Stage dry ice smoke machine

A technology of fog machine and dry ice, which is applied to stage devices, entertainment, and devices used in theaters and circuses, etc. It can solve the problems of shortened service life, high power consumption, safety accidents, etc., and achieves the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

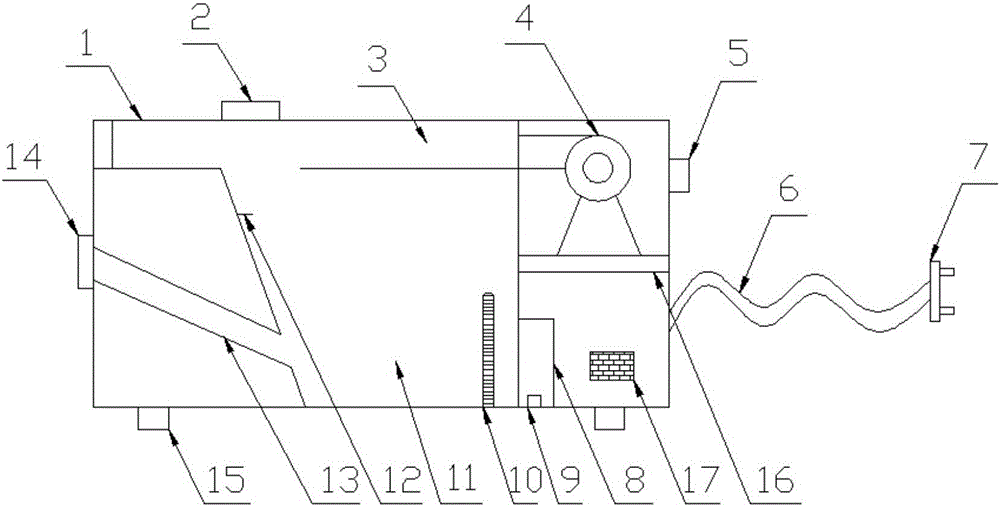

[0018] Such as figure 1 As shown, the present invention provides a stage dry ice fog machine, including a fog machine body 1, a water inlet cover 2, an air duct 3, a fan 4, a main control switch 5, a connecting wire 6, a plug 7, a heater 8, a heating switch 9, Thermometer 10, water storage tank 11, warning line 12, adding ice pipeline 13, adding ice cover 14, column 15, support plate 16 and warning device 17, the top of fog machine body 1 is provided with water inlet cover 2, and the top of water inlet cover 2 An air duct 3 is provided below, and a water storage tank 11 is provided below the air duct 3. A thermometer 10 and a warning line 12 are provided on the surface of the water storage tank 11. One side of the water storage tank 11 is connected with an ice adding pipeline 13, and the ice adding pipeline 13 One end is provided with an ice cap 14, the other side of the water storage tank 11 is provided with a heater 8 and a support plate 16, the surface of the heater 8 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com