus for 3d printing with climate controlled processing

A kind of equipment, 3D technology, applied in the direction of metal processing equipment, chemical instruments and methods, 3D object support structure, etc., can solve the problems of negative impact and limitation of economic feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

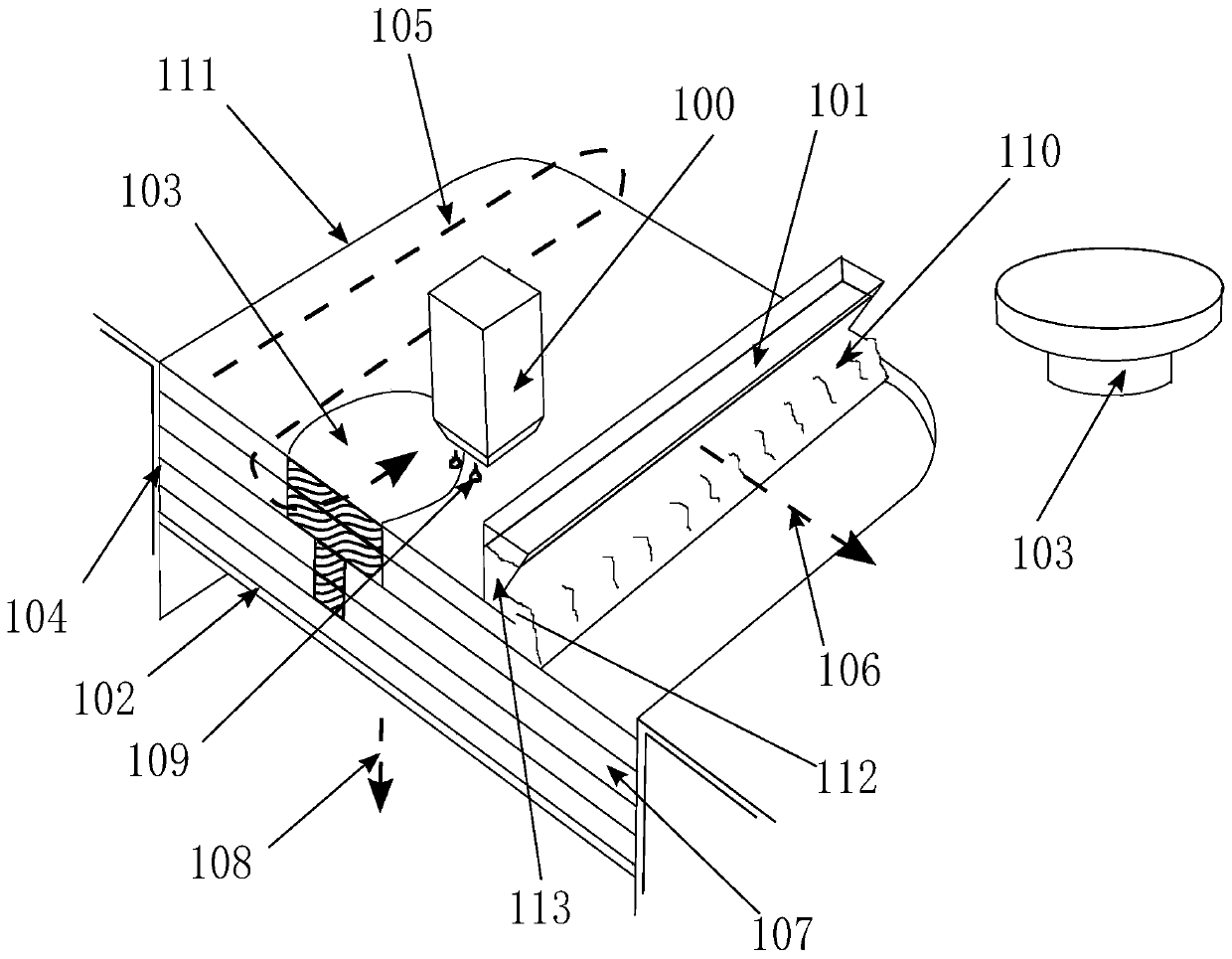

[0072] Other preferred specific embodiments are described below.

