Automatic bolt locking machine

A bolt machine and automatic locking technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large production line area and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

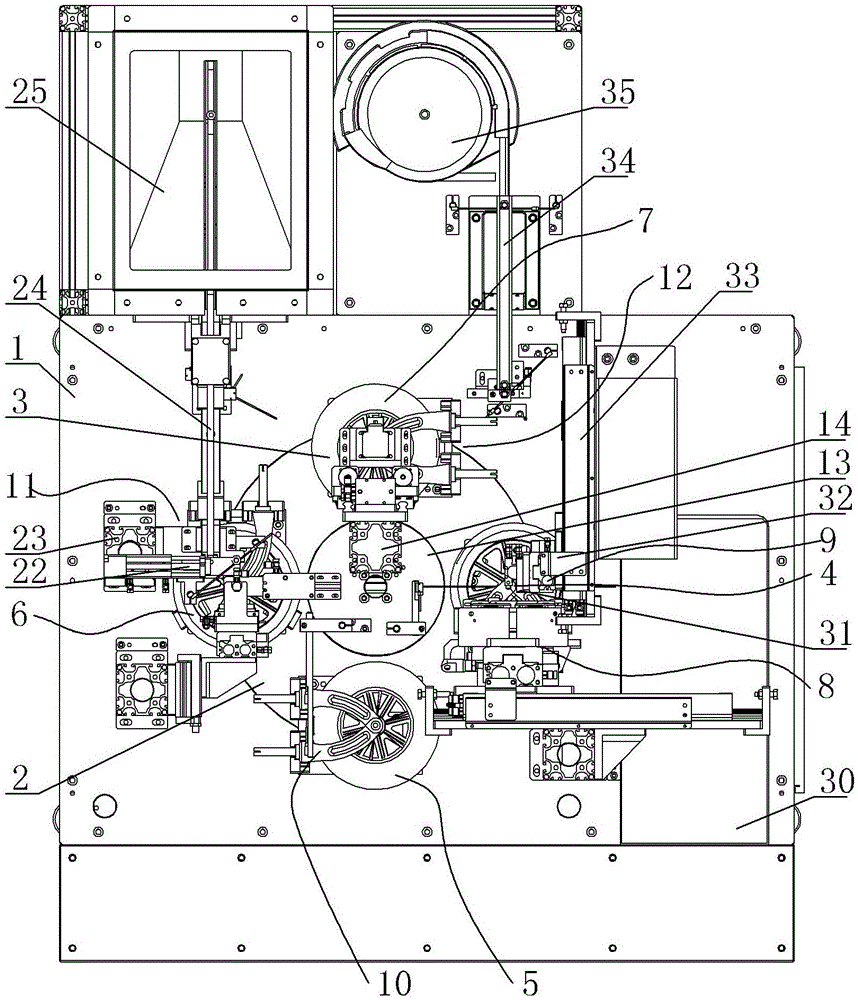

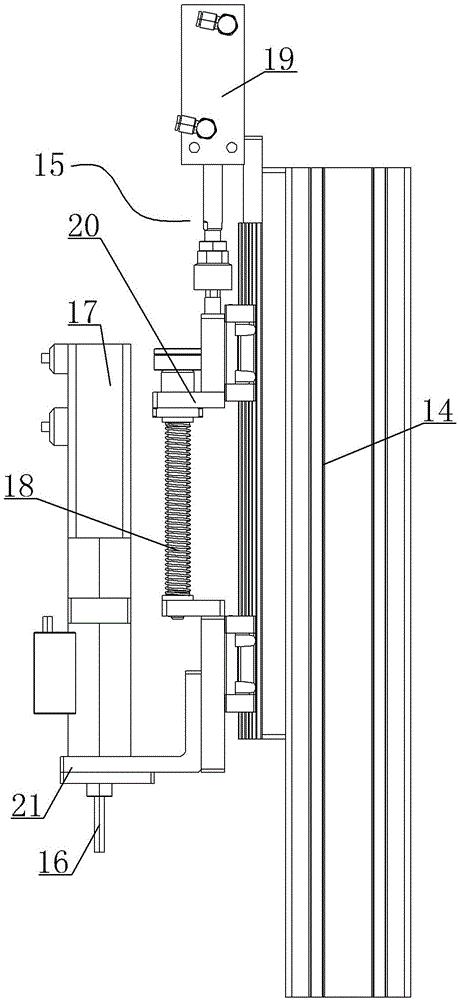

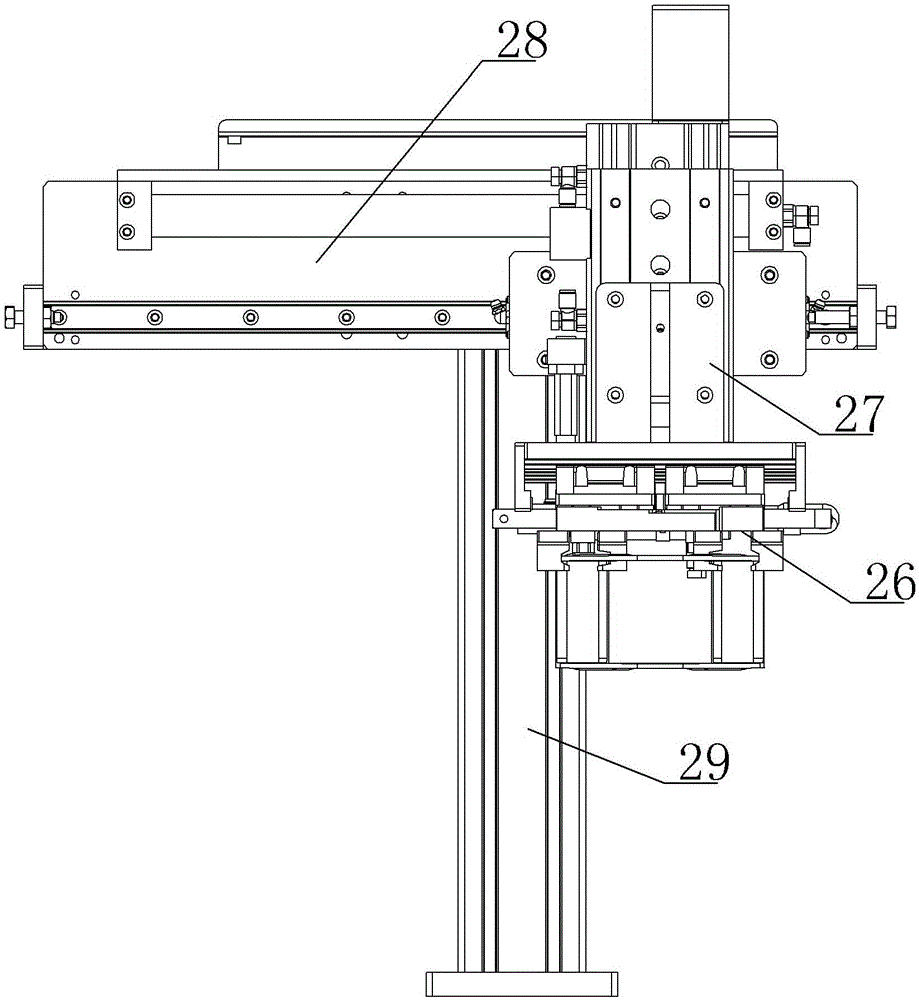

[0018] A kind of automatic locking bolt machine, see Figure 1 ~ Figure 2 : It includes a frame 1, the upper center of the frame 1 is provided with a closed circular track 2, four clamp structures 3 are evenly distributed on the circular track 2, and the bottoms of the four clamp structures 3 are respectively embedded in the circular The corresponding movable components on the track 2, the rotation direction of the circular track 2 is sequentially provided with the first station 4, the second station 5, the third station 6, and the fourth station 7, and the four fixture structures 3 correspondingly stay in the Corresponding station positions, the first station 4 is specifically the finished product blanking station 8 and the nut loading station 9, and the finished product blanking station 8 is arranged on one side of the fixture structure 3 staying at the first station 4, The nut feeding station 9 is arranged on the other side of the fixture structure 3 that stays at the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com