A method for controlling the number of modules in a parallel power supply system

A technology of power supply system and quantity control, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems such as the method of controlling the number of parallel power supply system modules that have not been found, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

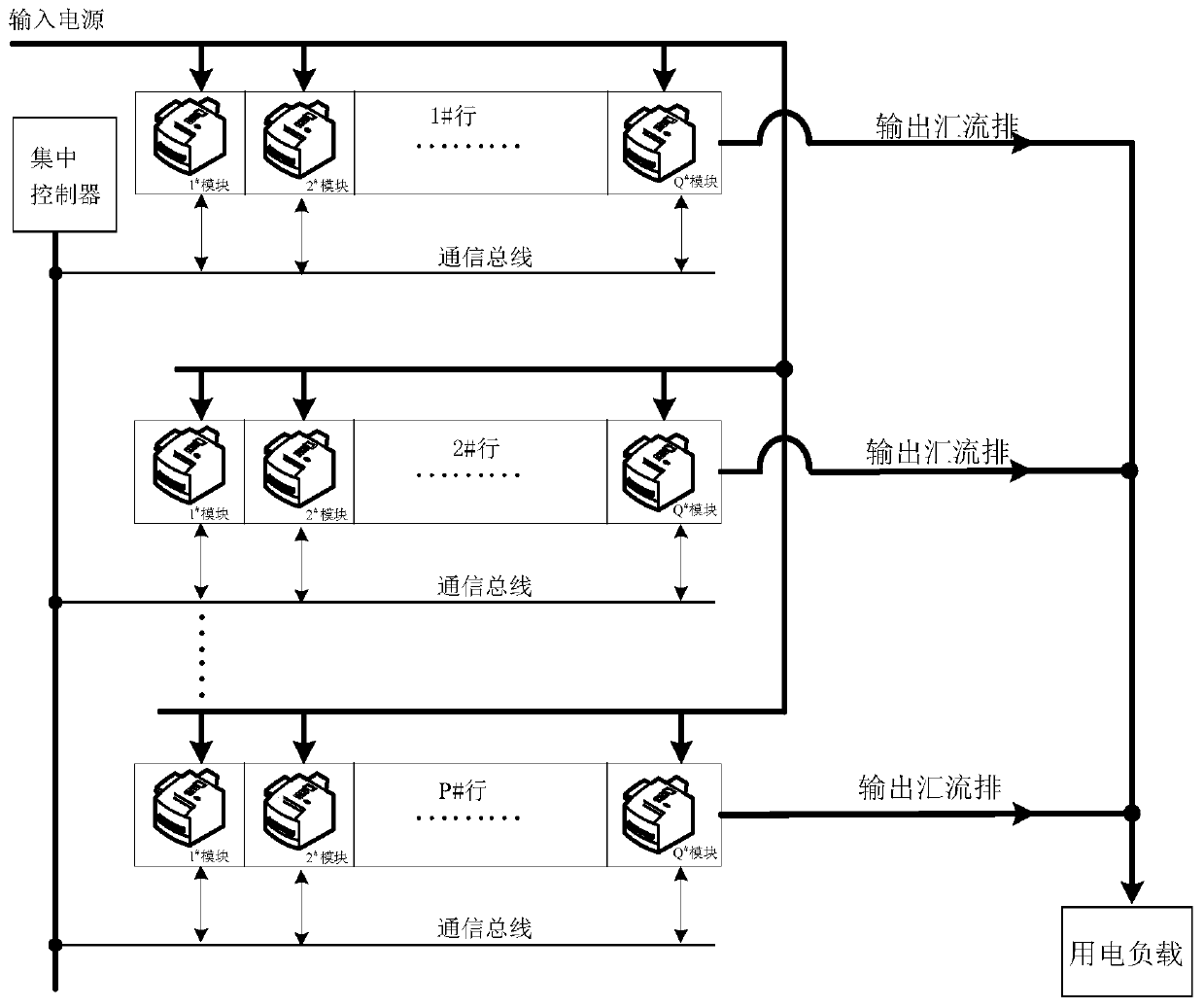

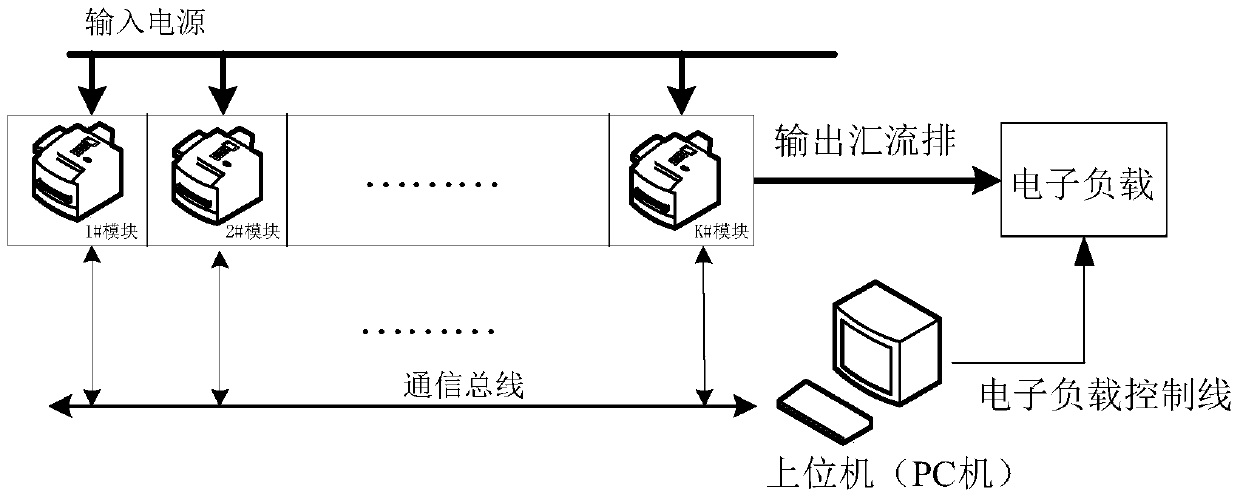

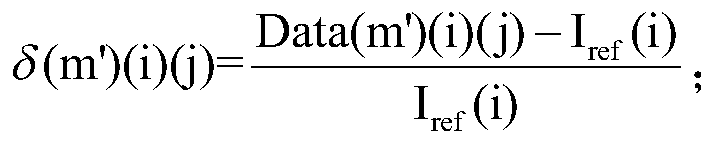

[0046] The present invention provides a method for controlling the number of modules in a parallel power supply system based on the standard deviation matrix column of current sharing and the minimum, figure 1 Shown is the structure diagram of parallel power supply system, figure 2 Shown is the structure diagram of the parallel power supply system current sharing performance data test system. figure 1 It mainly includes centralized controller of parallel power supply system, power module and electric load. The centralized controller obtains the IP of the online working module and its output current through the communication bus, and controls the number of online power supply modules; the power supply module mainly implements power supply to the load, receives the operation control command of the centralized controller and uploads the output current; the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap