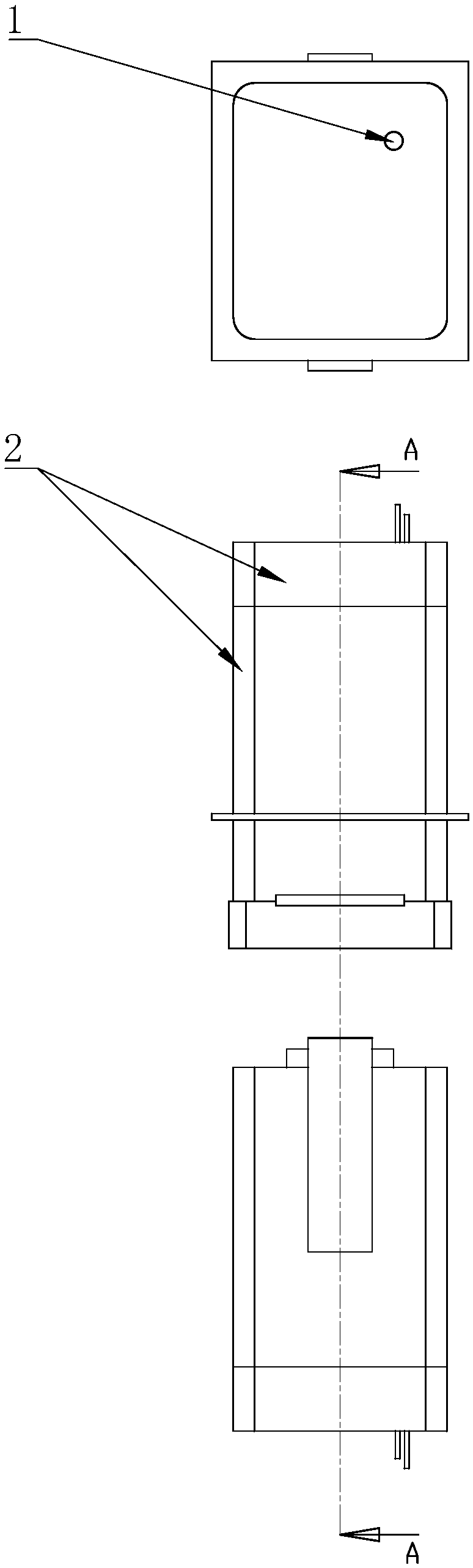

Electric vehicle charging gun plug connector

A technology for electric vehicles and charging guns, applied in the connection, circuit, electrical components and other directions, can solve the problems of inability to achieve zero wire and live wire sealed connection, uncontrollable contact area, personal safety accidents, etc., to achieve convenient and flexible insertion and removal, The effect of good contact and high over-power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

