Ore pulp slide damper device

A plug-in valve and pulp technology, which is applied to valve devices, valve operation/release devices, sliding valves, etc., can solve the problems that the pulp is easy to damage the rubber valve or gate valve, affect the production efficiency, increase the production cost, etc., and achieve easy control. And the effect of operation, positioning is safe and convenient, and the number of replacements is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

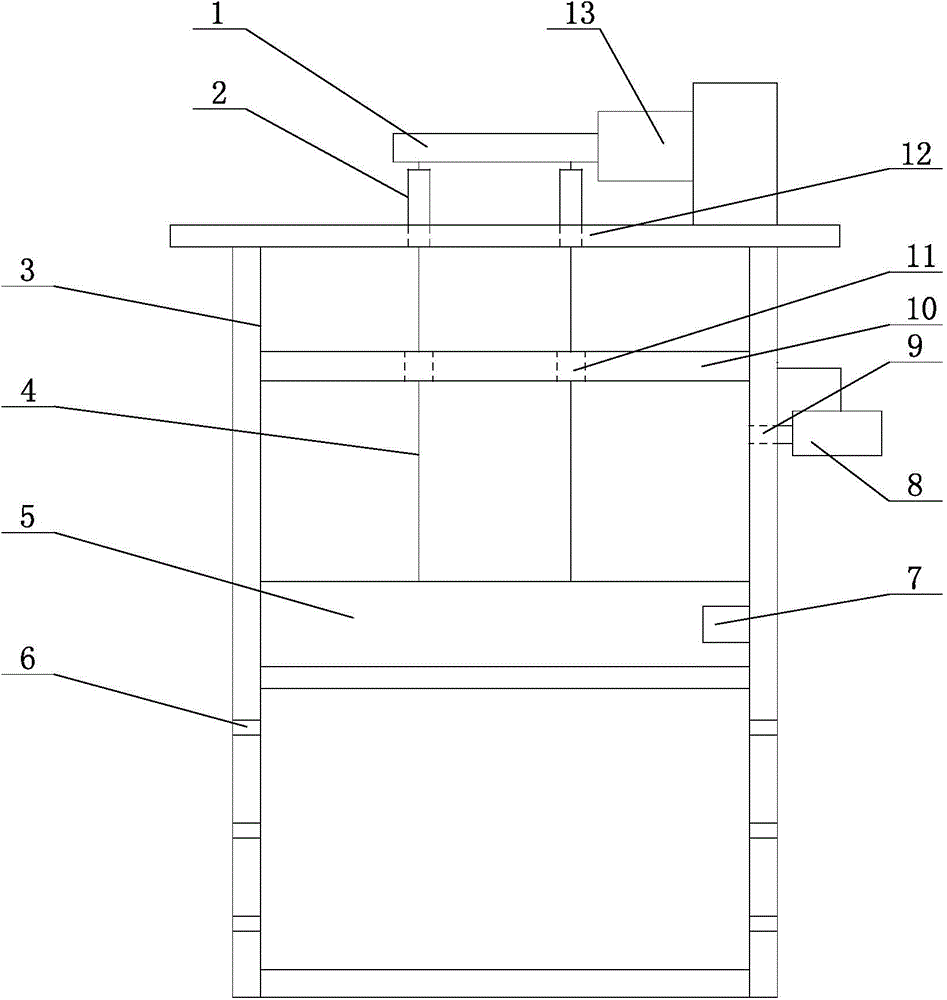

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Such as figure 1 As shown, the pulp flapper valve device of the present invention includes a bracket 3 and a valve port, a valve plate 5 is arranged in the valve port, a chute is arranged on the inside of both sides of the bracket 3, the valve plate 5 is installed in the chute, and the valve plate 5 There is a drawstring 4 on the top, the drawstring 4 is wound on the reel 1, the reel 1 is connected to the drive device 13, the drive device 13 is installed on the top of the bracket 3, the top of the bracket 3 is provided with a through hole 12 corresponding to the drawstring 4, and the valve plate 5 is provided on the side wall Positioning hole 7, partition plate 10 is set between the top plate of the valve port and the top of bracket 3, there are stay ropes passing through holes 11 distributed on the partition plate 10, positioning rod 9 is arranged below the partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com