Airtightness detection device and method for fixture of filling machine

A technology of air tightness detection and liquid injection machine, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of no liquid injection, heavy workload, and unguaranteed quality of spare parts, etc. problems, to avoid air leakage and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

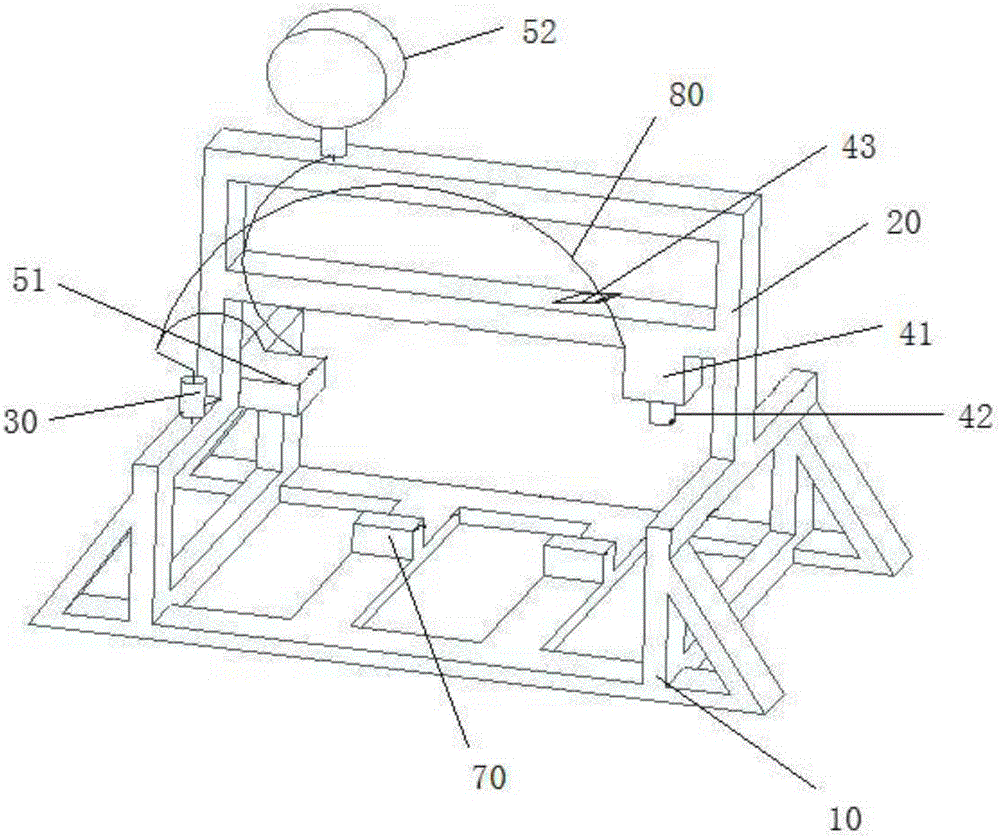

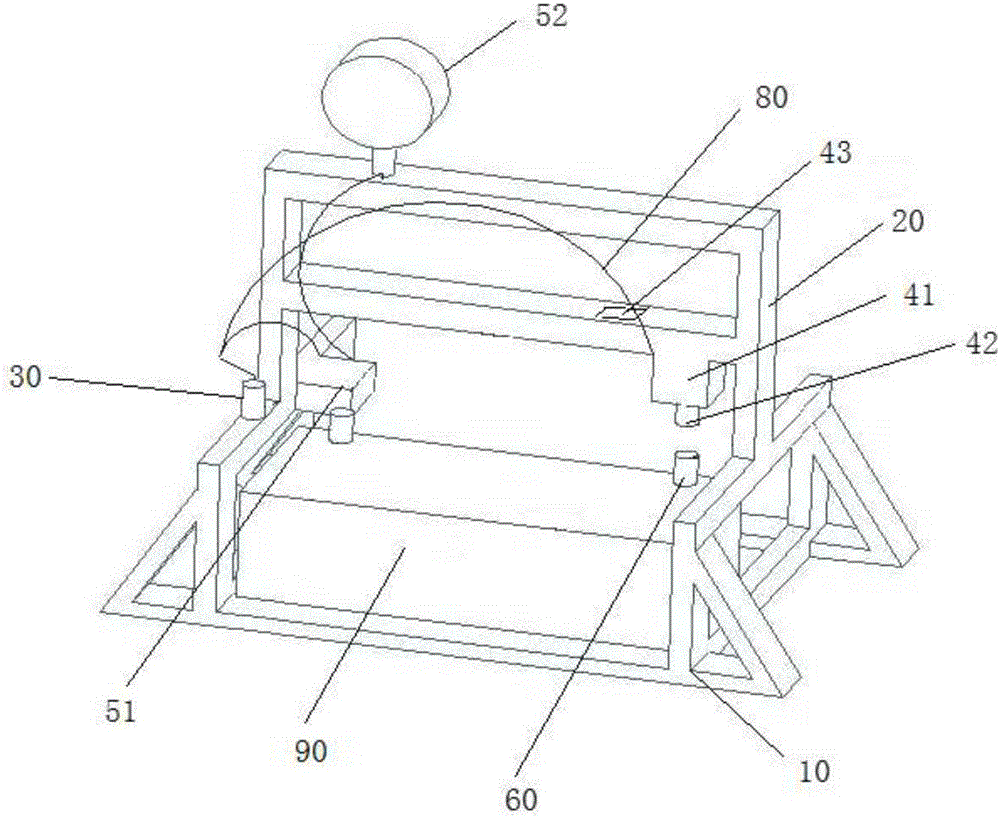

[0020] Such as figure 1 , 2 As shown, the liquid injection machine clamp airtight detection device of this embodiment includes a base 10 and a bracket 20 fixed on the base 10. The base 10 is provided with an installation groove matching the size of the clamp, and the bracket 20 is provided with an airtight seal. The detection device, the air pressure regulating mechanism 30 and the vacuum generating device, the air pressure regulating mechanism 30, the vacuum generating device and the air-tight detection device communicate with each other through the tee and the pipeline 80; The elastic nozzle 42 and the control mechanism 43 for controlling the movement of the cylinder 41, such as figure 2 As shown, during installation, the elastic air nozzle 42 is arranged opposite to the clamp air nozzle 60 .

[0021] In this embodiment, the vacuum generating device includes a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com