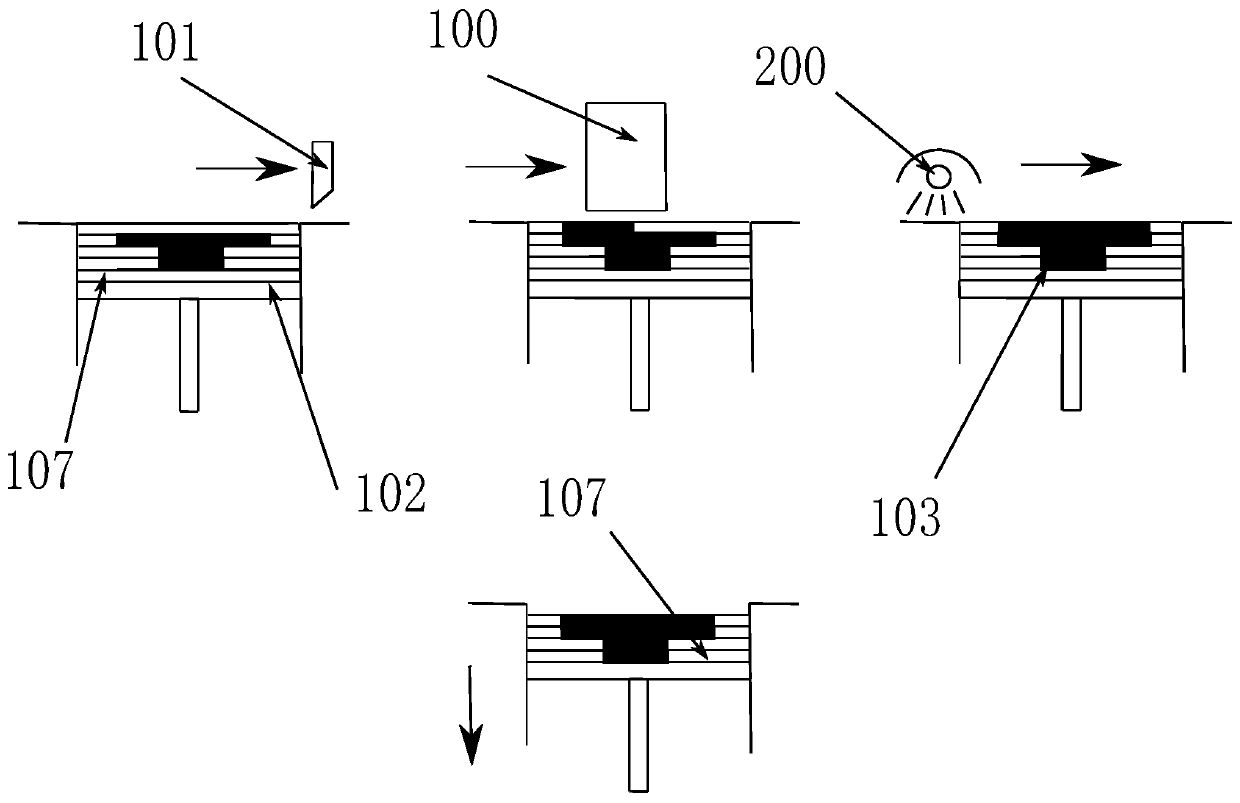

[0073] The basic components correspond to systems for layer-by-layer construction of models by means of inkjet printing technology, as known to those skilled in the art, and therefore need not be repeated here in great detail.

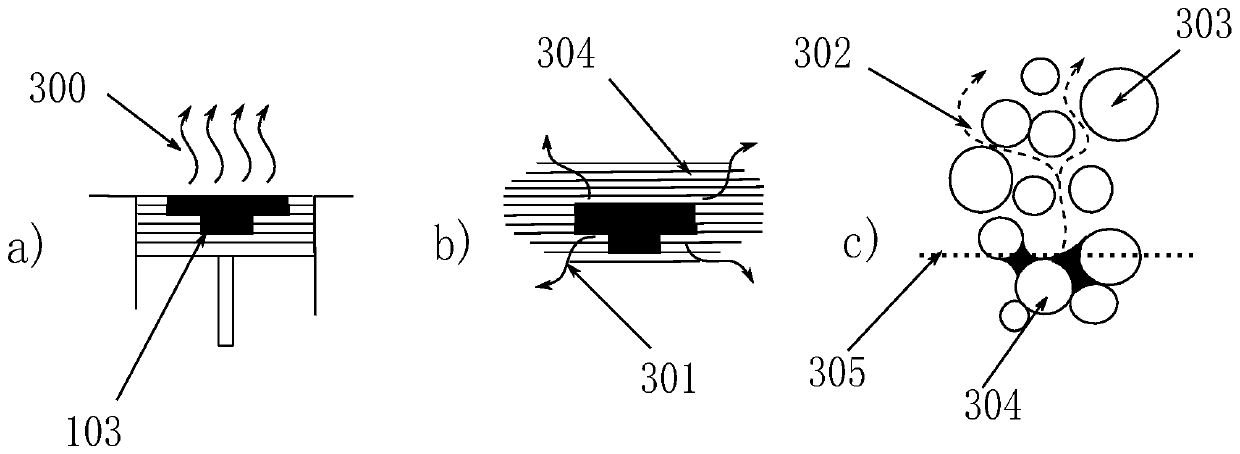

[0074] The sequence is preferably organized as follows: A layer of granular material is applied to the build platform and smoothed out. The printing liquid is then printed onto layers according to the layer data of the 3D model. A substantial part of the material used to bind the granules is provided in the powder in the form of dry granules. The dissolution process can now be accelerated by heating with IR lamps. After printing and heat treatment, the build platform is lowered and the process begins again.

[0075] These steps are repeated until the part is fully present in the constructed cake.

[0076] The quality of components produced in this way is evaluated on the basis of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com