A pipe connection device

A technology for connecting devices and pipe fittings, which is applied to indoor sanitary piping devices, water supply devices, sleeve/socket connections, etc. The effect of a large range of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

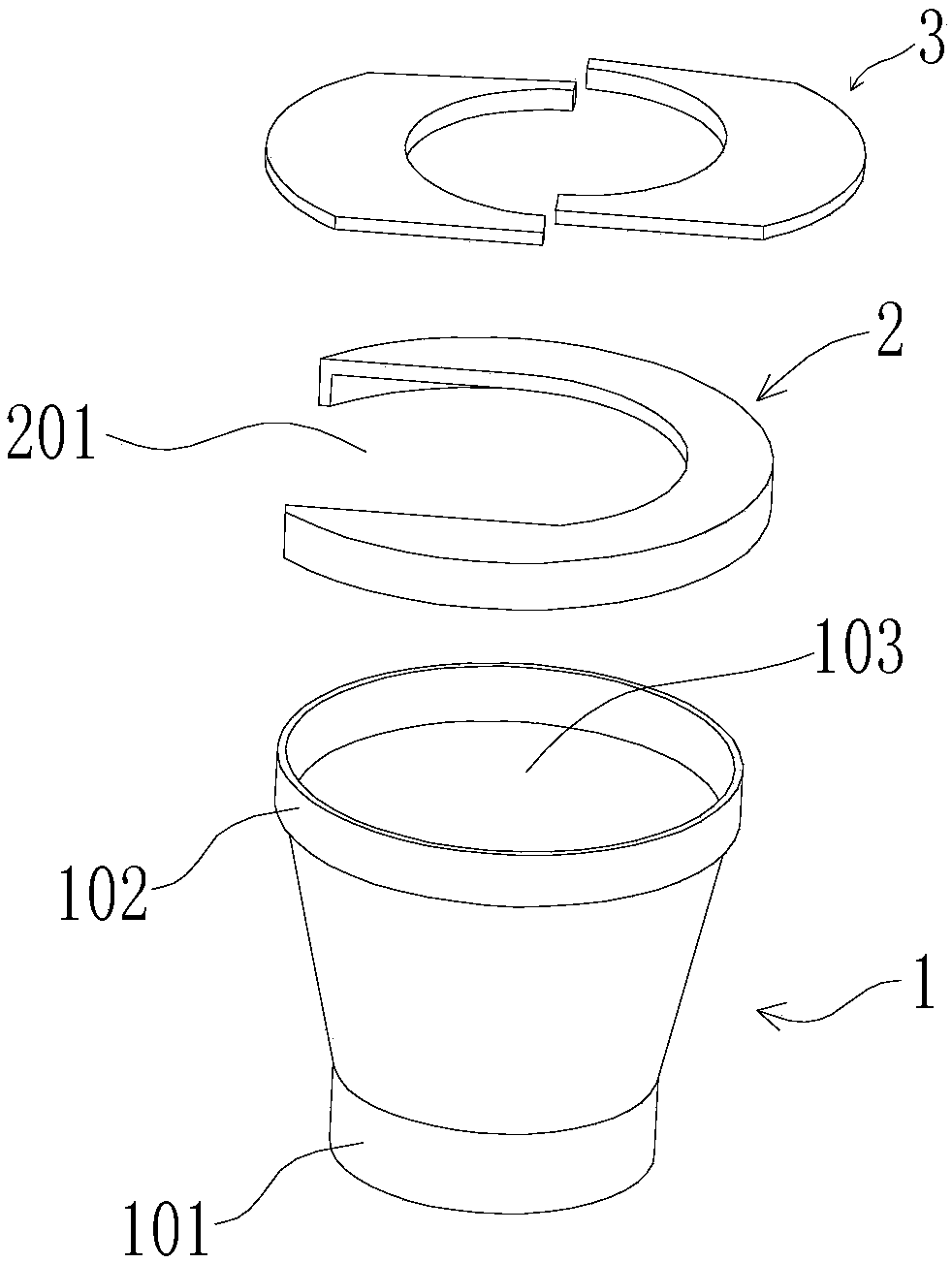

[0029] see figure 1 , figure 1 It is an exploded perspective view of Embodiment 1 of the pipe fitting connecting device of the present invention. Such as figure 1 As shown, the pipe fitting connecting device of the present invention includes a connecting body 1 connecting the upper pipe fitting and the lower pipe fitting. The connecting body 1 includes a base part 101 and an upper connecting part 102. 102 is provided with an upper connection hole 103 for connecting the upper pipe fitting and coaxially passing through the lower connection hole. The aperture of the upper connection hole 103 is larger than the aperture of the lower connection hole. Liquids such as water pass through the upper pipe fitting and the pipe fitting connecting device to reach the lower pipe fitting.

