Pipeline performance detection device

A detection device and pipeline performance technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of deviation of the detection results of the detection device, internal detection of the detection device pipeline, and the inability to locate the detection device. Convenience, easy installation and disassembly, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

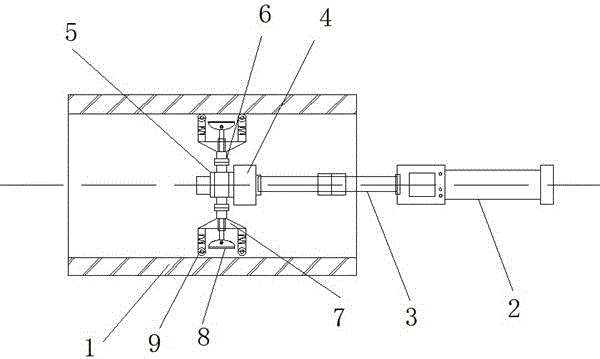

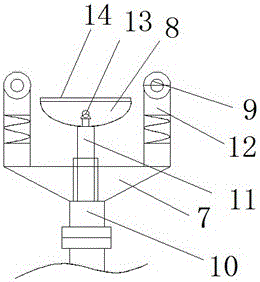

[0014] Embodiment 1: as figure 1 and 2 A pipeline performance detection device is shown, the detection device includes a hand-held rod 2, a connecting rod 3 and a detection end, the hand-held rod 2 is connected to the detection end through the connection rod 3, and the detection end is controlled by the base 4. Composed of an electric rotating shaft 5 and a detection bracket 6, the electric rotating shaft 5 is movably installed on the base 4, one end of the detection bracket 6 is connected to the electric rotating shaft 5 through a telescopic rod 10, the other end of the detection bracket One end is provided with an arc-shaped detection head 7, and the outside of the detection head 7 is provided with a plurality of transmission rollers 8 with elastic support rods 12. The inside of the detection head 7 is provided with an arc-shaped elastic sealing sleeve 8, and the elastic sealing sleeve 8 The inside is provided with a detection light source 13 and a signal sensor, the outsid...

Embodiment 2

[0015] Embodiment 2: as figure 1 and 2 As shown, the two ends of the connecting rod 3 are provided with flexible connecting ends, and the connecting rod 3 is movably installed between the hand-held rod 2 and the base 4; the connecting rod 3 is a detachable structure, according to the actual length of the pipeline 1 and the Shape, choose the connecting rod 3 of different specifications, the scope of application is wide, and the installation and dismounting operation of device is convenient at the same time.

Embodiment 3

[0016] Embodiment 3: as figure 1 and 2 As shown, the connecting rod 3 is an elastic connecting rod that can be bent into any shape; since the pipe 1 itself cannot be all linear, when there is a corner in the pipe 1, the bendable connecting rod 3 makes the detection end The head can move normally in the elbow 1 to meet different detection requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com