Ventilation and pressure release type sound absorption and insulation barrier for high-speed railway

A technology for high-speed railways and sound barriers, applied to roads, noise absorption devices, tracks, etc., can solve problems such as operational constraints, high manufacturing costs, and limited load-carrying capacity, and achieve the requirements of reducing thickness, reducing the number of columns required, and reducing Effect of Mechanical Loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

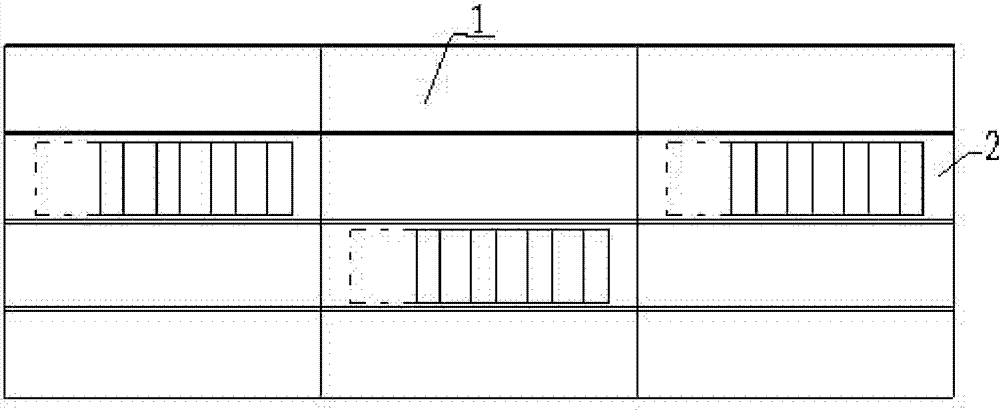

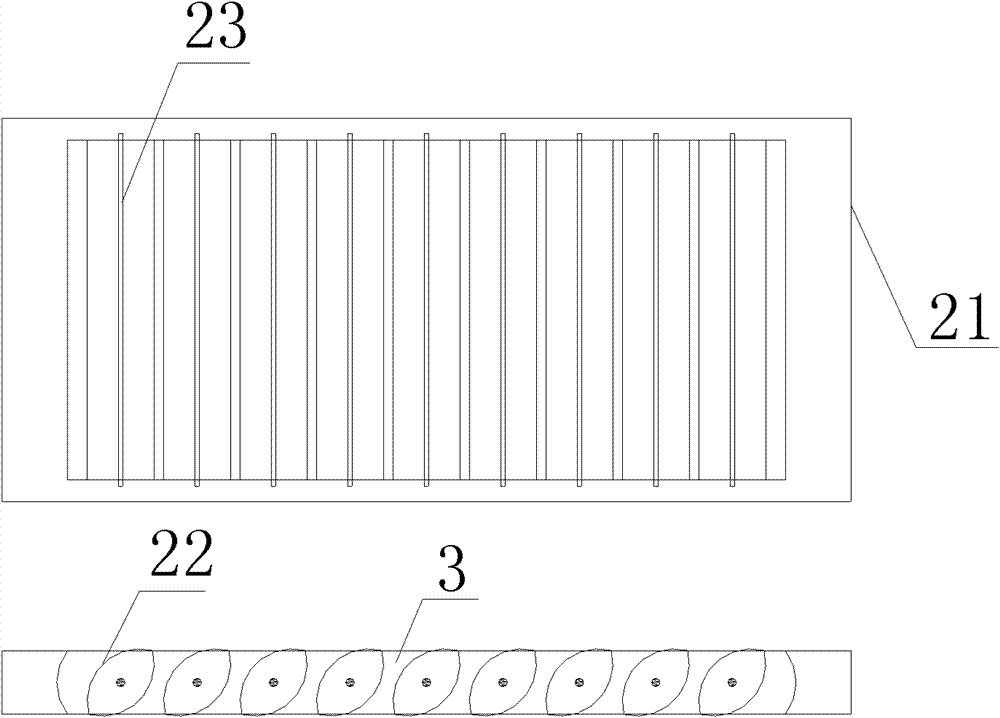

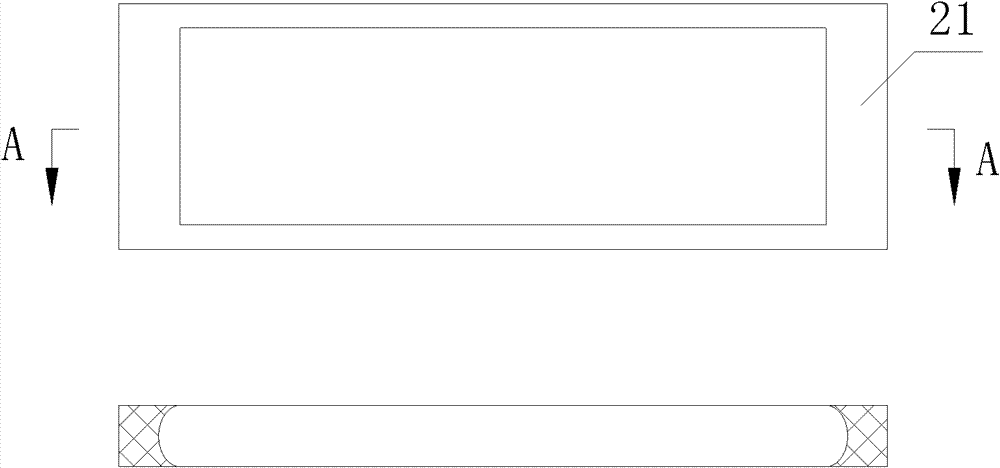

[0027] Such as figure 1 As shown in 4 to 4, the high-speed railway ventilating and pressure-relief sound-absorbing barrier of this embodiment includes a sound-barrier sound-insulation member 1 and at least three ventilating and pressure-relieving sound-barrier modules 2 combined into a ventilating and pressure-relieving sound-absorbing and insulating barrier. The pressure relief sound barrier module 2 is embedded in the sound insulation member 1 of the sound barrier, and two adjacent ventilation and pressure relief sound barrier modules 2 are misplaced in the length direction of the sound insulation member 1 of the sound barrier, that is, in the sound insulation member of the sound barrier 1 The two ventilation and pressure relief sound barrier modules 1 adjacent to each other in the length direction are not on the same straight line. On the one hand, this setting ensures the necessary flow and pressure relief area, and makes the barrier body more uniform in force; on the other...

Embodiment 2

[0030] Two adjacent ventilation and pressure relief sound barrier modules 2 are neatly and regularly arranged in the length direction of the sound barrier sound insulation member 1, that is, two adjacent ventilation and pressure relief sound barrier modules 2 are on the same horizontal line, and the rest are the same as in Embodiment 1 same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com