[0030] The diameter of the upper connection hole 103 is greater than the outer diameter of the upper pipe fitting. For example, the inner diameter of the upper connection hole 103 is 160mm, and the outer...

Embodiment 2

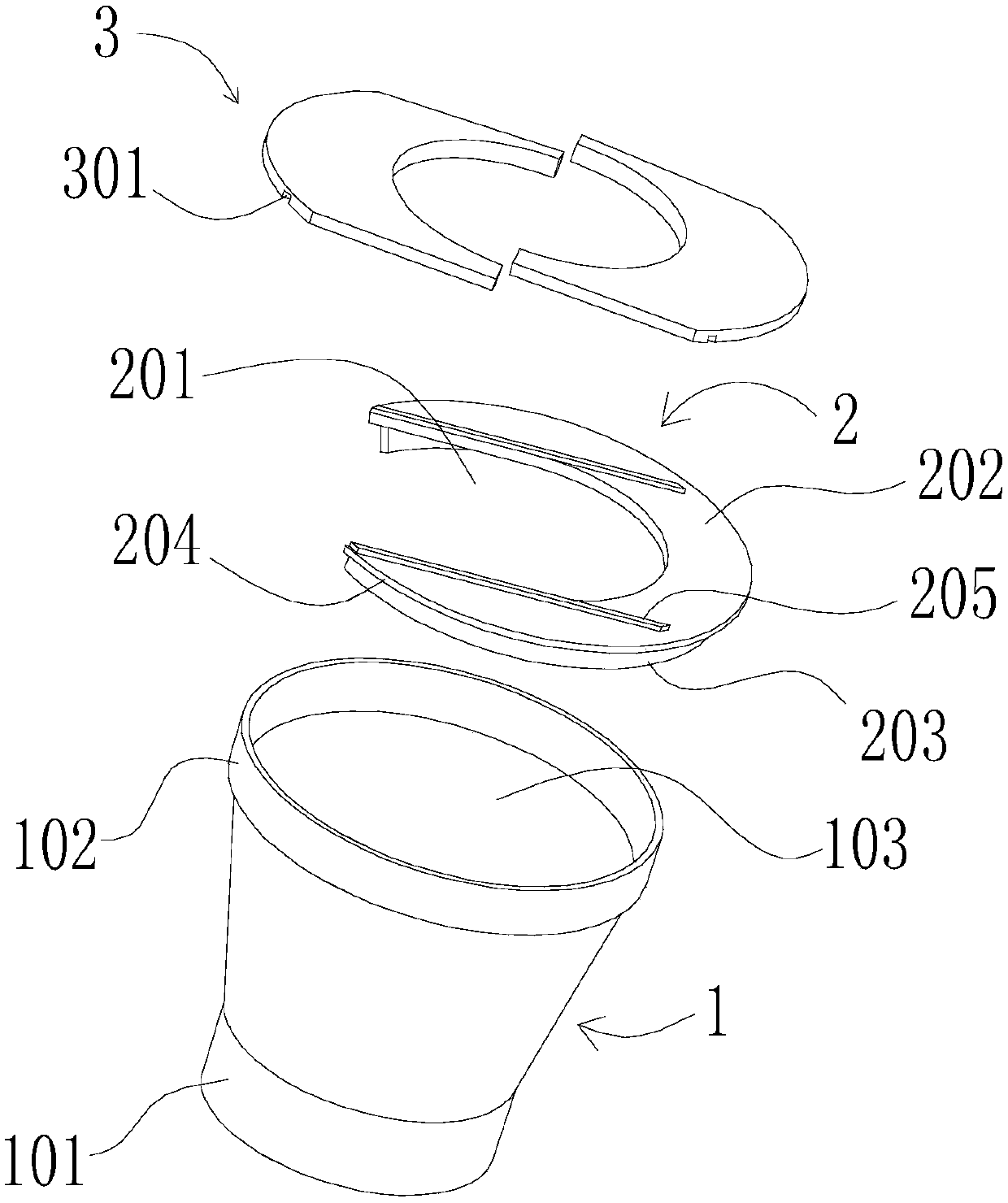

[0034] see figure 2 , figure 2 It is an exploded perspective view of Embodiment 2 of the pipe fitting connecting device of the present invention. The installation cover 2 comprises a cover surface 202 and a positioning ring 203 arranged on the lower surface of the cover surface 202. The outer diameter of the positioning ring 203 is equal to the inner diameter of the upper connection hole 103, and the positioning ring 203 is inserted in the upper connection hole 103, so that the installation cover 2 Radially fixed.

[0035] In this embodiment, in order to prevent the installation cover 2 from falling into the upper connection hole 103 in the axial direction, the edge of the cover surface 202 is expanded in the radial direction outward to form a flange 204, and the lower surface of the flange 204 is in contact with the upper surface. The upper surface of the connection part 102 is bonded. In other embodiments, the lower end of the inner wall of the upper connection hole 103...

