Welding-free and simply combined door frame combination

A combination and welding-free technology, which is applied in windows/doors, building components, buildings, etc., can solve problems such as poor layout and stacking, unreachable volume of transport vehicles, complicated manufacturing process, etc., to achieve convenient and easy handling , The structure is novel and unique, and the building volume is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention is now described in detail in conjunction with the accompanying drawings:

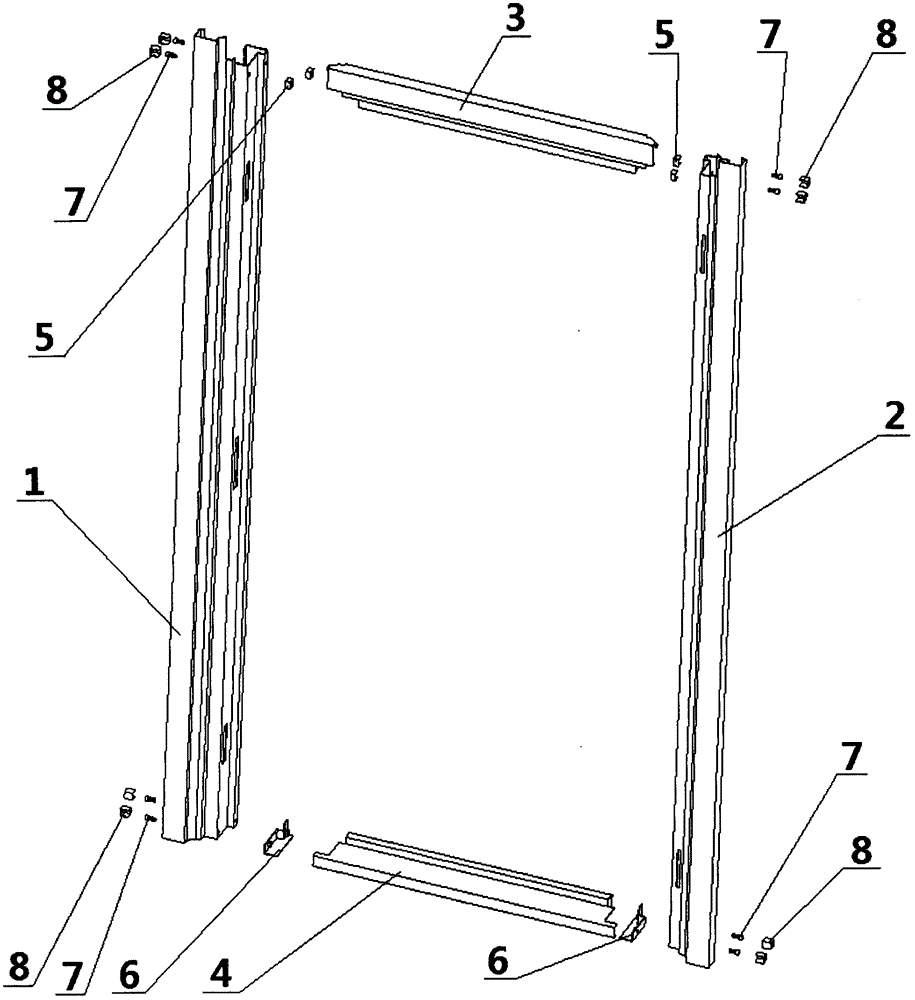

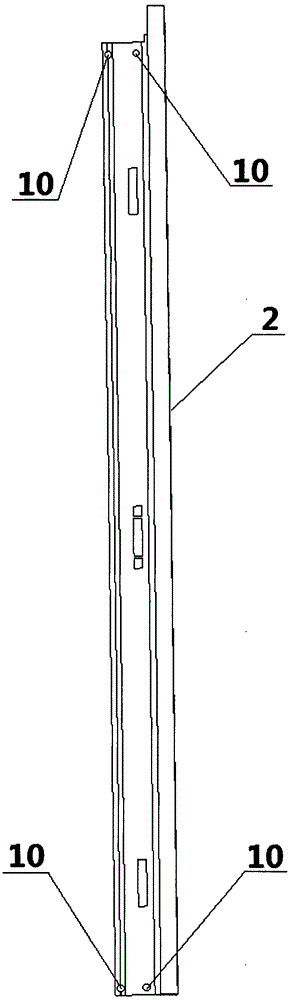

[0066] The present invention is composed of a left frame (1), a right frame (2), a top frame (3), a bottom frame (4), a top frame fixing connector (5), a bottom frame fixing connection frame (6), a hexagon socket screw ( 7), composed of inner hexagon screw cover (8).

[0067] figure 1 Shown is a schematic diagram of the structure of the present invention. Among them, 1 is the left frame, 2 is the right frame, 3 is the top frame, 4 is the bottom frame, 5 is the top frame fixing connector, 6 is the bottom frame fixing connection frame, 7 is the socket head screw, 8 is the socket head screw protection cover.

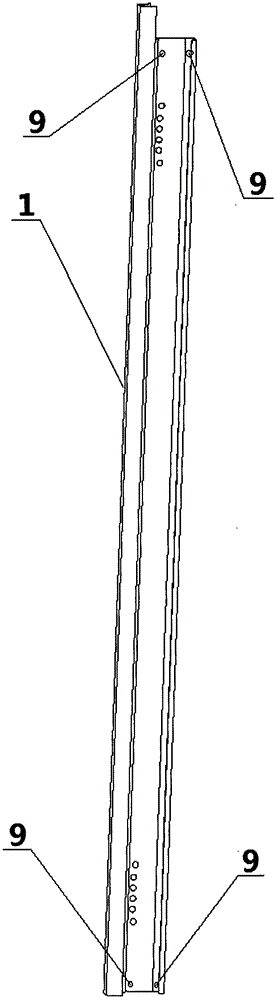

[0068] figure 2 Shown is a schematic structural diagram of the left frame (1) in the present invention. The left frame (1) is a conventional door frame frame, and two screw holes (9) are correspondingly provided at the upper and lower ends of the left frame (1).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com