Turning plate type bidirectional sand discharging and removing device of track sand removing vehicle for both roads and railways

A road-rail dual-purpose, flap-type technology, applied in track cleaning, cleaning methods, construction, etc., can solve the problems of worn-out railway infrastructure, non-functioning, major traffic accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

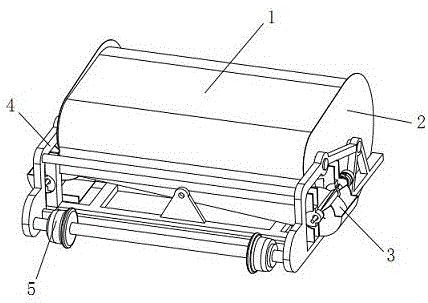

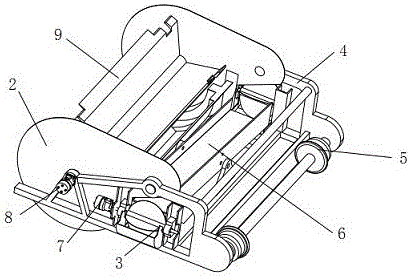

[0027] Embodiment one: if Figure 1-2 As shown, the present invention discloses a flip-type two-way sand removal device for a road-rail dual-purpose rail sand removal vehicle, including a frame 4, a sand collection part, a flip-type sand discharge part and a guide part, and the frame 4 is used for For carrying and connecting the driving device, the sand collection part is located at the front end of the frame 4, the flip-type sand discharge part is located behind the sand collection part and is used to accept the accumulated sand transported by the sand collection part, and the guide part is located at the frame 4 rear end, the frame structure of this embodiment is shown in the attached Image 6 , which is a symmetrically installed frame structure, which is mainly used to install auxiliary structures and connect the driving device when in use. The driving device can be used in conjunction with the applicant's previously applied invention patent "Rotary and Railway Dual-purpose...

Embodiment 2

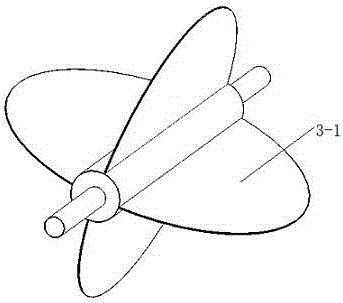

[0031] Embodiment two: the difference between the present embodiment and embodiment 1 is that the structure of the sand discharge part is different (see the attached Figure 7-10 ), the sand guide flap in this embodiment is a sand guide plate 10, the two sides of the middle part of the sand guide plate 10 are connected with the support by means of a rotating shaft, the two sides of the sand guide plate 10 are provided with upwardly protruding edges, and the two sides of the sand guide plate 10 Two upside-down triangular baffles 11 are respectively arranged on the upper side, and the top corners of the triangular baffles 11 are fixedly connected to the support, and the top edge of the triangular baffle 11 located on the inner side is close to the output end of the sand collecting part, and the sand blowing part 3 includes Sand blowing support, sand blowing wheel 3-1, sand blowing motor 7, sand blowing guide groove 3-2 and sand holding tank (see attached Figure 12 ), the sand h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com