Embodiment 3

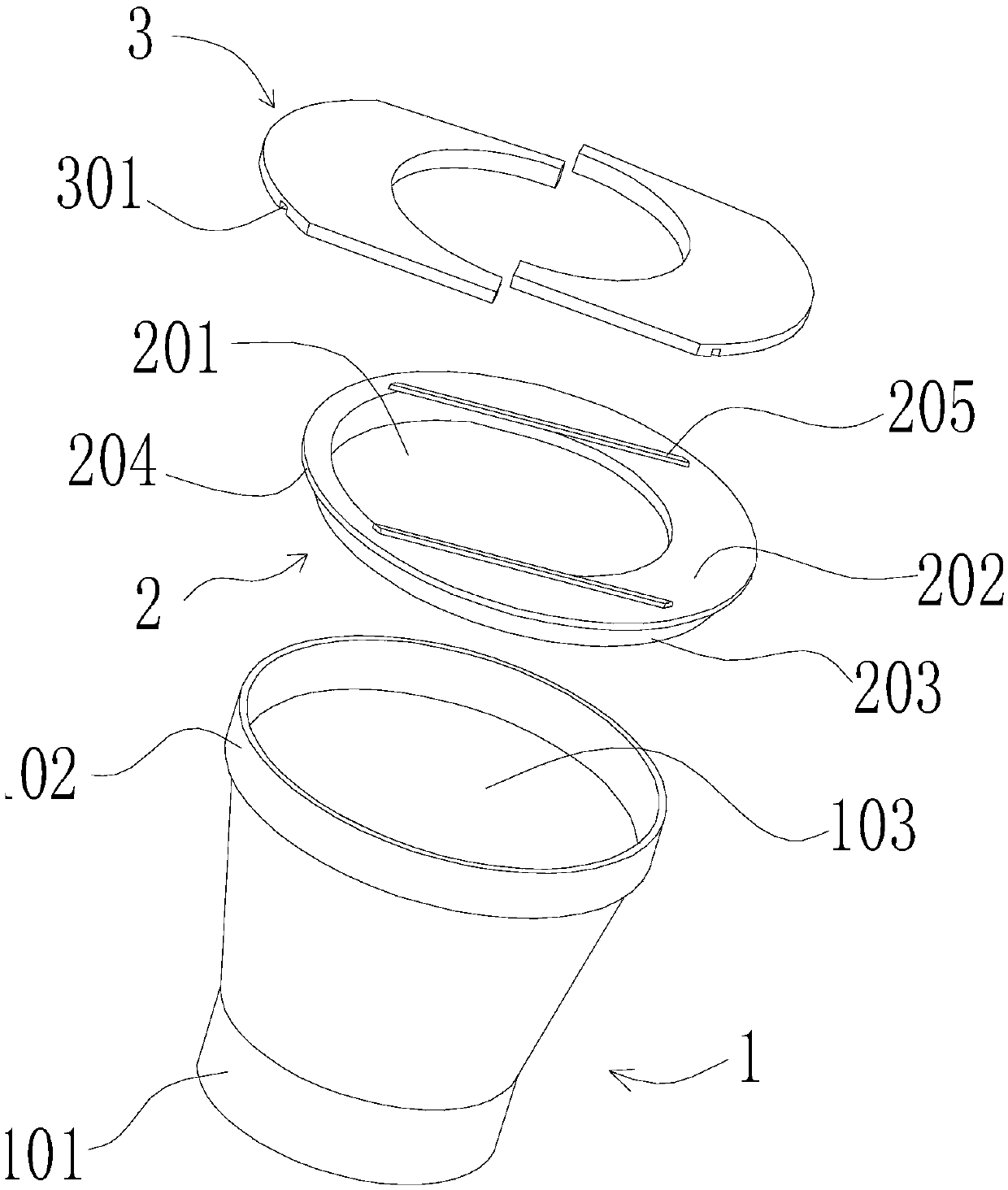

[0042] Please also refer to Figure 4 ~ Figure 7 , Figure 4 It is an exploded perspective view of Embodiment 3 of the pipe fitting connecting device of the present invention, Figure 5 yes Figure 4 top view of the seal card, Figure 6 yes Figure 4 Bottom view of the middle seal card, Figure 7 It is an assembled sectional view of Embodiment 3 of the pipe fitting connecting device of the present invention.

[0043] Embodiment 3 is a further improvement on Embodiment 2. Both the left sealing card and the right sealing card are integrally formed by arranging a plurality of flaps 307 sequentially. See Figure 5 , the main part 302 of the sealing card is plate-shaped, and the inner side of the card flap 307 is provided with a semicircular bayonet 305, and the bayonet 305 of the left sealing card and the right sealing card are docked to form a round hole, which is connected to the outer surface of the upper pipe. The diameters are equal; the bayonet 305 of the bayonet expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com