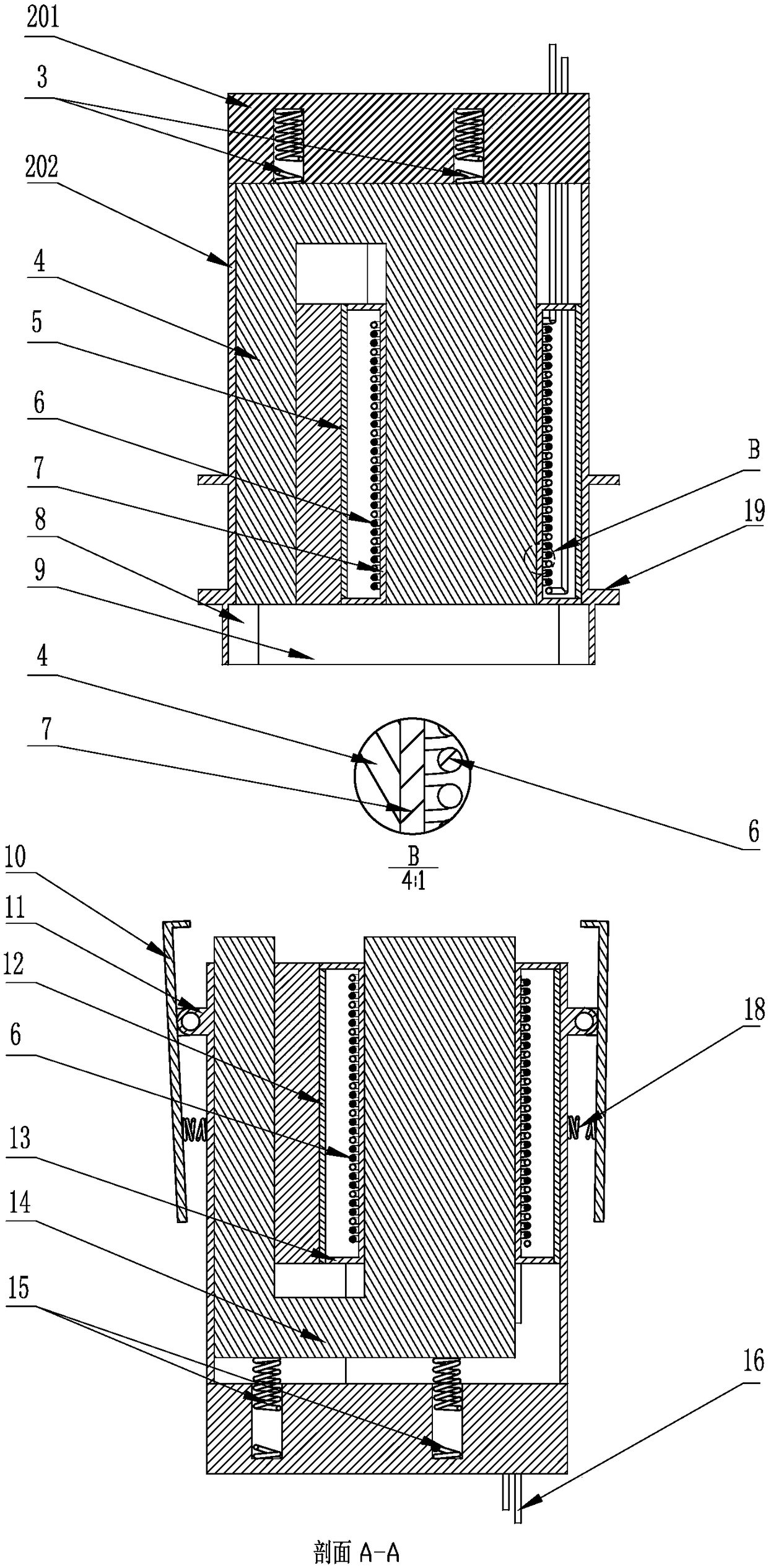

[0044] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

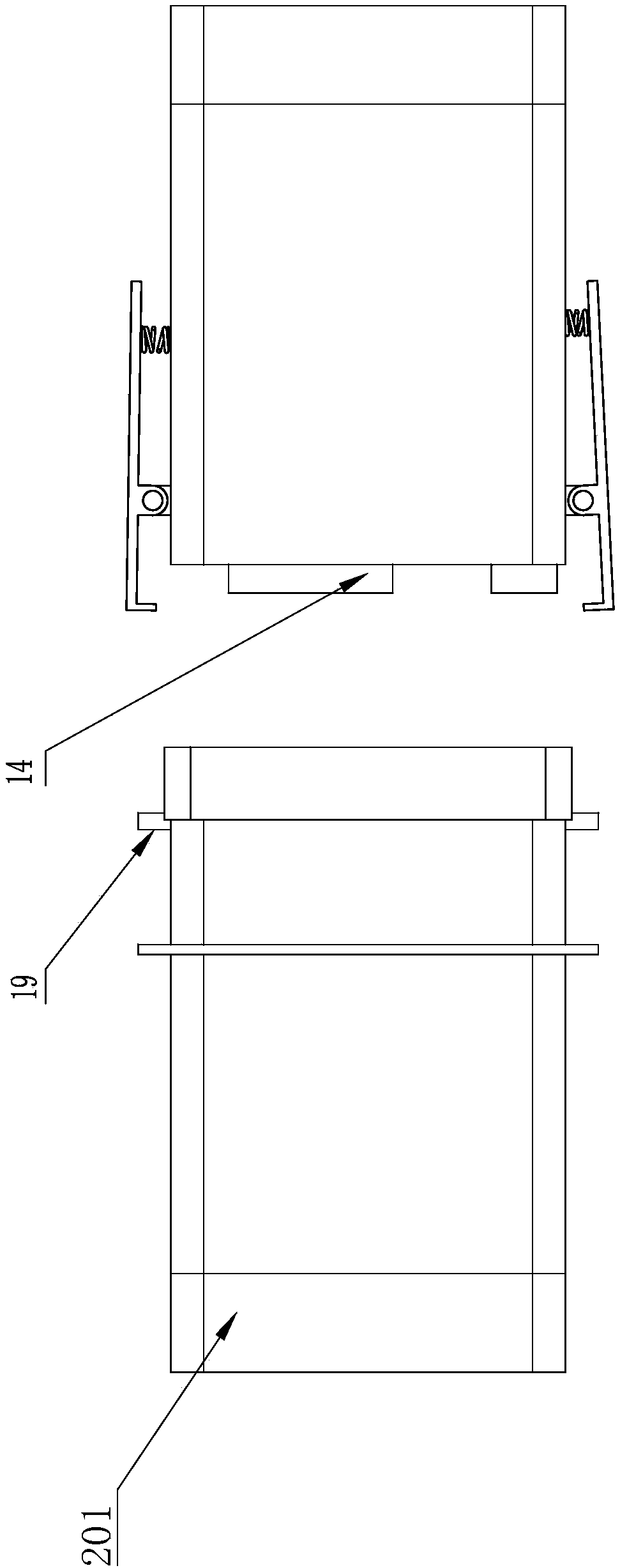

[0045] Elastic bodies are installed in one or both of the female plug and the male plug; elastic body positions are reserved in one or both of the female plug and the male plug.

[0046]An electric vehicle charging gun type plug joint, comprising: a female plug, a male plug, and a tightening device. It is characterized in that: the female plug is wound with a coil 6 on the female plug-in coil winding case 7, the female plug-in coil winding case 7 is installed in the female plug-in coil sealing case 5, the coil 6, the female plug-in coil sealing case 5. The female plug-in coil winding case 7 is set on the female plug-in magnetic core 4. The female plug-in magnetic core 4 is slidingly connected with the female plug-in coil winding case 7. The female plug-in magnetic core hole is parallel to the female plug-in coil winding case 7. The inserting magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com