Composite Formwork System and Construction Method of Large Cantilever Beam and Slab

A construction method and composite technology, applied in formwork/formwork/work frame, building structure support, building structure support, etc., can solve problems such as cumbersome preloading process, hidden safety hazards, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

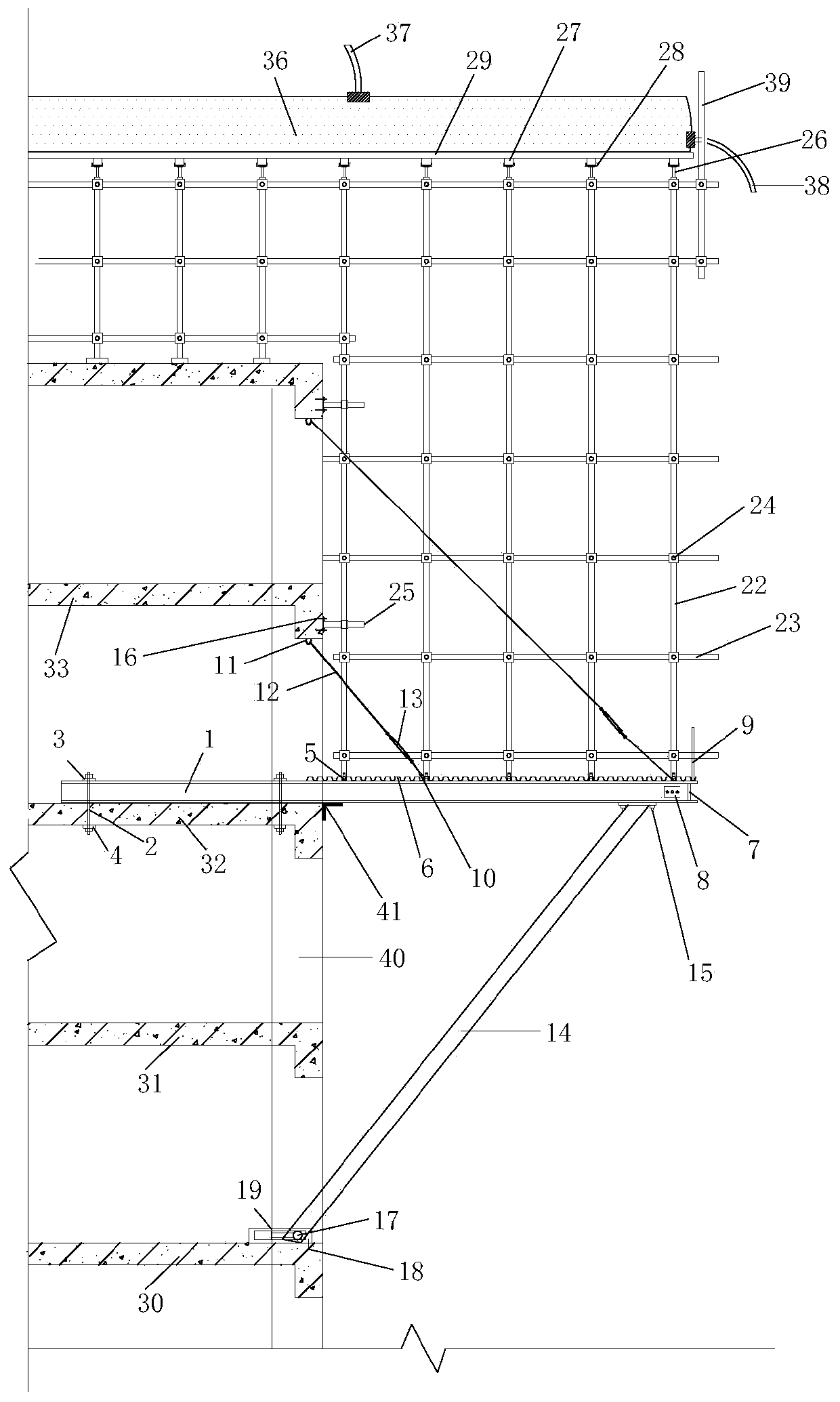

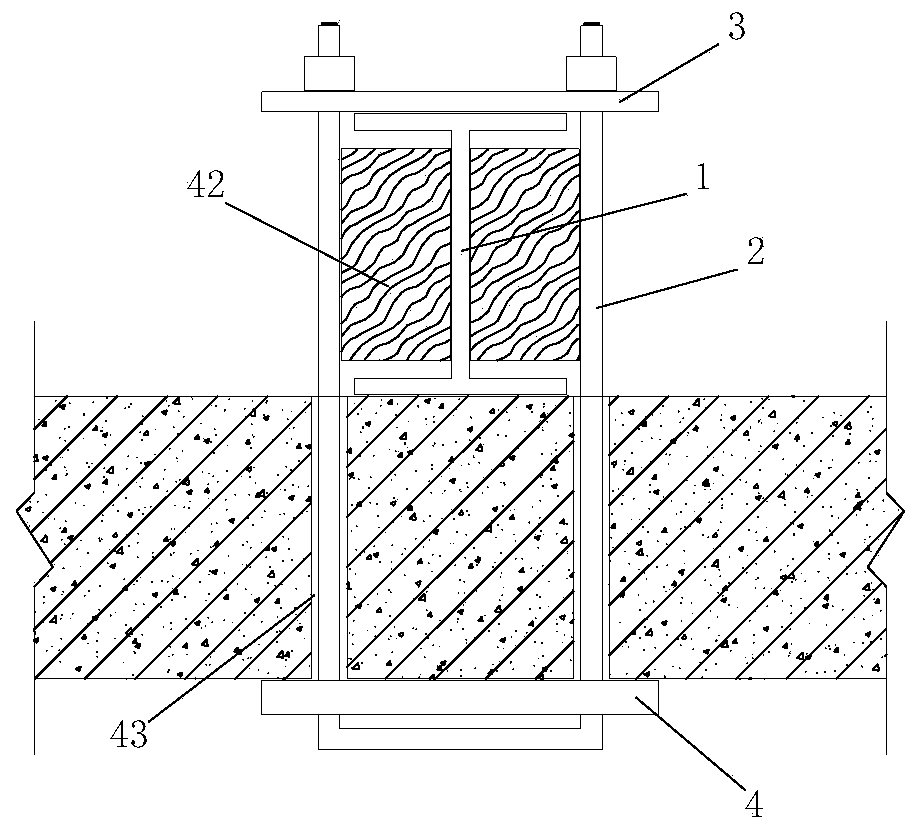

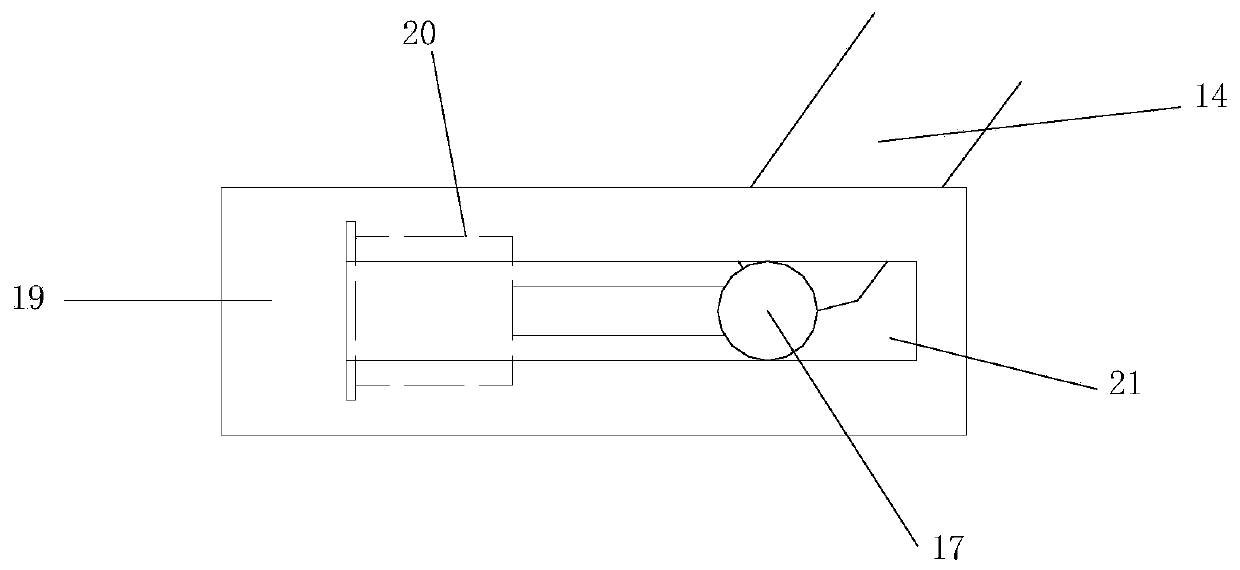

[0032] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

[0033] figure 1 It is a cross-sectional view of the preloading of the large cantilever beam-slab composite support formwork system. Such as figure 1 The large cantilever beam-slab composite formwork support system shown mainly includes: cantilever beam 1, connecting beam 7, right-angle connector 8, U-shaped bolt 2, positioning pile 5, anti-skid angle steel plate 9, diagonal brace 14, diagonal Pulling wire rope 12, bottom adjusting part 19, bottom protective plate 6, water bag 36, turnbuckle bolt 13.

[0034] Cantilever beam 1 and connecting beam 7 are made of I16 I-steel. According to general engineering needs, 3.5m, 4.5m, 6m long I16 I-steel cantilever beams are customized and painted with antirust paint and topcoat.

[0035] figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com